steel props of C

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description

suspended slab formwork

slab form work

concrete slab formwork

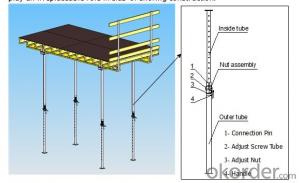

150 Aluminum Frame Early Dismantling Slab Formwork With Adjustable Prop

Description:

1. Brief introduction

Especially for projects with a large number of similar applications and open facades, Alu-slab system is the right solution. The panel is end product, no assembling on site and it is easily to build, ease of application, more important thing is, the panel is light weight, a dead lift is achieved, save time and effort.

2. Competitive advantage

① Light weight but high load bearing capacity

The panels could be transported by manual work so that it greatly reduces the aggregate cost, accelerates the erection speed, and all in all increases the aggregate benefit.

②Quickly turnover of slab panels

The early dismantling prop system speed up the turnover of the panels, minimize the investment, lower the cost, improve the working efficiency, and shorten the project period under the precondition of keeping the concrete structure and safety uninfluenced, in line with the erection requirement and ensuring the project quality.

③Cost effective with early dismantling prop system.

This early dismantling system is simple, safe and fast, saving at least 50% percent of your construction time.

3. Applications

- Q: What are the different sizes and lengths of steel props available?

- The sizes and lengths of steel props available can vary depending on the manufacturer and supplier. Generally, steel props come in a range of sizes and lengths, starting from smaller props with lengths around 1.8 meters (6 feet) and going up to larger props with lengths of 4.8 meters (16 feet) or more. These props are typically adjustable in height and can support different loads and structures based on their design and specifications. It is important to consult with a professional or refer to the specific product specifications to determine the exact sizes and lengths available for steel props.

- Q: Can steel props be used in marine construction projects?

- Yes, steel props can be used in marine construction projects. Steel props, also known as adjustable steel props or steel shore props, are commonly used in construction projects to support vertical loads. They are adjustable in height and can be used to provide temporary support during the construction of marine structures such as piers, docks, and bridges. Steel props are made of high-quality steel and have the strength and durability necessary to withstand the harsh marine environment. They can be used to support various structures and components, including formwork, scaffolding, and temporary supports for concrete pouring. Their adjustable height feature allows for easy customization and adaptation to different marine construction requirements. Furthermore, steel props can be easily installed and dismantled, making them suitable for temporary applications in marine construction projects. They provide stability and safety to the construction site, ensuring that structures are properly supported during the construction process. Additionally, steel props are resistant to corrosion, which is a crucial factor in marine construction where exposure to saltwater and other corrosive elements is common. In conclusion, steel props are a viable option for marine construction projects. Their strength, durability, adjustability, and resistance to corrosion make them suitable for supporting various structures and components in the marine environment.

- Q: Can steel props be used for supporting temporary fencing in high-security areas?

- Indeed, the utilization of steel props proves to be effective in bolstering temporary fencing in high-security zones. With their strength and durability, steel props are an optimal choice for providing stability and support to temporary fencing systems. They are capable of withstanding strong winds and other external forces, thereby guaranteeing that the fencing remains intact and delivers the necessary security. In areas where the likelihood of intrusion or unauthorized access is elevated, it becomes imperative to possess a fencing system that is steadfast and dependable. Steel props offer the advantage of easy height adjustment, affording flexibility in the installation of temporary fencing. Furthermore, their robust construction deters tampering or damage, thereby fortifying security measures. Moreover, steel props exhibit resistance to corrosion, a particularly vital characteristic in regions with inclement weather or exposure to moisture. This resistance ensures the long-lasting strength and integrity of the props, diminishing the frequency of replacements or repairs. In summary, steel props are a suitable option for supporting temporary fencing in high-security areas due to their robustness, durability, adjustability, and corrosion resistance. They establish a solid foundation for the fencing system, guaranteeing the highest level of security and protection.

- Q: What is the weight of a standard steel prop?

- The weight of a standard steel prop can vary depending on its specific size and design. However, on average, a standard steel prop typically weighs between 20 to 30 pounds (9 to 14 kilograms). It is important to note that this weight range is just an estimate, and the actual weight may differ based on factors such as the length, thickness, and load-bearing capacity of the prop. Additionally, different manufacturers may have their own variations in weight for their steel props.

- Q: How are steel props installed?

- Steel props, also known as adjustable steel props or steel acrow props, are typically installed by following these steps: 1. Positioning: Determine the appropriate location for the steel props based on the load-bearing requirements and structural support needed. 2. Adjusting: Extend or retract the prop to the desired height by turning the threaded portion of the prop tube. Ensure the prop is securely locked in place at the desired length. 3. Placing: Position the base plate of the prop on a stable and level surface, ensuring it is perpendicular to the load it will be supporting. 4. Securing: Use a hammer or mallet to strike the base plate firmly onto the surface, ensuring a stable and secure connection. 5. Checking: Verify that the prop is straight and vertically aligned with the load above. Adjust the height or reposition if necessary. 6. Locking: If required, secure the prop in place by tightening the locking collar or pin mechanism, ensuring it cannot accidentally retract or extend. 7. Rechecking: Double-check the positioning, stability, and alignment of the prop before beginning any load-bearing activities. It is important to follow the manufacturer's instructions and safety guidelines when installing steel props to ensure proper installation and safe use.

- Q: Do steel props require any additional support at the top?

- Yes, steel props typically require additional support at the top to ensure stability and load-bearing capacity. This can be achieved through the use of suitable beams, brackets, or other structural components that provide secure anchorage and prevent the props from tipping or collapsing under the weight they are supporting.

- Q: How to reinforce the lower part of the steel structure of the construction elevator on the roof of the non - air defense garage

- Channel steel is a kind of carbon steel used in construction and machinery. It is a kind of complex section steel. Channel is mainly used in building structure, curtain wall engineering, machinery and equipment and vehicle manufacturing, etc.. It is required to have good welding, riveting and comprehensive mechanical properties. The raw material for producing channel steel is carbon steel or low alloy steel billet with carbon content not exceeding 0.25%. Finished channel steel formed by hot working forming, normalizing or hot rolling. Its specifications to waist height (H) * leg width (b) * waist thickness (d) of the MM number, such as 100*48*5.3, said waist height of 100 mm, leg width of 48 mm, waist thickness of 5.3 mm channel, or 10# channel. Waist high the same channel, if there are several different leg width and waist thickness also need to be on the right side of the model plus a B C, such as 25#a 25#b, etc..

- Q: Can steel props be used in water treatment plant construction?

- Steel props, also referred to as adjustable steel props or steel shore props, can indeed be utilized in the construction of water treatment plants. These props are commonly employed in construction projects to temporarily support and stabilize structures. They possess the ability to provide vertical support and can be adjusted to accommodate various construction needs. In the context of water treatment plant construction, steel props fulfill a multitude of purposes. For instance, they can provide support to formwork during the construction of concrete structures like tanks, basins, and walls. Furthermore, steel props are ideal for temporarily supporting heavy machinery and equipment during installation or maintenance tasks. The utilization of steel props in water treatment plant construction is favored due to their inherent strength and durability. Crafted from high-quality steel, they are capable of withstanding the challenging conditions typically found in water treatment plants, including exposure to moisture, chemicals, and high humidity. Additionally, these props can be easily adjusted and securely fastened, ensuring precise positioning and alignment of structures, pipes, or equipment. Nevertheless, it is crucial to consider the specific requirements and regulations of the water treatment plant project when implementing steel props. Factors such as load capacity, corrosion resistance, and adherence to safety standards must be thoroughly assessed to guarantee the appropriate and safe utilization of steel props in water treatment plant construction.

- Q: Can steel props be used in the construction of manufacturing facilities?

- Yes, steel props can be used in the construction of manufacturing facilities. Steel props, also known as steel shores or acrow props, are adjustable supports that are commonly used in construction to provide temporary support during the building process. They are made of steel and have a telescopic design, allowing them to be adjusted to the required height. In the construction of manufacturing facilities, steel props can be used in various ways. One of the main applications is to support formwork or scaffolding systems. Formwork is used to create the molds or frames for pouring concrete, while scaffolding is used to provide a safe working platform for workers. Steel props are used to provide additional support to these structures, ensuring stability and safety during the construction process. Steel props can also be used to support heavy loads or equipment during the installation phase. Manufacturing facilities often require the installation of heavy machinery, equipment, or production lines. Steel props can be used to provide temporary support while these installations are being carried out, ensuring that the load is properly distributed and preventing any potential accidents or damages. Furthermore, steel props can be used to support temporary structures such as mezzanines, walkways, or platforms. These structures are commonly used in manufacturing facilities to maximize space utilization and create additional working areas. Steel props provide the necessary support to ensure the stability and safety of these temporary structures. Overall, steel props are versatile and reliable temporary support systems that can be used in the construction of manufacturing facilities. They play a crucial role in ensuring the stability, safety, and efficiency of the construction process, making them an essential component in the successful completion of manufacturing facility projects.

- Q: Steel support can not be removed if the deformation of the foundation pit, how to solve

- Specific analysis of specific issues, but also combined with the value of your pit observation

Send your message to us

steel props of C

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords