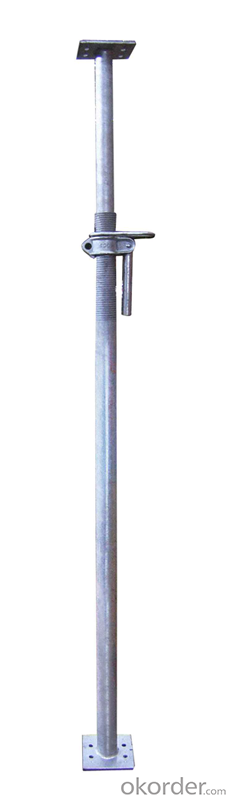

Heavy Duty Steel Prop of Scaffolding System

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Steel Props:

1. Steel Prop consists of internal pipe, external pipe, prop sleeve, nut, pin, top and bottom plate.

2. Steel Prop is widely used as support system in beam, slab, formwork, concrete and floor support.

3. Steel Prop can be surface treatment red oil painting or powder coated or galvanized to further resist rust, cracking and corrosion, has no pollution or harm to the environment and human body, which make sure of its low damage and longer life span.

4. Steel Prop has fewer components, easy and quick assembly.

5. Steel Props has high bearing capacity, as steel pipe material is Q235, thickness can be 1.8mm to 3.0mm, diameter 40-48mm,48-56mm,48-60mm. According to SGS test report, one prop with 2.2mm of thickness, 48-60mm diameter can load 1.8tons, which is heavy duty Steel Props .

6.We can meet all kinds of steel props , Italian tye, Spanish type for South Amercia, Middle East type. aole the requiremnets, such as U head, fork head, rosette head, plate, etc.

Technical parameters

Model Number: adjustable steel prop

Material: Q235 steel tube raw material

Surface Treatment: Galvanized,Dip Painted,Powder coated

Color: silver,dark red,yellow,blue,green and more colore

Application: building construction shoring props for inside concrete wall support

tube thickness: 1.8/2.0/2.2/2.5/3.0mm

adjustable length: 1600-2900/1800-3200/2000-3600/2200-4000mm as your request

base plate size: 120*120*5mm or as your request

Working life: 4-6 years normally

inner tube diameter: 40mm,or 48mm

outer tube diameter: 48mm,or 56/58/60mm

Packaging & Delivery

In bulk or steel pallet. props will be bundle with wooden pallet or bare package in container one 20ft container can load steel props 1800pcs to 2500pcs.

20 to 30 days to main port of China after order confirmation

- Q: Can steel props be used for both vertical and horizontal support?

- Steel props can be used for both vertical and horizontal support. Steel props, also known as adjustable steel props or steel shoring props, are commonly used in construction projects to support formwork, beams, and slabs. These props are designed to withstand heavy loads and provide stability and safety during construction activities. In vertical support, steel props are used to bear the weight of the concrete slab or formwork above. They can be adjusted to the desired height, allowing for flexibility in construction. The vertical support provided by steel props helps distribute the load evenly and prevents any sagging or collapsing of the structure. In horizontal support, steel props are used to provide lateral stability to the formwork or beams. By placing steel props at regular intervals along the horizontal axis, they help maintain the alignment and prevent any deformation or misalignment of the structure. This is particularly important in situations where there is a need for additional support due to heavy loads or unstable ground conditions. Overall, steel props are versatile and can be used for both vertical and horizontal support. Their adjustable nature makes them suitable for various construction scenarios where temporary support is required. However, it is important to ensure that the steel props are properly installed and used within their load-bearing capacity to ensure the safety and stability of the structure.

- Q: Are steel props adjustable in small increments for precise leveling?

- Steel props have the ability to be adjusted in small increments, allowing for precise leveling. They are commonly used in construction projects to provide temporary support and stability to beams, walls, and ceilings. These props, also known as adjustable steel props or scaffolding props, consist of two main components - an outer tube and an inner tube. The inner tube can be adjusted to different heights, enabling the supported structure to be leveled accurately. The adjustment process involves rotating a threaded collar on the outer tube, resulting in the inner tube moving up or down in small increments. This adjustability feature makes steel props an exceptional choice for achieving exact and precise leveling in construction projects.

- Q: How are steel props installed and removed?

- Steel props are installed by first determining the appropriate height and spacing required for support. The props are then positioned vertically, aligned with the load-bearing structure, and adjusted to the desired height using a screw mechanism. Once in place, the props are secured by tightening the screw mechanism. To remove steel props, the process is reversed. The screws are loosened to lower the props to their original position, and then they are carefully lifted and removed from the structure. It is crucial to follow safety guidelines and ensure proper handling during both installation and removal to prevent any accidents or damage to the surrounding structures.

- Q: What is the weight of a standard steel prop?

- The weight of a standard steel prop can vary depending on its size and specifications. On average, a typical steel prop can weigh around 25 to 30 pounds.

- Q: Are steel props adjustable for supporting curved structures?

- Yes, steel props are adjustable for supporting curved structures. Steel props, also known as adjustable steel props or acrow props, are versatile and can be used to support various types of structures, including curved ones. These props consist of two main parts: an outer tube and an inner tube, which can be adjusted to the desired height and locked in place using a pin or a screw mechanism. This adjustability allows the props to accommodate the specific shape and curvature of a structure, providing reliable support and stability. Additionally, steel props are typically made of strong and durable materials, such as steel, which makes them capable of withstanding the weight and load of curved structures. Therefore, steel props are an ideal choice for providing adjustable support to curved structures during construction, renovation, or any other application where temporary support is required.

- Q: Can steel props be customized for specific project requirements?

- Yes, steel props can be customized for specific project requirements. Steel props, also known as adjustable steel props or steel support props, are commonly used in construction projects to support temporary structures or provide temporary support to existing structures. These props can be adjusted to different heights and are versatile in their applications. Steel props can be customized in various ways to meet specific project requirements. Firstly, they can be manufactured in different sizes and load capacities to support different types of structures and loads. This ensures that the props are strong enough to withstand the weight and pressures they will be subjected to during the construction process. Secondly, steel props can be customized with additional features to enhance their functionality. For example, props can be designed with adjustable heads to provide flexibility in supporting different angles or surfaces. They can also be equipped with leveling mechanisms, such as threaded screws or hydraulic systems, to ensure precise and stable support on uneven or sloping surfaces. Furthermore, steel props can be customized with specific surface finishes or coatings to enhance their durability and longevity. Surface treatments such as galvanization or powder coating can be applied to protect the props from corrosion or rust, making them suitable for outdoor or harsh environments. Additionally, the length of steel props can be adjusted according to the specific height requirements of the project. This allows for a precise fit and ensures that the props provide adequate support without being too short or too long. In summary, steel props can be customized in terms of size, load capacity, additional features, surface finish, and length to meet the specific project requirements. This customization ensures that the props are fit for purpose, providing effective support and contributing to the successful completion of the project.

- Q: Can steel props be used in hotel construction?

- Yes, steel props can be used in hotel construction. Steel props are commonly used in construction projects, including hotel construction, to provide temporary support to structures during the construction process. They are versatile, adjustable, and capable of supporting heavy loads, making them suitable for use in hotel construction.

- Q: Are steel props suitable for temporary structures?

- Temporary structures can be supported by steel props, also called adjustable steel props or acrow props. These props are commonly used in construction projects to provide stability and load-bearing capacity for structures like formwork, scaffolding, and shoring systems. The versatility of steel props lies in their adjustable height feature, which allows them to support different structures precisely. Made from high-quality steel, these props are durable and strong, capable of handling heavy loads and providing reliable temporary support. In terms of efficiency, steel props are easy to install and dismantle. They can be quickly adjusted to the desired height and removed once the temporary structure is no longer needed. This flexibility and user-friendliness have made them a popular choice in the construction industry. However, it is crucial to consider factors such as the size, weight, and duration of use when determining the suitability of steel props for temporary structures. Consulting with a structural engineer or construction professional is always advised to ensure the proper selection and usage of steel props for such projects.

- Q: Can steel props be used in mining projects?

- Yes, steel props can be used in mining projects. Steel props, also known as temporary supports or temporary roof supports, are commonly used in underground mining operations to provide temporary structural support to the roof and walls of mine tunnels or shafts. These props are made of high-strength steel and are designed to withstand the weight and pressure exerted by the surrounding rock and soil. They are adjustable in length, allowing for easy installation and removal as the mining activities progress. Steel props are an essential component of mine safety, as they help to prevent roof collapses and ensure the stability of the underground workings.

- Q: Are steel props adjustable from both ends?

- Yes, steel props are typically adjustable from both ends.

Send your message to us

Heavy Duty Steel Prop of Scaffolding System

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords