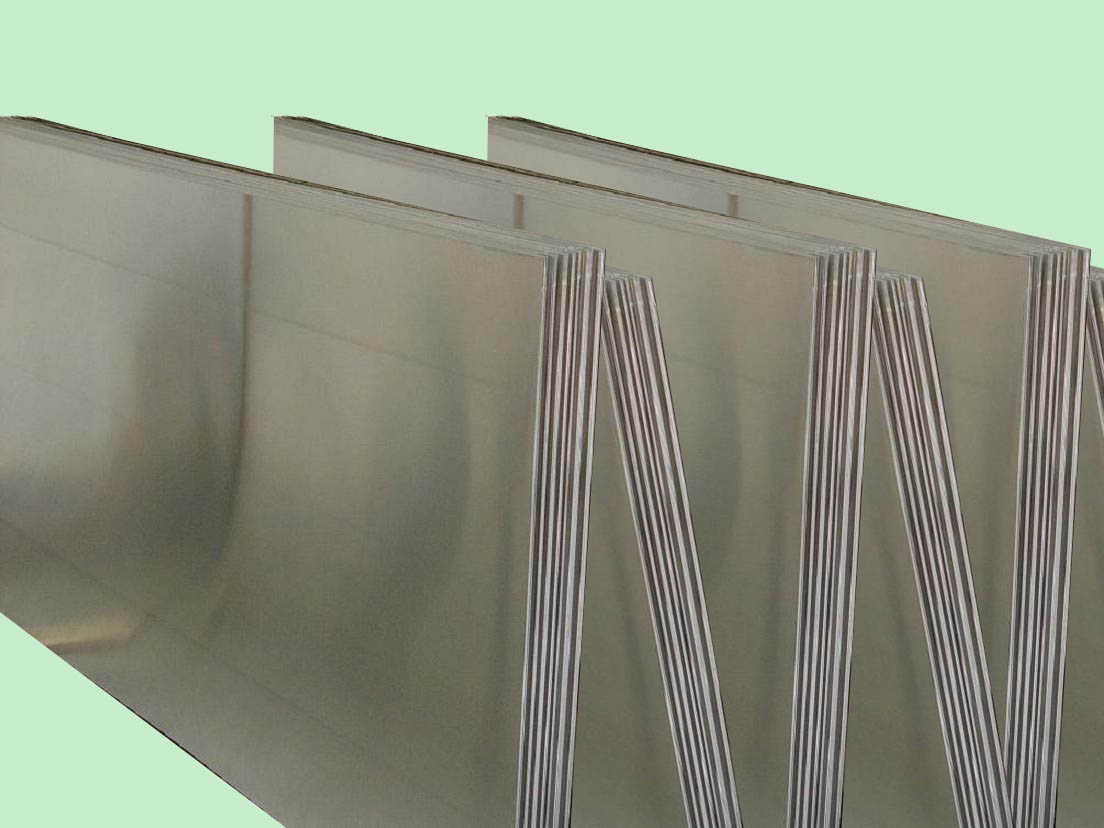

420 Stainless Steel Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Ton m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

420 Stainless Steel Sheet

1. Chemical composition

|

C |

Si |

Mn |

P |

S |

Ni |

Cr |

|

0.16-0.25 |

max1.00 |

max1.00 |

max0.04 |

max0.03 |

--- |

12.00-14.00 |

2. Mechanical properties

|

Yield Strength |

Tensile |

Elongation |

Hardness (HV) |

Hardness (HRB) |

|

≥225 |

≥520 |

≥ 18 |

≥234 |

≥97 |

3. Standard: AISI, ASTM, GB, EN, DIN, JIS

4. Surface: 2B, NO.1, BA, NO.4, Hairline, SB, Mirror finish, Anti-skid, Cherkered etc.

5. Size: Thickness: 0.3-3mm (cold rolled), 3-40mm (hot rolled)

Width: 1000mm or 1219mm or 1240mm for cold rolled, 1500mm for hot rolled.

Length: As customers' request.

6. MOQ: 1 Ton

7. Payment terms: T/T or L/C

8. Packing: Seaworthy package with wooden or Iron pallets with the paper and the steel strip, or as customers' request.

9. Delivery time: Usually about 7 days after we confirming the order, or according to your quantity.

If you have any question or demand, pls feel free to contact me.

- Q: Are stainless steel strips resistant to hydrogen embrittlement?

- Yes, stainless steel strips are generally resistant to hydrogen embrittlement. Stainless steel is known for its excellent corrosion resistance, and this property also extends to its resistance against hydrogen embrittlement. Hydrogen embrittlement is a phenomenon where hydrogen atoms penetrate the steel's crystal lattice, causing it to become brittle and susceptible to cracking or failure. However, stainless steel contains a high amount of chromium, which forms a passive oxide layer on its surface. This oxide layer acts as a protective barrier, preventing hydrogen atoms from diffusing into the steel and reducing the risk of embrittlement. Additionally, stainless steel strips are often made with austenitic grades, which have a high nickel content that further enhances their resistance to hydrogen embrittlement.

- Q: What is the minimum order quantity for stainless steel strips?

- The minimum order quantity for stainless steel strips may vary depending on the supplier or manufacturer. It is advisable to check with the specific supplier or manufacturer to determine their minimum order quantity requirements.

- Q: Are stainless steel strips prone to rusting?

- Stainless steel strips are generally not prone to rusting. Stainless steel is an alloy composed mainly of iron, chromium, and other elements, which gives it corrosion-resistant properties. The addition of chromium forms a protective layer on the surface of the steel called chromium oxide, which acts as a barrier against oxygen and moisture, preventing rust formation. However, certain conditions, such as exposure to chlorides, acids, or high humidity environments, can still cause stainless steel to corrode or stain. Therefore, while stainless steel strips are highly resistant to rusting, proper care and maintenance should still be exercised to ensure their longevity.

- Q: Are 111 stainless steel strips suitable for cryogenic storage containers?

- Yes, 111 stainless steel strips are suitable for cryogenic storage containers. 111 stainless steel is a type of austenitic stainless steel that is known for its excellent resistance to corrosion and high temperature. It is also known for its strength and durability. These properties make it suitable for use in cryogenic storage containers, which are designed to store materials at extremely low temperatures. The 111 stainless steel strips will be able to withstand the low temperatures without becoming brittle or losing their structural integrity. Additionally, the corrosion resistance of 111 stainless steel will ensure that the containers remain in good condition even when exposed to the moisture present in cryogenic environments. Overall, using 111 stainless steel strips in cryogenic storage containers is a reliable and effective choice.

- Q: What are the common uses of stainless steel strips in the pharmaceutical manufacturing process?

- Stainless steel strips play a crucial role in the pharmaceutical manufacturing process due to their unique properties and characteristics. Here are some common uses of stainless steel strips in pharmaceutical manufacturing: 1. Equipment fabrication: Stainless steel strips are extensively used for fabricating various pharmaceutical equipment such as mixing tanks, storage tanks, reactors, and piping systems. The corrosion resistance and hygienic properties of stainless steel make it ideal for maintaining a sterile environment and preventing contamination during the manufacturing process. 2. Pharmaceutical packaging: Stainless steel strips are commonly used for manufacturing pharmaceutical packaging materials such as vials, ampoules, and syringes. The high strength and durability of stainless steel strips ensure the protection and integrity of pharmaceutical products, especially those that are sensitive to external factors like moisture and temperature. 3. Cleanroom construction: Stainless steel strips are utilized in the construction of cleanrooms, which are critical for pharmaceutical manufacturing. These strips are used for creating partition walls, flooring, and ceilings, providing a sterile and controlled environment for the production of pharmaceutical products. 4. Conveyors and material handling systems: Stainless steel strips are employed in the construction of conveyors and material handling systems used in pharmaceutical manufacturing. These strips provide the necessary strength and resistance to chemicals and wear, ensuring the smooth and efficient movement of materials throughout the production process. 5. Filtration systems: Stainless steel strips are used in the fabrication of filtration systems, such as filter housings and filter cartridges. The anti-corrosive properties of stainless steel enable these filtration systems to effectively remove impurities, contaminants, and particles from pharmaceutical fluids and solutions. 6. Heat exchangers: Stainless steel strips are utilized in the construction of heat exchangers, which are vital for various pharmaceutical processes like sterilization, cooling, and heating. The excellent thermal conductivity of stainless steel enables efficient heat transfer, ensuring the precise control of temperature during the manufacturing process. Overall, stainless steel strips are indispensable in the pharmaceutical manufacturing process due to their corrosion resistance, durability, cleanliness, and ability to maintain a sterile environment. Their applications range from equipment fabrication to packaging, cleanroom construction, filtration, material handling, and heat exchange, playing a vital role in ensuring the quality and safety of pharmaceutical products.

- Q: Are stainless steel strips resistant to stress corrosion cracking?

- Yes, stainless steel strips are generally resistant to stress corrosion cracking. Stainless steel is known for its high corrosion resistance due to the presence of chromium, which forms a protective oxide layer on the surface of the metal. This oxide layer acts as a barrier against corrosive elements, including chloride ions, which are often responsible for stress corrosion cracking. However, it is important to note that the resistance to stress corrosion cracking can vary depending on the specific grade of stainless steel and the environment in which it is exposed. Some grades of stainless steel, such as austenitic stainless steels (e.g. 304, 316), exhibit excellent resistance to stress corrosion cracking in most environments. Nevertheless, in certain aggressive environments, such as those containing high concentrations of chloride ions or under high-stress conditions, even stainless steel can be susceptible to stress corrosion cracking. In such cases, it may be necessary to use higher alloyed grades of stainless steel or apply additional corrosion prevention methods to ensure optimal resistance to stress corrosion cracking. Overall, stainless steel strips are generally considered to be highly resistant to stress corrosion cracking, making them a reliable choice for various applications in corrosive environments.

- Q: Are stainless steel strips suitable for marine applications?

- Yes, stainless steel strips are suitable for marine applications. Stainless steel is highly resistant to corrosion, making it ideal for use in marine environments where exposure to saltwater and moisture is common. It offers excellent durability, strength, and long-term performance, making it a popular choice for various marine applications such as boat fittings, marine hardware, and offshore structures.

- Q: What are the common weight tolerances for stainless steel strips?

- The common weight tolerances for stainless steel strips can vary depending on the specific grade and thickness of the strip. However, typical weight tolerances for stainless steel strips range from +/- 5% to +/- 10% of the specified weight.

- Q: Can stainless steel strips be used for architectural sculptures?

- Yes, stainless steel strips can indeed be used for architectural sculptures. Stainless steel is a versatile and durable material that can be shaped, welded, and polished into various artistic forms. Its resistance to corrosion and weathering makes it suitable for outdoor installations, while its sleek appearance adds a modern and aesthetic touch to architectural sculptures.

- Q: Can stainless steel strips be used in the production of automotive exhaust systems?

- Yes, stainless steel strips can be used in the production of automotive exhaust systems. Stainless steel strips are often preferred for exhaust systems due to their high temperature resistance, corrosion resistance, and durability. They can withstand the extreme heat and corrosive gases generated by the engine, making them a suitable choice for this application.

1. Manufacturer Overview

| Location | Guangzhou,China |

| Year Established | 2001 |

| Annual Output Value | Above US$0.5 Million |

| Main Markets | Southeast Asia, Europe |

| Company Certifications | ISO 9001:2008; |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 30% |

| No.of Employees in Trade Department | 10 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 30,000 square meters |

| No. of Production Lines | Above 7 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

420 Stainless Steel Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Ton m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords