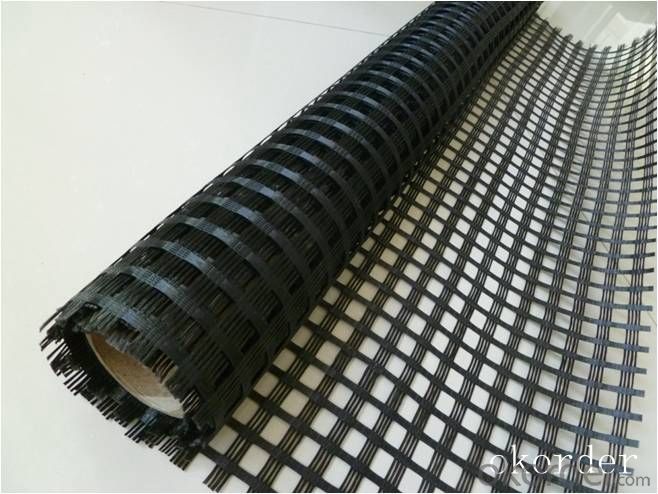

Us200 Geotextile Steel Plastic Geogrids Biaxial for Civil Engineering Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction

The Steel plastic composite geogrid is by the high tensile steel wire, after the special handing, with the polyethylene(P. E), and increase other assistants, though squeezes out causes it excel to become the mult-skill anti-to pull the banding, and the surface has the rough embossing, for excel in reinforcement earthwork belt. From this as soon as the single belt, after vertical, according to decides the spacing knitting horizontally or clamps gathers the arrangement, uses the ultrasonic welding to molding.

20X20,30X30,40X40,50X50,60X60,70X70,80X80,90X90,

100X100KN

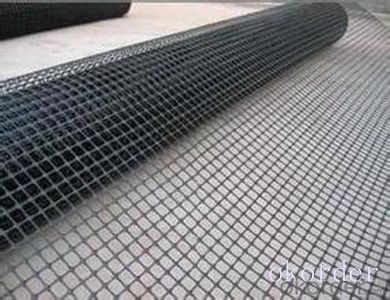

PP geogrid

20X20,30X30,40X40,50X50,60X60,70X70,80X80,90X90,

100X100,110x110KN

Production function

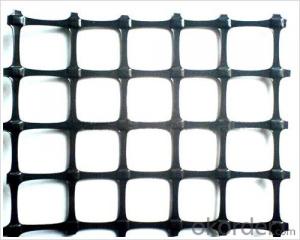

1:Tensile strength, high creep degeneration small, it has good flexibility, low elongation at break, and effectively solved the engineering distortion and quite a shift, adapt to the environment soil, and can meet the retaining wall of high grade highway tall role.

2:Effectively improve the bearing the reinforcement embedded locks, bite role, great enhancement the bearing capacity of the foundation, effective constraint of soil lateral displacement, enhance the foundation stable performance.

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: Geotextile how to construction?

- Geotextile construction is relatively simple with artificial roll: cloth to be flat, and appropriate to leave the deformation margin. The installation of filament or short wire geotextiles is usually carried out by means of lap, suture and welding. The width of the stitching and welding is generally 0.1 m or more, and the lap width is generally 0.2 m or more. May be exposed to long-term geotextile. It should be welded or stitched. All suture centers need to be carried out continuously (for example, spot joints are not allowed). Before the overlap, the geotextile must overlap at least 150mm. The minimum stitch is at least 25 mm from the weaving edge (the edge of the material exposed). Stitching the seam of the soil includes the first line and the line of the chain. The line used for suturing should be a resin material with a minimum tension of more than 60N. And with geotextile quite or beyond the anti-chemical corrosion and anti-ultraviolet ability. Any "missing needle" on the sewn geotextile must be re-sewn in the affected area. It is necessary to take appropriate measures to prevent the soil, particulate matter or foreign matter from entering the geotextile after installation.

- Q: Can geotextiles be used in the construction of landfills?

- Yes, geotextiles can be used in the construction of landfills. Geotextiles are often used as a barrier or separator material in landfill construction to help with soil erosion control, filtration, and drainage. They can also enhance the stability and overall performance of the landfill by preventing the mixing of different layers and providing reinforcement.

- Q: Can geotextiles be used in coastal protection?

- Yes, geotextiles can be used in coastal protection. Geotextiles are permeable fabrics made from synthetic materials that can effectively control erosion and stabilize soil in coastal areas. They can be used to reinforce coastal structures, such as breakwaters or revetments, to mitigate the impact of waves and currents, and to prevent sediment loss. Geotextiles also provide a barrier against weed growth and offer long-term durability, making them an efficient solution for coastal protection measures.

- Q: Can geotextiles be used in mining and landfill closure applications?

- Yes, geotextiles can be used in mining and landfill closure applications. Geotextiles are commonly used in these applications to provide erosion control, soil stabilization, and filtration. They act as a barrier to prevent soil erosion and help in containing mine waste or landfill materials. Additionally, geotextiles can improve the overall efficiency and safety of these operations by reducing the risk of environmental contamination.

- Q: Are geotextiles suitable for use in landfill applications?

- Yes, geotextiles are suitable for use in landfill applications. They are commonly used as a protective layer to separate different materials in landfills, providing filtration and drainage capabilities. Geotextiles help prevent the mixing of waste materials, facilitate leachate collection, and enhance overall stability and performance of landfills.

- Q: What are the factors to consider when selecting geotextiles for coastal protection projects?

- When selecting geotextiles for coastal protection projects, there are several factors to consider. Firstly, the type and quality of the geotextile material is crucial. It should be durable, resistant to UV radiation, and capable of withstanding the harsh coastal environment, including exposure to saltwater and strong waves. Secondly, the intended function of the geotextile should be taken into account. Different geotextiles offer varying levels of erosion control, filtration, and stabilization. Therefore, the specific needs of the coastal protection project, such as preventing beach erosion or stabilizing coastal structures, should be considered. Thirdly, the site conditions and project requirements play a significant role. Factors like wave energy, sediment characteristics, and slope stability need to be assessed to determine the appropriate geotextile specifications. Furthermore, the installation and maintenance requirements should be evaluated. Geotextiles that are easy to install and require minimal maintenance are often preferred, as they can save time and costs during the project's lifespan. Lastly, the cost-effectiveness and longevity of the geotextile should be taken into consideration. It is essential to balance the initial cost of the geotextile with its expected lifespan and performance to ensure a sustainable and economical solution for coastal protection.

- Q: What are the different geotextile installation techniques in filtration?

- Some of the different geotextile installation techniques in filtration include direct placement, wrap and trench, and sand bag placement. Direct placement involves placing the geotextile directly on the soil surface, while wrap and trench involves wrapping the geotextile around a soil layer or pipe and placing it in a trench. Sand bag placement involves constructing sand bags filled with soil and placing them against the geotextile to hold it in place. These techniques help to ensure proper filtration and prevent soil erosion.

- Q: Can geotextiles be used in retaining wall drainage systems?

- Yes, geotextiles can be used in retaining wall drainage systems. Geotextiles are commonly used as a filter to prevent soil erosion while allowing water to pass through. In retaining wall drainage systems, geotextiles can be installed behind the wall to prevent the clogging of drainage pipes and promote efficient water flow, reducing hydrostatic pressure and preventing damage to the wall.

- Q: Can geotextiles be used for erosion control in construction sites?

- Yes, geotextiles can be used for erosion control in construction sites. They are commonly employed to stabilize slopes, prevent soil erosion, and enhance drainage. Geotextiles act as a barrier, filtering out sediment and allowing water to pass through, thereby reducing the risk of erosion and maintaining the integrity of the construction site.

Send your message to us

Us200 Geotextile Steel Plastic Geogrids Biaxial for Civil Engineering Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords