Stainless Steel Sheet AISI 304

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 Ton m.t.

- Supply Capability:

- 5000ton m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

AISI 304 Stainless steel sheet

1. Chemical composition of Stainless steel sheet

C | Si | Mn | P | S | Ni | Cr |

max0.08 | max1.00 | max2.00 | max0.045 | max0.03 | 8.00-10.50 | 18.00-20.00 |

2. Mechanical properties of Stainless steel sheet

Yield Strength | Tensile | Elongation | Hardness (HV) | Hardness (HRB) |

≥ 205 | ≥ 520 | ≥ 40 | ≤ 200 | ≤ 90 |

3. Standard of Stainless steel sheet : AISI, ASTM, GB, EN, DIN, JIS

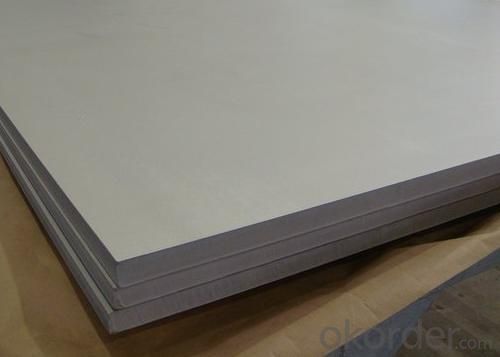

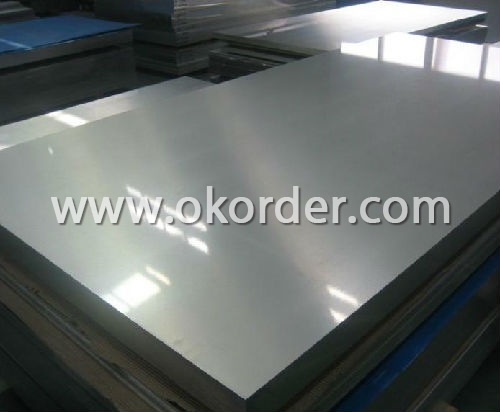

4. Surface of Stainless steel sheet : 2B, NO.1, BA, NO.4, Hairline, SB, Mirror finish, Anti-skid, Cherkered etc.

5. Size of Stainless steel sheet :

Thickness: 0.3-3mm (cold rolled), 3-40mm (hot rolled)

Width: 1000mm or 1219mm or 1240mm for cold rolled, 1500mm for hot rolled.

Length: As customers' request.

6. MOQ of Stainless steel sheet : 1 Ton

7. Payment terms: T/T or L/C

8. Packing ofStainless steel sheet : Seaworthy package with wooden or Iron pallets with the paper and the steel strip,

or as customers' request.

9. Delivery time of Stainless steel sheet: Usually about 7 days after we confirming the order, or according to your quantity.

If you have any demand, pls feel free to contact me.

- Q: What are the different grades of stainless steel used for strips?

- Different grades of stainless steel are utilized for strips, each possessing distinct properties and uses. Some commonly used grades include: 1. Austenitic stainless steel (e.g., 304, 316): This type is extensively employed for strips due to its exceptional corrosion resistance, high strength, and good formability. It finds applications in food processing equipment, kitchen appliances, and architectural projects. 2. Ferritic stainless steel (e.g., 430): Known for its magnetic properties and strong resistance to corrosion, especially in acidic environments. It is commonly utilized in automotive trim, kitchen utensils, and decorative strips. 3. Martensitic stainless steel (e.g., 410, 420): Recognized for its high strength, hardness, and resistance to wear. It is commonly used in cutlery, surgical instruments, and industrial applications that require hardness and corrosion resistance. 4. Duplex stainless steel (e.g., 2205): Offers a combination of high strength and resistance to corrosion. It is commonly used in chemical processing equipment, oil and gas pipelines, and marine applications. The grade selection depends on the specific application and desired properties, such as corrosion resistance, strength, formability, and magnetic properties.

- Q: Are stainless steel strips resistant to pitting?

- Yes, stainless steel strips are generally resistant to pitting. Pitting corrosion is a type of localized corrosion that causes small holes or pits to form on the surface of metals, including stainless steel. However, stainless steel has a high resistance to pitting due to its chromium content. Chromium forms a passive protective layer on the surface of stainless steel, which helps to prevent the metal from corroding. Additionally, stainless steel is often alloyed with other elements such as molybdenum and nickel, which further enhance its resistance to pitting corrosion. Therefore, stainless steel strips are commonly used in applications where corrosion resistance is crucial, such as in the construction, automotive, and food processing industries.

- Q: What is the weldability of stainless steel strips?

- Stainless steel strips possess exceptional weldability due to their excellent corrosion resistance and durability. This characteristic is attributed to their ability to be welded effortlessly using various welding techniques like TIG welding, MIG welding, and resistance welding. The weldability of stainless steel strips is primarily influenced by their low thermal conductivity. This quality affords better management of heat input during welding, thereby minimizing the risk of distortion or warping. Furthermore, stainless steel strips exhibit a relatively low carbon content, which aids in diminishing the formation of brittle intermetallic phases while welding. Nevertheless, it is essential to acknowledge that stainless steel strips may be susceptible to sensitization. This phenomenon occurs when chromium carbides form at grain boundaries due to elevated temperatures during welding. Consequently, the corrosion resistance of the heat-affected zone (HAZ) in the weld may be compromised. To address this concern, stainless steel strips are often obtainable in "low carbon" or "stabilized" grades, containing elements like titanium or niobium. These elements form robust carbide-forming compounds and prevent sensitization. To summarize, the weldability of stainless steel strips is typically excellent, thanks to their low thermal conductivity and low carbon content. However, precautions must be taken to avert sensitization and uphold the corrosion resistance of the welded joints.

- Q: Can 111 stainless steel strips be passivated to enhance corrosion resistance?

- Yes, 111 stainless steel strips can be passivated to enhance corrosion resistance. Passivation is a process that removes surface contaminants and forms a protective oxide layer on the stainless steel, which improves its resistance to corrosion.

- Q: Can stainless steel strips be used for jewelry findings?

- Yes, stainless steel strips can be used for jewelry findings. Stainless steel is a durable and corrosion-resistant material, making it suitable for various jewelry components such as clasps, jump rings, and connectors. Its strength and versatility make it a popular choice among jewelry designers.

- Q: Can stainless steel strips be used in food processing industries?

- Stainless steel strips find their application in the food processing industries. They are widely utilized due to their hygienic properties, resistance to corrosion, and long-lasting nature. Various uses of stainless steel strips include conveyor belts, food-grade equipment, storage tanks, and processing machinery. The smooth and non-porous surface of stainless steel facilitates effortless cleaning and maintenance, thereby preventing bacterial growth and ensuring food safety. Moreover, stainless steel exhibits resistance against chemicals and high temperatures, making it ideal for critical sanitization and sanitation requirements in food processing environments.

- Q: Can stainless steel strips be used for architectural cladding?

- Yes, stainless steel strips can be used for architectural cladding. Stainless steel is a popular choice for cladding in architectural projects due to its durability, corrosion resistance, and aesthetic appeal. It provides a sleek and modern look to buildings while also offering protection against the elements and easy maintenance. Stainless steel strips can be customized in various sizes and finishes to suit the specific design requirements of architectural cladding.

- Q: What is the fatigue strength of stainless steel strips?

- Various factors, such as the specific grade of stainless steel, the surface condition, and the manufacturing process, can lead to variations in the fatigue strength of stainless steel strips. In comparison to other materials, stainless steel is generally recognized for its high fatigue strength. Stainless steel strips find common use in industries like automotive, aerospace, and construction, where they undergo cyclic loading or repetitive stress. The fatigue strength denotes the maximum stress level that a material can endure for a specific number of cycles without failure. To evaluate the fatigue strength of stainless steel strips, fatigue testing is often employed. This involves subjecting a strip specimen to repeated loading and unloading cycles until failure occurs. The results are then used to determine the material's endurance or fatigue limit, which signifies the stress level below which the material can withstand an infinite number of cycles without failing. The fatigue strength of stainless steel strips typically falls within the range of 150 to 500 megapascals (MPa), depending on the grade of stainless steel. However, it's important to note that the fatigue strength can be affected by various factors, including the surface finish, presence of defects or notches, temperature, and environmental conditions. In summary, stainless steel strips generally exhibit high fatigue strength in comparison to other materials. The specific fatigue strength can vary based on the grade of stainless steel and other influencing factors, and it is typically determined through fatigue testing.

- Q: What is the minimum thickness available for stainless steel strips?

- The specific grade and manufacturer can cause variations in the minimum thickness of stainless steel strips. Nevertheless, it is possible for stainless steel strips to reach a thickness as low as 0.001 inches (0.0254 mm) or even less. These extremely thin stainless steel strips find frequent usage in precision-demanding and highly corrosion-resistant applications. It should be highlighted that the supplier and the customer's specific requirements may also influence the accessibility of these thin strips.

- Q: Can stainless steel strips be used in the chemical manufacturing industry?

- Yes, stainless steel strips can be used in the chemical manufacturing industry. Stainless steel is highly corrosion resistant, making it suitable for handling various chemicals and corrosive substances. It also offers excellent strength and durability, ensuring a long service life in harsh chemical environments. Additionally, stainless steel can withstand high temperatures, making it ideal for use in chemical manufacturing processes that involve heat.

1. Manufacturer Overview

| Location | Wuxi,China |

| Year Established | 2000 |

| Annual Output Value | Above US$16 Million |

| Main Markets | Chinese, Europe,South Africa |

| Company Certifications | ISO9001:2000; |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 30% |

| No.of Employees in Trade Department | 50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 80,000 square meters |

| No. of Production Lines | Above 7 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

Stainless Steel Sheet AISI 304

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 Ton m.t.

- Supply Capability:

- 5000ton m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords