Hot Rolled Steel Billet Q235 Q275 Q345 for Ceramic Tunnel Kiln

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot Rolled Steel Billet Q235 Q275 Q345 for Ceramic Tunnel Kiln

Description

Reference Price:$260/ton Mn 0.3%-0.6%

Rectangular billet continuous casting billet and mainly general carbon steel, low carbon low silicon cold-rolled material, high quality carbon structural steel, high strength low alloy steel, special steel, etc.

The billet is mainly divided into two kinds from the shape:

Slab: cross section width and height of the ratio of the larger, mainly used for rolling plate.

Billet: equal cross section width and height, or a huge difference, mainly used for rolling steel, wire rod. ,

Steel billets have distinct characteristics as compared with already furnished steel bars and products. Billets have a specific grain structure, which enables the metal to be processed more intricately. Steel billets are also known for their malleability and ductility, especially when exposed to varying temperatures during shaping and molding.

Processing of Steel Billet

Steel billets are considered fresh and raw, and they must undergo a series of manufacturing processes before they can be used for various purposes. Billets are made by means of freezing molten liquid, and are later exposed to extremely low temperatures in order to allow the metal to take shape and solidify in chemical structure. The temperature manipulates the metal's physical properties, and tones its strength and durability. The subsequent processes provide the metal's curved mold design so that it can fit the allotted space provided by other machines, which complete the finishing procedures.

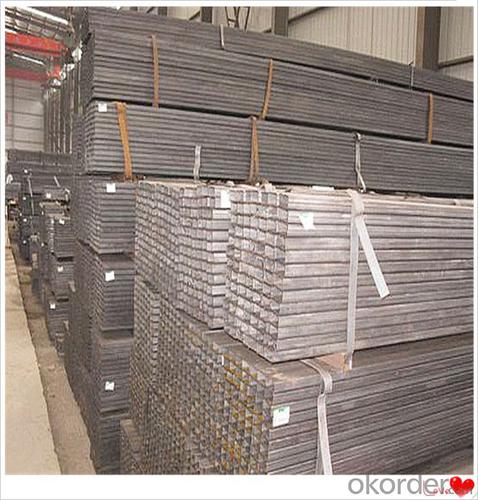

Images

Technical Data

Size:100*100,120*120,150*150,130*130

Mn: 0.3%-0.6%

C: 1%

Cr:0.1%

Packaging

cargo ship or container

usually container price will add 15USD per ton

RFQ

We have organized several common questions for our clients,may help you sincerely:

1) How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2) How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3) How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

4)Do you have your own QC department?

Yes, we have, our QC department will inspect the goods during the process of mass production and after completion of production.

hot sale!!! steel billets/ mild steel bar/ billet steel

(1): High quality steel with reasonable price.

(2): Wide excellent experiences with after-sale service.

(3): Every process will be checked by responsible QC which insures every product's quality.

(4): Professional packing teams which keep every packing safely.

(5): Trial order can be done in one week.

(6): Samples can be provided as your requirements.

If you are interested in our products, please don't hesitate to contact me.

Your any inquiry will be appreciated and we will offer you a rock-bottom price.

- Q: How are steel billets used in the manufacturing of storage tanks?

- Steel billets serve as the primary raw material in the manufacturing of storage tanks. These semi-finished metal forms act as the starting point for producing steel plates or sheets, which are later used to construct the tank walls and base. Once obtained, the steel billets undergo heating and are then passed through a series of rollers to gradually shape them into the desired form. This process, known as hot rolling, is essential for creating the necessary thickness and dimensions required for the storage tank. Following the hot rolling process, the steel billets undergo further processing to eliminate any surface impurities or imperfections using a technique called descaling. This step guarantees the quality and durability of the final tank structure. Next, the steel billets are cut into smaller pieces, referred to as plates or sheets, which are then shaped and welded together to form the tank shell. These plates are meticulously cut and shaped according to specific engineering drawings and designs, ensuring that the tank meets the required specifications for strength, capacity, and structural integrity. Apart from the tank shell, steel billets are also used in manufacturing the tank's base or floor. The billets are processed and formed into the required shape, which is then welded or bolted to the tank shell to create a solid foundation for the storage tank. In conclusion, steel billets play a crucial role in the manufacturing of storage tanks by providing the necessary raw material for building the tank structure. Through various processes, the billets are transformed into steel plates and sheets, which are then shaped into the tank shell and base, ensuring the tank's strength and durability.

- Q: How are steel billets cast into shape?

- Steel billets are cast into shape using a process called continuous casting. This process involves pouring molten steel into a water-cooled copper mold, which is in the shape of a billet. As the steel is poured, it begins to solidify along the walls of the mold. At the bottom of the mold, a water spray is used to rapidly cool the steel, causing it to solidify completely. As the steel solidifies, it is continuously pulled out of the mold by a set of rollers or by a chain conveyor. Once the billet is completely solidified, it is cut into desired lengths using a high-speed torch or saw. These cut billets are then transported to the next stage of the steel manufacturing process, such as rolling or forging, where they are further shaped into the final desired product. Continuous casting allows for the production of steel billets with a consistent cross-sectional shape and size. This process is highly efficient and produces high-quality steel products with minimal waste.

- Q: What are the main differences between hot rolled and cold rolled steel billets?

- The main differences between hot rolled and cold rolled steel billets lie in the manufacturing process and the resulting properties of the finished product. Hot rolled steel billets are produced by heating the steel to a high temperature and then rolling it through large rollers. This process allows for the steel to be shaped and formed easily, resulting in a product with a rougher surface and less precise dimensions. Hot rolled steel billets also tend to have a scaled surface due to the high temperature involved in the manufacturing process. On the other hand, cold rolled steel billets are produced by cooling the steel to room temperature and then passing it through rollers at a lower temperature. This process not only results in a smoother surface finish but also allows for tighter tolerances and more precise dimensions. Cold rolled steel billets have a more uniform appearance and are often used in applications that require a higher degree of precision and accuracy. In terms of mechanical properties, hot rolled steel billets generally have a lower strength and hardness compared to cold rolled steel billets. Cold rolled steel billets also tend to have improved surface hardness and a higher degree of dimensional stability. Overall, the main differences between hot rolled and cold rolled steel billets are the manufacturing process, surface finish, dimensional accuracy, and mechanical properties. Hot rolled steel billets are more easily shaped and formed, while cold rolled steel billets have a smoother surface finish and more precise dimensions. The choice between the two depends on the specific requirements of the application.

- Q: How do steel billets contribute to the manufacturing of sports gear?

- Steel billets play a crucial role in the manufacturing of sports gear. These cylindrical or square-shaped semi-finished products are made by casting liquid steel into molds and then allowing them to solidify. Once the steel billets are formed, they can be further processed to create various sports equipment such as golf clubs, tennis rackets, baseball bats, and hockey sticks. One of the main reasons steel billets are used in the production of sports gear is due to their exceptional strength and durability. Steel is known for its high tensile strength, which means it can withstand significant amounts of force without breaking or deforming. This makes it an ideal material for sports equipment that requires resilience and longevity. Furthermore, steel billets offer excellent flexibility and customization options in terms of design and performance. Manufacturers can shape and mold the billets to create different types of sports gear, implementing specific features that enhance performance. For example, golf club heads are often made from steel billets, allowing manufacturers to manipulate the weight distribution to optimize the swing dynamics and increase distance. Steel billets also contribute to the performance of sports gear by providing stability and control. The rigid nature of steel ensures that the equipment maintains its shape and does not experience excessive vibrations during use. This stability is particularly crucial in sports like tennis or hockey, where precise control and accuracy are paramount. Moreover, steel billets can be combined with other materials to create composite sports gear. By integrating steel with materials like carbon fiber or titanium, manufacturers can create lightweight yet incredibly strong equipment. This combination allows for improved maneuverability and better overall performance. In summary, steel billets are vital components in the manufacturing of sports gear due to their exceptional strength, durability, flexibility, and customization options. From golf clubs to hockey sticks, steel billets contribute to the production of high-quality sports equipment that offers stability, control, and enhanced performance for athletes.

- Q: What is the role of steel billets in the manufacturing of conveyor belts?

- The manufacturing process of conveyor belts heavily relies on steel billets, which are essential in creating the various components of the belt. These billets, derived from molten steel, serve as the initial stage in production. To begin, the steel billets undergo heating and rolling processes to form thin sheets or strips, depending on the desired thickness of the conveyor belt. These sheets are then further processed to construct the core structure of the belt, providing the necessary strength and durability to withstand demanding conditions. Moreover, steel billets play a crucial role in producing the metal reinforcements within the belt. These reinforcements, typically in the form of steel cords or wires, are embedded into the belt to enhance its tensile strength, preventing stretching or breaking under heavy loads and ensuring longevity and reliability. Additionally, steel billets are utilized in manufacturing the pulley system of the belt. Pulleys are essential components that facilitate the movement of materials along the belt. Made from solid steel billets, these pulleys are machined and designed to smoothly guide the belt while maintaining proper tension. In conclusion, steel billets serve as the foundation for creating the core structure, reinforcements, and pulleys of conveyor belts. Their strength and versatility make them an ideal material for producing belts that can withstand the rigorous conditions of industrial applications, guaranteeing efficient and reliable material handling processes.

- Q: What are the different types of casting processes used for shaping steel billets?

- There are several types of casting processes used for shaping steel billets. Some of the common ones include continuous casting, ingot casting, and centrifugal casting. Continuous casting involves pouring molten steel into water-cooled molds to create a continuous strand of solidified steel. Ingot casting involves pouring molten steel into individual molds to create solidified ingots. Centrifugal casting utilizes centrifugal force to pour molten steel into a rotating mold, resulting in a cylindrical shape. These casting processes offer different advantages and are used depending on the specific requirements of the steel billet shaping process.

- Q: Who knows the diamond is?Who knows the diamond is carbon? Is it C60?

- It is also called the diamond diamond, crystal, it is not the molecules themselves, so the formula does not apply to.C said it is only by this kind of carbon elements. While C60 is footballene is another matter, the 60 is because it is a molecular crystal, each molecule consists of 60 carbon.

- Q: Can steel billets be used in the production of pipes?

- Yes, steel billets can be used in the production of pipes. Steel billets are semi-finished metal products that can be further processed into various shapes, including pipes. The billets are heated, pierced, and elongated to form seamless pipes or rolled and welded to create welded pipes.

- Q: How do steel billets contribute to the automotive industry?

- The automotive industry heavily relies on steel billets as the primary raw material for manufacturing different automotive components. These components, including engine parts, transmission systems, chassis, suspension systems, and other critical parts, are crucial for ensuring the safety, performance, and durability of vehicles. A significant contribution of steel billets to the automotive industry lies in their exceptional strength and durability. Steel is widely known for its high tensile strength, which enables it to withstand extreme forces and provide structural integrity to automotive components. This strength is particularly crucial in areas such as the frame, where it ensures passenger safety in the event of a collision. Moreover, steel billets offer excellent formability and versatility, allowing manufacturers to create intricate and complex automotive parts with precision. This enables the production of components that meet the specific design requirements of different vehicle models, ensuring optimal performance and functionality. Another advantage of steel billets is their cost-effectiveness. Compared to alternatives like aluminum or carbon fiber, steel is a relatively affordable material. Its widespread availability and production efficiency make it an economical choice for mass production, helping to keep vehicle prices reasonable for consumers. Furthermore, steel billets possess excellent heat resistance and thermal conductivity properties, making them ideal for use in engine components, such as pistons and cylinder heads. They can withstand high temperatures and efficiently transfer heat. Additionally, steel billets contribute to the sustainability of the automotive industry. Steel is highly recyclable, with a recycling rate of around 90%. This allows for the eco-friendly disposal and reuse of steel components, reducing the environmental impact of the automotive manufacturing process. In conclusion, steel billets play a crucial role in the automotive industry by providing the necessary strength, durability, formability, and cost-effectiveness for manufacturing various automotive components. Their versatility and recyclability further contribute to the sustainability of the industry. Without steel billets, the automotive industry would face challenges in producing safe, reliable, and affordable vehicles.

- Q: What are the main challenges in the handling of steel billets during production?

- The handling of steel billets during production presents several challenges that need to be overcome for a smooth and efficient manufacturing process. One of the main challenges is the weight and size of the steel billets. Steel billets can be quite heavy, ranging from a few hundred kilograms to several tons, depending on their dimensions. This poses difficulties in terms of lifting and moving them within the production facility. Specialized equipment such as cranes and forklifts are required to handle these heavy loads safely. Another challenge is the potential for damage to the steel billets during handling. Steel billets are typically transported and stored in stacks or bundles. Improper handling techniques or insufficient protection can lead to deformation, scratches, or even breakage of the billets. These damages can affect the quality of the final product, leading to increased scrap rates and production costs. Additionally, maintaining precise temperature control is crucial during the handling of steel billets. Steel is sensitive to temperature changes, and the billets need to be kept within specific temperature ranges to avoid distortion or metallurgical issues. Special care must be taken when transferring billets between different areas of the production facility to ensure temperature consistency. Ensuring proper inventory management and tracking is also a challenge in billet handling. Steel billets are often stored in large warehouses or outdoor yards, and keeping track of their location, quantity, and quality can be complex. Efficient inventory management systems, such as barcoding or RFID tagging, are essential to minimize errors and efficiently retrieve the required billets for production. Lastly, safety is a significant concern when handling steel billets. The weight and potential for injury make it vital to follow strict safety protocols. Operators need to be properly trained on the use of equipment, such as cranes and forklifts, and wear appropriate personal protective equipment (PPE) to prevent accidents or injuries. Overall, the main challenges in the handling of steel billets during production revolve around their weight, potential for damage, temperature control, inventory management, and safety. Overcoming these challenges requires investments in specialized equipment, training, and efficient processes to ensure a smooth and successful production operation.

Send your message to us

Hot Rolled Steel Billet Q235 Q275 Q345 for Ceramic Tunnel Kiln

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords