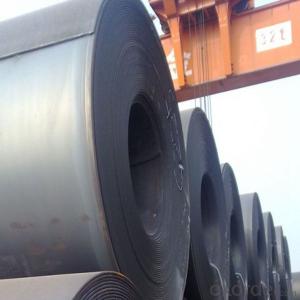

Steel Sheets Hot Rolled Steel Coils SS400 Good Quality

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 28 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

DESCRIPTION FOR SS400 CARBON STEEL SHEET

1.Thickness: 1-200mm

2.Width: 100-3000mm

3.Length: 1000-12000mm

4. Applications :mining machinery, environmental protection, engineering

5. Grade:SS400 A 36 Q195.Q235.Q345.SPCC.SPCH

6.Surface : Hot Rolled Cold Rolled Galvanized Steel

DESCRIPTION:

GRADE: SS400, ASTM A36, A572, ST37,ST52, Q195, Q215, Q235,Q345, S235JR etc.

STANDARD: GB/T709-2006, ASTM A36, JIS G3101, DIN EN 10025, SAE 1045, ASTM A570

SPEC:

1)Width: 600-2500mm or 1000,1050,1250,1500,1800,2000mm

2)Thickness:1.5mm-200mm or as customers’ special requirements;

3)Length: 2-12m or as customers’ special requirements

DETAILS:

Thickness | 0.5-100mm |

Width | 1250mm,1500mm,1800mm,2000mm.,2500mm or as required |

Length | 2000-12000mm |

Standard | AISI, ASTM, BS, DIN, GB, JIS |

Material | A36,SS400,SPCC,SPHC, Q195, Q 235,Q345 |

Tehnique | Hot rolled;cold rolled |

Payment | TT ,L/C |

Packing | Standard seaworthy packing or as required |

Market | Mild east, North/South America, Europe, Asia,Africa etc |

Certificate | BV,SGS,MTC |

Delivery time | 30-45days after confirming the order |

PACKING:

1.Big thickness:by bulk vessel

2.Small thickness:packed by steel strips and shipped by container

3.According to the requirements of customers'

TRADE TERMS :FOB, CFR, CIF

DETAILED PICTURES FOR STEEL COILS

PAYMENT&DELIVERY FOR STEEL COILS/SHEETS

Payment Terms | 100% LC at sight,or 30%TT in advance, balance against B/L copy |

Delivery Time | With 30-40 days after deposit |

Price Terms | Ex-Work, FOB, CNF, CFR, CIF,etc |

FAQ

Q:What are the advantages of your company ?

A: We have many professionals, technical personnel, more competitive prices and best after-dales service than other steel companies.

Q:Can you arrange the shipment ?

A: Sure we can help you with the shipment. We have forwarders who have cooperated with us for many years.

- Q: What are the insulation properties of steel sheets?

- Compared to other commonly used insulation materials like fiberglass or foam, steel sheets have relatively poor insulation properties. This is because steel is an excellent conductor of heat and electricity, possessing high thermal conductivity. Consequently, steel sheets are ineffective in preventing heat transfer and are not typically used as standalone insulation materials. Nonetheless, steel sheets can still offer some insulation benefits when utilized alongside other insulating materials. For example, they can serve as a protective layer or cladding, enhancing the durability and fire resistance of insulation systems. Additionally, they can function as a radiant barrier, redirecting heat away from buildings and reducing heat gain in warm climates. To summarize, although steel sheets themselves do not possess exceptional insulation properties, they can contribute to improving overall insulation performance when combined with other insulating materials or applied in specific scenarios such as radiant barriers.

- Q: Can steel sheets be used for elevator shafts?

- Yes, steel sheets can be used for elevator shafts. Steel is a widely used material for constructing elevator shafts due to its durability, strength, and fire-resistant properties. Steel sheets are commonly used to create the walls and floors of elevator shafts, providing structural support and ensuring the safety of the elevator system. They can be easily fabricated, allowing for precise customization to fit the specific dimensions and design requirements of the elevator shaft. Additionally, steel sheets can be treated with various coatings to prevent corrosion and enhance their longevity. Therefore, steel sheets are a suitable choice for constructing elevator shafts, offering a reliable and robust solution for vertical transportation systems.

- Q: Can steel sheets be formed into cylinders or tubes?

- Yes, steel sheets can be formed into cylinders or tubes through a process called sheet metal rolling or tube forming.

- Q: How can the offset film affixed to the cold-rolled steel sheet be removed?

- Hand cream can also be achieved to remove the effect of self-adhesive, hand cream contains a lot of water (generally more than 70%), water contains a certain amount of surfactant. Surfactant has good wetting, permeating and dissolving ability. It can quickly penetrate between the adhesive and the surface of the object, so as to achieve the goal of cleaning. You can also find some similar products, such as creams, facial cleanser and detergent.

- Q: What is the difference between zinc-coated and zinc-aluminum coated steel sheets?

- Zinc-coated steel sheets are made by applying a layer of pure zinc onto the surface of the steel through a process called galvanization. On the other hand, zinc-aluminum coated steel sheets are created by combining zinc and aluminum in a specific ratio before applying it to the steel surface. The addition of aluminum enhances the corrosion resistance and durability of the coating compared to pure zinc-coated sheets.

- Q: Can the steel sheets be used for elevator doors?

- Indeed, elevator doors can utilize steel sheets. Given steel's robustness, longevity, and fire-resistant attributes, it serves as a prevalent choice for constructing elevator doors. By manipulating and tailoring steel sheets, they can be customized to precisely match the dimensions and specifications of the elevator doors, ensuring a dependable and secure enclosure. Moreover, steel sheets can be treated with diverse coatings and finishes to augment their aesthetic appeal while safeguarding them against corrosion.

- Q: What are the common sizes and thicknesses of steel sheets?

- The common sizes of steel sheets typically range from 4 feet by 8 feet (1.2 meters by 2.4 meters) to 5 feet by 10 feet (1.5 meters by 3 meters). As for thicknesses, they can vary from 16 gauge (0.0598 inches or 1.52 millimeters) to 10 gauge (0.1345 inches or 3.42 millimeters). However, it's important to note that there are numerous other sizes and thicknesses available depending on specific applications and requirements.

- Q: What are the dimensions of steel sheets?

- The dimensions of steel sheets vary depending on the specific application and manufacturer. However, steel sheets typically come in standard sizes ranging from 4 feet by 8 feet (1.2 meters by 2.4 meters) to 6 feet by 10 feet (1.8 meters by 3 meters). Additionally, thicknesses can range from 0.015 inches (0.4 millimeters) to over 1 inch (25 millimeters), again depending on the intended use.

- Q: What are the environmental impacts of steel sheet production?

- The environmental impacts of steel sheet production include carbon emissions from the burning of fossil fuels during the manufacturing process, the consumption of large amounts of energy and water, and the generation of waste and pollutants such as particulate matter, sulfur dioxide, and nitrogen oxides. Additionally, the extraction of raw materials for steel production, such as iron ore and coal, can lead to deforestation, habitat destruction, and soil erosion.

- Q: What's the difference between steel plate 20 and Q235 steel plate?

- In the normalizing state of No. 20 steel, the yield point is 245MPa, the elongation is >25%, the quenched and tempered state, the yield point is 280MPa, and the elongation is >22%. Widely used in the production of small, high load toughness requirements of parts, such as rod, heavy and general machinery in forging the sleeve, fixture and liner, general machinery and automobiles and tractors in small parts of carburizing, cyaniding.

Send your message to us

Steel Sheets Hot Rolled Steel Coils SS400 Good Quality

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 28 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords