Woven Geotextile Fabric Prices - Staple Fiber Needle Punched Geotextile (2-6m)

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description Of Staple Fiber Needle Punched Geotextile:

Filament yarn with polyester filament geotextile acupuncture non-woven geotextile, there is a polyester filament

geotextile after high-speed needle acupuncture and into cloth products, do not contain chemical additives in the

process of needle, also without heat treatment, is environmentally friendly building materials.Can replace the

traditional engineering materials and construction methods, construction is more secure, and contribute to

environmental protection, can be more economic, effective and lasting to solve basic problems in engineering

construction.

Main Features of Staple Fiber Needle Punched Geotextile:

1, tensile and tearing resistance, bursting resistance, resistance to puncture, such as high mechanical strength, is equally grams weighs more than doubling of staple fiber geotextile, especially bursting resistance, strength reached more than 2200 Newton, in the stone slope protection, can effectively prevent irregular stones on the impact of the cloth;

2, good extension performance, stress dispersion and transmission is fast, make the uniformly distributed load;

3, the friction coefficient is big, not easy to slip when construction;

4, good chemical resistance;

5, corrosion resistance;

6, ageing resistance, embedded laid, the service life of more than 50 years;

7, heat resistant, cold resistant performance is good, can withstand 200 ~ 30 ℃ temperature difference and the quality is not affected;

Specifications of Staple Fiber Needle Punched Geotextile:

1.woven geotextile(reinforced geotextile)

2.Materials:PP

3.Tensile strength:15~100kn/m

4.Unit weight:100~400g/m2

5.Width:1 ~ 6m

| Packaging | packed in roll or as the customer's requirements |

| Delivery | 10 days after get the deposit |

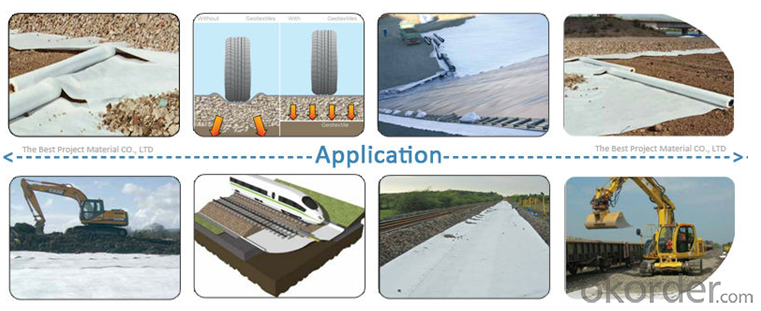

Applications of Staple Fiber Needle Punched Geotextile:

1.Seperation of different material:applied between subgrade and groundwork of the paved(un-paved) roador airport road.Applied between the subgrade and ballast of the railway,applied in the landfill ground and gravelsubgrad,applied between the geomembrane and sandy drainage layer,applied between the subgrade and ground work to undertake the additional load.Applied between the earth of groundwork and foundation soil,applied under footpath,parking lot,stadium,applied between the new and old asphalt.

2.Reinforcement of the soft foundation:applied on the soft foundation of the unpaved road,the airport path,railroad,the landfill,the stadium,etc prevent the geomembrane to be punctured by the gavel.

3.Filtration:applied at the bottom of the lanfill that penetrate,to protect the geonet and geocomposite and prevent the soil to enter inside.

4.Drainage:applied under the geomembrane,the stadium,the ballast of the railway.

IMages of Staple Fiber Needle Punched Geotextile:

FAQ:

1. Do you supply free samples for customers?

Yes,we will supply free samples for you.Please send your address for us.

2. How Many years experience do you have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: How do geotextiles affect wildlife habitats?

- Geotextiles can have both positive and negative impacts on wildlife habitats. On one hand, they can enhance and protect habitats by stabilizing soil, reducing erosion, and preventing sedimentation in water bodies. This can benefit various species by preserving their natural habitats and reducing the risk of habitat degradation. On the other hand, improper installation or use of geotextiles can disrupt or alter wildlife habitats, creating barriers to movement, limiting access to resources, or affecting nesting and breeding areas. Therefore, it is crucial to consider the environmental impacts and carefully plan the implementation of geotextiles to minimize any negative effects on wildlife habitats.

- Q: Can geotextiles be used for reinforcement in asphalt overlays?

- Yes, geotextiles can be used for reinforcement in asphalt overlays. Geotextiles act as a separator and provide reinforcement by distributing stress and preventing the mixing of different layers. They help in reducing reflective cracking and increasing the lifespan of the asphalt overlay.

- Q: How do geotextiles help with soil stabilization in steep slopes?

- Geotextiles help with soil stabilization in steep slopes by providing reinforcement and preventing erosion. When placed on the slope, geotextiles act as a barrier, holding the soil in place and preventing it from sliding or eroding downhill. The geotextiles also allow water to pass through while retaining the soil, reducing the impact of heavy rainfall or water flow on the slope. This helps to maintain the integrity of the slope, preventing landslides and ensuring long-term stability.

- Q: 300 grams of geotextile how much money a square meter

- Geotextile, also known as geotextile, it is made of synthetic fiber through acupuncture or woven from the permeability of geosynthetics. Geotextile is a new material geosynthetics which one, the finished product for the cloth, the general width of 4-6 meters, the length of 50-100 meters. Geotextile is divided into a spinning geotextile and non-woven filament geotextile. Ordinary about 2.00 friends

- Q: Can geotextiles be recycled?

- Yes, geotextiles can be recycled. They are typically made from synthetic materials such as polypropylene or polyester, which can be melted down and reused to create new geotextile products. Recycling geotextiles helps reduce waste and promotes sustainability in the construction and environmental industries.

- Q: River slope protection geotextile unit area quality is generally how much

- Under normal circumstances is 100g - 1000g / square meter of the specifications, the actual situation is subject to special requirements, usually available geotextile unit area quality tester for testing, reference [standard group]. Test criteria: ASTM / D3776 / 2646, ISO3801, BS3424 / 2471, BSEN, M + SP65 / 65A, NEXT20

- Q: Engineering geotextile non-woven fabrics where the cheapest can buy, where the wholesale market?

- Manufacturers need to add 8720 -

- Q: What are the experiments required for earthwork dam geotextiles

- The first thing to do is the "unit area quality" and "thickness", followed by "breaking strength", breaking elongation "," CBR broken strength ", and tear strength. Huazhi geotextile for your answer

- Q: Health geotextile how much money ah?

- Health geotextile, also known as geotextile, it is made of synthetic fibers through the needle or woven from the permeability of geosynthetics. Finished cloth for the cloth, the general width of 4-6 meters, the length of 50-100 meters. The price according to the weight and standard to set, weight (80-1500g / ㎡), the quality standard is a requirement, divided into non-standard, whitening A, Sinochem, the general national standard, Paul national standard, Wait. Ton price is generally between 4900-7500 yuan / ton, but the weight <200g, an increase of 100 yuan / ton; weight> 800g, an increase of 500 yuan / ton. 187 & lt; 6600 & lt; 5604

- Q: How do geotextiles help in preventing soil erosion in agricultural fields?

- Geotextiles help in preventing soil erosion in agricultural fields by acting as a barrier between the soil and external forces such as wind and water. They stabilize the soil by reducing surface runoff, preventing sedimentation, and promoting the growth of vegetation. Geotextiles also enhance filtration and drainage, allowing water to flow through while retaining soil particles, thus minimizing the risk of erosion.

Send your message to us

Woven Geotextile Fabric Prices - Staple Fiber Needle Punched Geotextile (2-6m)

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords