Ring-lock scaffolding Accessories for formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

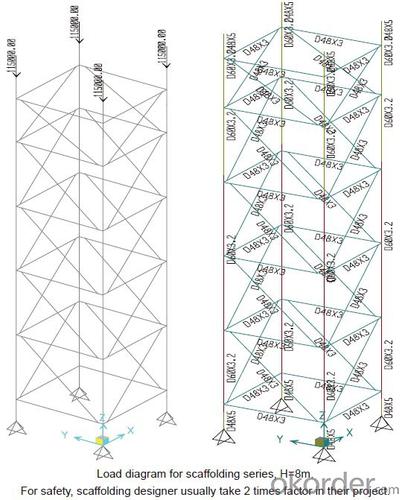

Ring-lock Scaffolding

A support system for construction, ownsadvantages of both cup-lock scaffolding andshoring tower.

It is in the development direction of new typescaffolding.

It is widely used in buildings, bridges, tunnels etc..

Characteristics:

◆ Easy to storage and transportation

◆ High degree of standardization

◆ Easy and quick erection

◆ Excellent stability and bearing capacity

- Q: How does steel formwork contribute to the overall cost of concrete construction?

- There are several ways in which steel formwork affects the overall cost of concrete construction. Firstly, the upfront cost of steel formwork may be higher compared to timber or plastic. However, the long-term durability and reusability of steel formwork can offset this initial expense over the lifespan of multiple construction projects. In addition, the use of steel formwork can significantly reduce the time needed for formwork assembly and dismantling. This leads to increased efficiency and productivity on the construction site, resulting in potential savings in terms of labor and project duration. Furthermore, steel formwork's superior strength and stability allow for the construction of larger and more complex structures. This can eliminate the need for additional support structures or reinforcements, ultimately reducing construction costs. Moreover, steel formwork provides a smooth and high-quality finish to the concrete structure, eliminating the need for additional plastering or finishing work. This not only saves on material costs but also reduces the overall construction time. Lastly, the reusability of steel formwork allows for multiple applications on different projects, providing long-term cost benefits. Unlike other formwork materials that may require frequent replacement, steel formwork can be used for multiple construction cycles, reducing the need for new formwork materials and saving costs in the long run. In conclusion, despite the higher initial investment, the durability, efficiency, superior strength, and reusability of steel formwork contribute to cost savings in terms of labor, project duration, material usage, and long-term formwork expenses.

- Q: What are the different edge protection systems available for steel formwork?

- Some of the different edge protection systems available for steel formwork include edge protectors, guardrails, safety nets, and toe boards.

- Q: How does steel formwork impact the overall sustainability of a project?

- Steel formwork has a significant impact on the overall sustainability of a project due to its durability, reusability, and recyclability. Unlike traditional timber formwork, steel formwork can be used multiple times, reducing waste generation and minimizing the need for new materials. Its robustness also ensures longer service life, reducing the frequency of replacements and associated carbon emissions. Additionally, steel formwork can be easily recycled at the end of its life, further reducing its environmental footprint. Overall, the use of steel formwork promotes resource efficiency, lowers construction costs, and contributes to a more sustainable construction industry.

- Q: What are the different types of coatings applied to steel formwork panels?

- There are several types of coatings that can be applied to steel formwork panels, including epoxy-based coatings, polyurethane coatings, zinc-rich coatings, and galvanized coatings. Each type of coating offers different levels of protection against corrosion, weathering, and chemical exposure, ensuring the durability and longevity of the steel formwork panels.

- Q: How does steel formwork affect the overall labor requirements of a construction project?

- Steel formwork can greatly impact the overall labor requirements of a construction project in several ways. Firstly, steel formwork is highly durable and robust, which means it can be reused multiple times. This reduces the need for labor-intensive tasks such as constantly constructing and dismantling formwork, resulting in significant time and cost savings. Moreover, steel formwork is much quicker to assemble and disassemble compared to traditional timber formwork. This increased efficiency allows construction projects to progress at a faster pace, reducing the overall duration of the project and minimizing labor requirements. Additionally, steel formwork offers greater dimensional accuracy and stability, resulting in fewer adjustments and modifications during the construction process. This reduces the need for labor-intensive rework and ensures that the project stays on schedule. Furthermore, steel formwork can be easily customized and fabricated to meet specific project requirements, which allows for faster and more precise construction. This reduces the need for manual alterations and adjustments, saving both time and labor. Lastly, steel formwork provides a safer working environment for laborers. Its sturdy structure and ability to withstand heavy loads enhance worker safety, reducing the risk of accidents and injuries. This not only ensures the well-being of the workforce but also minimizes potential delays and labor requirements caused by injuries. Overall, steel formwork can significantly reduce the labor requirements of a construction project by streamlining the construction process, enhancing efficiency, improving accuracy, and enhancing worker safety.

- Q: How does steel formwork affect the overall aesthetics of the structure?

- Steel formwork typically does not directly affect the overall aesthetics of a structure as it is used as a temporary mold to shape the concrete during construction. However, steel formwork can indirectly impact the aesthetics by facilitating precise and smooth concrete finishes, resulting in a more visually appealing final product.

- Q: How is steel formwork assembled?

- Steel formwork is assembled by first erecting vertical steel supports which are secured in place. Horizontal steel beams are then connected to the vertical supports to create a sturdy framework. Steel panels are then attached to the framework to form the desired shape of the concrete structure. Finally, the gaps and joints between the steel panels are sealed to ensure proper containment and support during the pouring of concrete.

- Q: How does steel formwork handle different concrete surface treatments?

- Steel formwork is highly versatile and can handle different concrete surface treatments effectively. The smooth and rigid nature of steel formwork allows for the application of various surface treatments, such as textured finishes, exposed aggregate, or decorative patterns, without compromising the quality or integrity of the concrete. Steel formwork provides a stable and durable framework that ensures the desired surface treatment remains intact during the concrete pouring and curing process. Furthermore, the reusability of steel formwork allows for consistent and reliable results across multiple projects with different concrete surface treatments.

- Q: What are the different types of supports used in steel formwork construction?

- There are several types of supports that are commonly used in steel formwork construction. These supports are designed to provide stability and structural integrity to the formwork system, ensuring that it can withstand the weight of the concrete during pouring and curing. One of the most common types of supports used in steel formwork construction is the adjustable steel prop. These props are made of adjustable steel tubes that can be extended or retracted to the desired height. They are typically used to support horizontal beams or slabs, and can be adjusted to accommodate different heights and angles. Another type of support used in steel formwork construction is the scaffolding system. Scaffolding consists of a series of metal frames and platforms that are erected to provide a temporary structure for workers to access the formwork. Scaffolding is often used in larger construction projects where multiple levels of formwork need to be supported. Additionally, steel beams and columns can also be used as supports in steel formwork construction. These structural elements are designed to bear heavy loads and provide stability to the formwork system. They are typically used in combination with other types of supports to create a strong and secure formwork structure. In some cases, hydraulic jacks may be used as supports in steel formwork construction. These jacks can be used to provide additional support and ensure that the formwork system remains stable during the pouring and curing process. Overall, the choice of supports in steel formwork construction will depend on the specific requirements of the project, including the size and weight of the formwork, the height and angle of the structure, and the availability of equipment and resources. It is important to carefully consider these factors and select the appropriate supports to ensure the safety and efficiency of the construction process.

- Q: What are the common problems encountered with steel formwork?

- Construction projects can encounter several common problems with steel formwork. One primary issue involves corrosion. When exposed to moisture or harsh environments, steel formwork is susceptible to rust and deterioration. This can compromise the structure's integrity, weakening it and creating potential safety hazards. Another problem arises from the heavy weight of steel formwork, making its handling and transportation difficult. This challenge is particularly evident on-site, especially in tight spaces or high-rise buildings. Moreover, the weight of the steel formwork increases labor and equipment costs required for installation. Additionally, regular maintenance is necessary to prevent damage and ensure the longevity of steel formwork. This maintenance involves cleaning, repairing any corrosion or dents, and applying protective coatings to prevent further deterioration. However, this maintenance can be both time-consuming and costly, contributing to the overall project expenses. Furthermore, steel formwork may not be suitable for certain construction applications. It lacks the easy customization and adjustability found in other formwork materials like timber or plastic. Consequently, its flexibility in accommodating unique shapes or designs is limited. Lastly, steel formwork generally incurs higher costs compared to other formwork materials. This financial aspect can impact the project budget, particularly for smaller or budget-constrained construction projects. To ensure a successful construction project, it is crucial to acknowledge these common problems and take necessary precautions. This involves regular maintenance, proper handling, and considering alternative formwork materials when appropriate. By addressing these issues, the durability and strength offered by steel formwork can be maximized.

Send your message to us

Ring-lock scaffolding Accessories for formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords