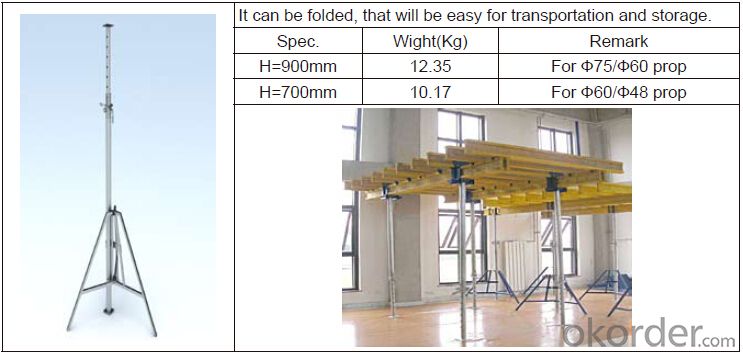

Steel Prop & Tripod for build formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel Prop & Tripod & Beam Clamp

(1) Steel prop is a vertical support system widely used in construction.

Characteristics:

◆ Simple & flexible structure

◆ Easy & fast operation

◆ Economical efficiency

◆ Easy storage and transportation

◆ Reasonable load-bearing capacity

(2) Tripod is always used as support for steel prop.

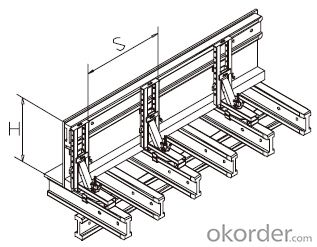

(3) The beam clamp is a technical instrument for supporting beam formwork

which makes conventional beam formwork simple, and increases the construction

efficiency.

Characteristics:

◆ Flexible structure

◆ Optimum design proposal

- Q: Can steel props be used for temporary support in railway construction?

- Yes, steel props can be used for temporary support in railway construction. Steel props are commonly used in construction projects to provide temporary support to structures until they are able to support themselves. In railway construction, steel props can be used during the installation of new tracks, bridges, or tunnels. They can be used to support the weight of heavy machinery or equipment during the construction process. Steel props are strong, durable, and easily adjustable, making them an ideal choice for temporary support in railway construction.

- Q: How do steel props contribute to the prevention of concrete slab deflection?

- Steel props are vertical supports that are commonly used in construction to provide temporary support and stability to concrete slabs during the curing process. These props play a crucial role in preventing concrete slab deflection. Firstly, steel props provide additional structural support to the concrete slab, especially in areas where the concrete is still setting and has not gained its full strength. This prevents the slab from sagging or deflecting under its own weight, ensuring that it remains level and in the desired position. Moreover, steel props are adjustable in height, allowing construction workers to raise or lower them as needed to maintain the desired level of the concrete slab. This adjustability helps to counteract any potential deflection caused by uneven ground or substandard support. Furthermore, steel props distribute the load evenly across the concrete slab, minimizing stress concentrations that could lead to deflection. By supporting the slab at multiple points, the props help to evenly distribute the weight and prevent any localized areas of excessive load, which can cause deflection. In addition, steel props provide stability and prevent lateral movement of the concrete slab. This is particularly important during the curing process when the concrete is still vulnerable to shifting or settling. The props help to keep the slab in place and ensure that it sets properly without any significant deflection. Overall, steel props are essential in preventing concrete slab deflection by providing additional support, adjustability, load distribution, and stability. Their use during the construction process ensures that the slab remains level, structurally sound, and meets the required standards for deflection control.

- Q: Are steel props suitable for supporting temporary art installations or sculptures?

- Steel props offer a reliable and versatile solution for supporting temporary art installations or sculptures. They are suitable because steel is known for its strength, durability, and load-bearing capacity. These qualities make it an ideal choice for supporting heavy and intricate artworks. Additionally, steel props can be easily customized to meet the specific requirements of the installation or sculpture. They can provide stability, balance, and secure placement, ensuring the artwork remains safely supported throughout its display period. Moreover, steel props allow for flexibility as they can be adjusted in height and angle, allowing for optimal viewing angles. In conclusion, steel props guarantee the safety and longevity of temporary art installations or sculptures.

- Q: What are the common sizes and lengths available for steel props?

- The sizes and lengths of steel props available vary depending on the manufacturer and region. However, there are standard dimensions widely found in the market. Steel props, also called adjustable scaffolding props, are commonly used in construction and formwork applications to provide support during the construction process. Regarding sizes, steel props typically come in different diameters, ranging from 40mm to 60mm. The most commonly used diameter is 48mm, which offers a good balance between strength and weight, making it suitable for most construction projects. In terms of lengths, steel props are available in adjustable ranges. The lengths can vary from 1 meter to 5 meters or more. The most frequently used lengths are 2 meters, 3 meters, and 4 meters, providing versatility and flexibility in supporting various heights and structures. It is important to note that some manufacturers may offer customized sizes and lengths based on specific project requirements. These customized options can meet unique construction needs, such as supporting heavier loads or accommodating irregular structures. When choosing steel props, it is crucial to consider the load-bearing capacity and the specific requirements of the project. It is advisable to consult construction professionals or suppliers to determine the appropriate size and length of steel props needed for a particular project.

- Q: Can steel props be used in the installation of heavy machinery?

- Yes, steel props can be used in the installation of heavy machinery. Steel props are sturdy and provide strong support, making them suitable for handling the weight and ensuring stability during the installation process.

- Q: How do steel props compare to timber beams?

- Steel props and timber beams have their own distinct advantages and disadvantages. Steel props are generally stronger and more durable than timber beams, as they can bear heavier loads and are less prone to warping or rot. They also offer adjustable height options, making them more versatile for various construction projects. On the other hand, timber beams are often more cost-effective and easier to work with due to their lighter weight and availability. They also have a more natural aesthetic appeal and provide better insulation properties. Ultimately, the choice between steel props and timber beams depends on factors such as budget, load requirements, project duration, and desired aesthetics.

- Q: Are steel props safe to use in construction?

- Generally speaking, construction can safely utilize steel props. These props, also known as adjustable steel props or steel acrow props, are commonly employed to stabilize and support temporary structures throughout construction endeavors. Their purpose is to provide dependable support and load-bearing capacity, ensuring the safety of workers and maintaining the structural integrity of the construction site. Steel props are crafted from high-quality steel, which imparts exceptional strength and durability. They are designed to withstand substantial loads and offer adjustable height options, making them adaptable for diverse construction applications. Additionally, steel props are equipped with safety features like locking pins or clips to prevent inadvertent collapse or adjustment. Furthermore, steel props undergo rigorous testing and conform to industry standards to guarantee their safety and reliability. They are typically manufactured in accordance with recognized regulations and guidelines, such as those established by the Occupational Safety and Health Administration (OSHA) in the United States or the European Standard EN 1065. These standards ensure that steel props meet specific criteria for load capacity, stability, and safety. However, it is important to note that the safety of steel props also hinges on proper installation, maintenance, and usage. It is crucial to adhere to the manufacturer's instructions and guidelines when setting up, adjusting, and dismantling steel props. Regular inspections and maintenance should be conducted to identify any indications of wear, damage, or corrosion that may compromise their safety. In conclusion, when utilized correctly and in accordance with safety guidelines, steel props are deemed safe for use in construction. Their sturdy construction, adjustable height options, and adherence to industry standards make them a dependable choice for supporting temporary structures during construction projects.

- Q: Are steel props suitable for supporting temporary platforms for events?

- Yes, steel props are suitable for supporting temporary platforms for events. Steel props, also known as adjustable steel props or acrow props, are commonly used in construction and temporary structures due to their strength and stability. They are made from high-quality steel and have adjustable heights, allowing them to provide sturdy support for various platform sizes and weights. Steel props are easy to set up and dismantle, making them ideal for temporary platforms used in events such as concerts, exhibitions, and festivals. They can withstand heavy loads and offer reliable structural support, ensuring the safety of performers, attendees, and equipment. Additionally, steel props are durable and can withstand outdoor conditions, making them a reliable choice for temporary platforms used in both indoor and outdoor events.

- Q: Are steel props suitable for supporting concrete slabs?

- Yes, steel props are suitable for supporting concrete slabs. Steel props, also known as adjustable steel props or acrow props, are commonly used in construction to provide temporary support for concrete slabs during construction or renovation. They are designed to be adjustable in height and can be easily installed and removed. Steel props are made of high-quality steel, which provides them with strength and durability. This makes them capable of withstanding the weight of concrete slabs and other construction materials. They are able to support the load and distribute it evenly, ensuring the stability of the concrete slab. Furthermore, steel props offer flexibility in terms of height adjustment. They have a telescopic design that allows for easy extension and retraction, making them suitable for supporting concrete slabs of various thicknesses. The ability to adjust their height also enables construction workers to easily level the slabs and ensure a smooth and even surface. In addition to their strength and adjustability, steel props are also easy to handle and transport. They are lightweight and can be easily moved around the construction site, making them a convenient choice for supporting concrete slabs in different areas. Overall, steel props are a suitable and reliable choice for supporting concrete slabs. Their strength, adjustability, and ease of use make them a popular option in the construction industry.

- Q: Can steel props be used in the construction of exhibition halls?

- Yes, steel props can be used in the construction of exhibition halls. Steel props are commonly used in construction projects to provide temporary support and stability to structures, and they can be especially useful in exhibition halls where large open spaces and flexible layouts are required. Steel props offer strength, durability, and the ability to adjust their height, making them suitable for supporting heavy loads and accommodating various exhibition setups.

Send your message to us

Steel Prop & Tripod for build formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords