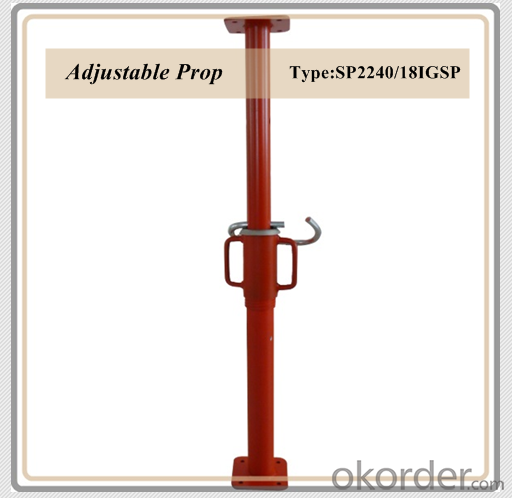

Export Adjustable Props /painted surface steel prop / telescopic steel prop / red color prop 2.2-4M

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1680 Piece/Pieces pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description

1. Length 2200-4000mm

2. Outer tube diameter 56mm

3. Inner tube diameter 48mm

4. Tube material : Q235

5. Tube thickness : 1.8mm

6. weight : 10kgs

7. square plate : 120*120*4mm

8. Italian type nut

9. G-pin 12

10. Painted surface

11. Color : as customer 's request . red / blue / green / orange/ brown

Packaging & Delivery

| Packaging Details: | packaging :50pcs / bale container : 1680pcs / 20ft |

|---|---|

| Delivery Detail: | 20-30days after receive deposit |

Specifications

Adjustable props / construction prop

Height 2.2-4M

Italy type painted props

Adjustable props

Shoring props

Construction scaffold steel prop

Scaffold props

Telescopic steel props

Product introduce

Steel Prop is a labour and time saving device to support shuttering and centering.

It is made outer tube of 60mm (O. D.) & inner pipe of 48mm (O. D.)

or outer tube 56mm (O.D.) & inner pipe 48mm (O.D.) ,

or outer tube 48mm (O.D.) & inner pipe 40 mm (O.D.) moving in each other telescopically.

The surface has painted , powder , electric galvanized and hot dipped galvanized .

The height use of props by double staging is recommended upto 7000mm only .

Top and bottom plate are provided with nail holes for wooden beam or steel beam .

The top has square shape , flower shape or U-head , U-fork head .

U-head can use fix or adjustable .

- Q: Are steel props suitable for temporary or permanent structures?

- During construction or repair work, it is common to utilize steel props to temporarily support structures. These props are specifically engineered to withstand heavy loads and ensure stability until the structures can bear their own weight. Although steel props are mainly intended for temporary purposes, they can also be suitable for certain permanent structures. In situations where additional strength or reinforcement is necessary, steel props may be employed as permanent supports in buildings or structures. Nevertheless, the appropriateness of steel props for permanent structures relies on several factors including design requirements, load-bearing capacity, and project-specific needs. To determine whether steel props are suitable for a particular permanent structure, it is crucial to seek guidance from a structural engineer or construction industry professional. Ultimately, the decision to use steel props for temporary or permanent structures should be based on a thorough evaluation and consideration of the project's specific requirements and conditions.

- Q: What is the typical weight of a steel prop?

- The typical weight of a steel prop can vary depending on its size and specific design. However, a standard steel prop used in construction projects typically weighs between 20 to 40 pounds.

- Q: Can steel props be used in the construction of temporary bridges?

- Yes, steel props can be used in the construction of temporary bridges. Steel props provide strong support and stability to the bridge structure, making them suitable for temporary constructions where durability and safety are essential.

- Q: Can steel props be used in the construction of libraries?

- Yes, steel props can be used in the construction of libraries. Steel props, also known as adjustable steel props or steel scaffolding props, provide temporary support to structures during construction or renovation work. They are commonly used to support ceilings, walls, and beams, ensuring stability and safety. In the construction of libraries, steel props can be utilized to provide additional support during the installation of heavy bookshelves, mezzanines, or other structural elements.

- Q: Can steel props be used for supporting elevated walkways and platforms?

- Yes, steel props can be used for supporting elevated walkways and platforms. Steel props are commonly used in construction to provide temporary support for structures. They are adjustable and can be easily installed to bear the weight of elevated walkways and platforms, ensuring their stability and safety.

- Q: Are steel props suitable for supporting temporary pipe systems?

- Yes, steel props are suitable for supporting temporary pipe systems. Steel props, also known as adjustable steel props or steel shoring props, are commonly used in construction and temporary support applications. They are designed to provide stability and support to vertical loads, making them ideal for supporting temporary pipe systems. Steel props are versatile and can be easily adjusted to the desired height, allowing for flexibility in the installation of temporary pipe systems. They are known for their strength, durability, and load-bearing capacity, which make them a reliable choice for supporting the weight of pipes and ensuring the stability of the temporary system. Additionally, steel props are easy to install and dismantle, making them a convenient option for temporary pipe installations.

- Q: Can steel props be used for bridge construction?

- Yes, steel props can be used for bridge construction. Steel props are commonly used in construction projects to provide temporary support and stability during the construction process. In bridge construction, steel props can be used to support formwork, beams, or other structural elements until they are fully secured and able to bear the load independently.

- Q: Can steel props be used for supporting underground tunnels or mines?

- Yes, steel props can be used for supporting underground tunnels or mines. Steel props are commonly used in construction and mining industries to provide temporary or permanent support to underground structures. They are designed to withstand high loads and provide stability to the tunnels or mines, ensuring the safety of workers and the infrastructure.

- Q: Are steel props adjustable in both rotation and translation?

- Steel props are capable of being adjusted in both rotation and translation. These props, also referred to as steel shore props or scaffolding props, are frequently utilized in construction ventures as temporary supports. Their purpose is to furnish stability and assistance to structures during the process of construction or renovation. Steel props consist of adjustable sections, typically constructed from steel tubes, which can be extended or retracted to attain the desired height or length. This allows for translation adjustment, permitting the props to be shifted either vertically or horizontally to accommodate diverse structural necessities. Furthermore, steel props are furnished with adjustable heads that can be rotated to facilitate rotational adjustment. This enables the props to be correctly aligned and positioned in order to sustain the load and distribute it evenly. The adaptability of steel props in both rotation and translation renders them versatile and appropriate for a variety of construction applications. They offer flexibility in the adjustment of height, length, and support angle, ensuring stability and safety during construction operations.

- Q: Can steel props be used in the construction of temporary storage or warehouse structures?

- Yes, steel props can be used in the construction of temporary storage or warehouse structures. Steel props are adjustable and robust support systems that provide stability and strength to the structure. They can be easily installed and dismantled, making them suitable for temporary structures. Steel props are capable of bearing heavy loads and ensuring the safety and durability of the temporary storage or warehouse structures.

Send your message to us

Export Adjustable Props /painted surface steel prop / telescopic steel prop / red color prop 2.2-4M

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1680 Piece/Pieces pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords