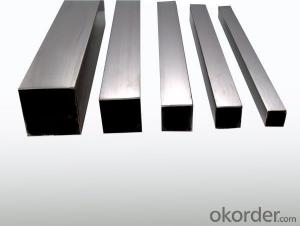

Stainless steel tube ; square tube

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Standard: | JIS,AISI,ASTM,GB | Place of Origin: | China (Mainland) | Model Number: | 304 316L 310S |

| Type: | Welded | Steel Grade: | 200 series,300 series,900 series | Application: | light industry,heavy industry,daily necessities and the decoration ind |

| Certification: | SGS | Thickness: | 0.3-100mm | Outer Diameter: | 6-1000mm |

| Item: | stainless steel square tube/pipe | Cetification: | SGS | Welding Line type: | welded |

| Quality: | High quality tube stainless steel | Package: | In plastic wrapper/wooden case/according to your requirements | Delivery: | In 15 days |

| Stock: | Available |

Packaging & Delivery

| Packaging Detail: | In plastic wrapper/wooden case/according to your requirements |

| Delivery Detail: | In 15 days |

Specifications

stainless steel square tube/pipe

T :o.3-100mm

OD:6-1000mm

Finish: bright

Quality: Top quality tube stainless steel

stainless steel square tube/pipe

Thickness:1-100mm

Outer Diameter:10-1000mm

Welding line type: ERW

Item | High quality stainless steel tube price |

Standard | ASTM A240,GB/T3280-2007,JIS4304-2005,ASTM A167,EN10088-2-2005,etc |

Material | 310S,310,309,309S,316,316L,316Ti,317,317L,321,321H,347,347H,304,304L 302,301,201,202,403,405,409,409L,410,410S,420,430,631,904L,Duplex,etc |

Thickness | 1-100mm |

Outer Diameter | Customized |

Welding line type | welded or seamless |

Package | Standard export package, suit for all kinds of transportation, or as required. |

Price term | Ex-Work, FOB, CNF, CFR, CIF, FCA, DDP, DDU, etc |

Payment term | T/T,L/C,DP,Western union |

MOQ | 500Kg |

Application | Stainless steel tube applies to construction field, ships building industry, Stainless steel tube can be made according to the customers’ requirements. |

Contact | If you have any question, please feel free to contact us. We believe customers first! |

- Q: What is the difference between annealed and pickled stainless steel pipes?

- Annealed stainless steel pipes and pickled stainless steel pipes both undergo different processes that affect their properties and appearance. Annealing is a heat treatment process that involves heating the stainless steel pipes to a specific temperature and then slowly cooling them. This process helps to relieve internal stresses and improve the ductility and toughness of the material. Annealed stainless steel pipes are usually softer and more malleable, making them easier to work with during fabrication and installation. They also tend to have a smoother, more polished surface finish. On the other hand, pickling is a chemical process that removes surface impurities such as oxides, scales, and rust from stainless steel pipes. It involves immersing the pipes in an acid solution, typically a mixture of nitric and hydrofluoric acid, which dissolves the impurities. Pickling helps to restore the corrosion resistance of the stainless steel and leaves a clean, bright, and uniform surface finish. In summary, the main difference between annealed and pickled stainless steel pipes lies in the processes they undergo. Annealing improves the material's ductility and toughness, while pickling removes surface impurities and restores corrosion resistance. The choice between annealed and pickled stainless steel pipes depends on the specific requirements of the application, such as the desired mechanical properties and surface finish.

- Q: What are the different types of stainless steel pipe gaskets?

- There are several types of stainless steel pipe gaskets available, including ring gaskets, spiral wound gaskets, and sheet gaskets.

- Q: Are stainless steel pipes suitable for cryogenic applications?

- Stainless steel pipes are indeed suitable for cryogenic applications due to their exceptional low-temperature properties. This material proves to be an ideal choice when dealing with extremely cold temperatures in cryogenic applications. Its impressive strength, outstanding resistance to corrosion, and commendable thermal conductivity are all crucial factors when handling cryogenic fluids or gases. The structural integrity and durability of stainless steel pipes remain intact even under the harshest cold conditions, avoiding any brittleness. Moreover, the ability of stainless steel to resist expansion and contraction ensures consistent and dependable performance in cryogenic environments. Hence, it is no wonder that stainless steel pipes have gained popularity in various industries like aerospace, medical, and energy where cryogenic applications are commonly encountered.

- Q: What is the maximum temperature limit for stainless steel pipes?

- The maximum temperature limit for stainless steel pipes varies depending on the grade of stainless steel used. However, in general, stainless steel pipes can withstand temperatures up to 1600°F (871°C) before experiencing significant deformation or loss of strength.

- Q: What is the difference between Sch 40 and Sch 80 stainless steel pipes?

- The main difference between Sch 40 and Sch 80 stainless steel pipes lies in their thickness. Sch 40 pipes have a thinner wall thickness compared to Sch 80 pipes, which means they have a lower pressure rating. On the other hand, Sch 80 pipes have a thicker wall thickness, making them suitable for higher pressure applications.

- Q: Can stainless steel pipes be used for breweries?

- Indeed, stainless steel pipes find widespread application in breweries. The brewing industry favors stainless steel as the prime material for brewing equipment and piping systems owing to its outstanding resistance to corrosion, remarkable durability, and hygienic attributes. Stainless steel pipes exhibit remarkable resilience in the face of harsh and acidic conditions commonly encountered in breweries, such as elevated temperatures, alkaline and acidic cleansing agents, as well as exposure to diverse chemicals. Moreover, the simplicity in cleaning and maintenance of stainless steel pipes guarantees the production of untainted and superior quality beer. In essence, the employment of stainless steel pipes in breweries serves to ensure a brewing process that is both safe and efficient.

- Q: Can stainless steel pipes be used in the mining industry?

- Yes, stainless steel pipes can be used in the mining industry. Stainless steel is a highly durable and corrosion-resistant material that is well-suited for the harsh and demanding conditions often found in mining operations. The mining industry involves the extraction and processing of various minerals and ores, which often require the use of corrosive chemicals and high-pressure fluids. Stainless steel pipes are able to withstand these harsh conditions and provide reliable and long-lasting performance. One of the main advantages of stainless steel pipes in the mining industry is their resistance to corrosion. The mining environment often contains corrosive substances such as saltwater, acids, and various chemicals used in the extraction and processing of minerals. Stainless steel pipes are resistant to these corrosive elements, ensuring that they do not degrade or weaken over time. This makes them ideal for transporting fluids and gases in mining operations. In addition to their corrosion resistance, stainless steel pipes also offer excellent strength and durability. They can withstand high pressures and temperatures, making them suitable for handling the demanding conditions of the mining industry. Stainless steel pipes are also known for their low maintenance requirements, which is crucial in remote mining areas where accessibility and maintenance can be challenging. Furthermore, stainless steel pipes are versatile and can be used in various applications within the mining industry. They can be used for transporting water, slurry, and other fluids, as well as for ventilation systems, structural components, and even for lining mine shafts. Their versatility and durability make them a cost-effective choice for mining companies, as they can be used in a wide range of applications and have a long service life. Overall, stainless steel pipes are a reliable and durable choice for the mining industry. Their resistance to corrosion, high strength, and versatility make them well-suited for the challenging conditions found in mining operations. By using stainless steel pipes, mining companies can ensure the efficient and safe transportation of fluids and gases, contributing to the success and productivity of their operations.

- Q: Can stainless steel pipes be cold worked?

- Yes, stainless steel pipes can be cold worked. Cold working is a process in which the metal is deformed at room temperature, typically through processes like bending, drawing, or rolling. Stainless steel's excellent mechanical properties and ductility make it well-suited for cold working, allowing for the creation of complex shapes and designs while retaining its strength and corrosion resistance.

- Q: Difference between stainless steel and steel pipe

- 2. welded steel pipe for different welding process and divided into the furnace pipe welding (ERW) pipe and automatic arc welding, because of the different forms of welding seam welded pipe and spiral welded pipe is divided into two kinds, end its shape is divided into circular welded and shaped (square, flat) pipe.The welded pipe is rolled into the steel tubular to sew or spiral seam welded in the manufacturing method, and is divided into low pressure fluid delivery with welded steel pipe, spiral welded steel pipe, welded steel pipe, welded pipe roll etc.. Seamless steel pipe can be used in various industries, such as liquid, pneumatic, pipeline and gas pipeline. Welding pipes can be used in water pipelines, gas pipelines, heating pipes, electrical appliances, pipelines and so on.

- Q: Can stainless steel pipes be insulated with polyurethane?

- Yes, stainless steel pipes can be insulated with polyurethane. Polyurethane insulation is a common choice for insulating pipes due to its excellent thermal properties and ability to adhere to various surfaces, including stainless steel. It helps to prevent heat loss or gain in the pipes, providing energy efficiency and protection against condensation.

Send your message to us

Stainless steel tube ; square tube

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords