STAINLESS STEEL PLATE GOOD QUALITY from CHINA

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1,the description of the stainless steel plate

we stocks a wide range of good quality stainless steel plate in 304/304L, 304 straight grade, 316/316L and 321 plate. These grades are part of the austenitic family of stainless. Austenitic stainless steel is one of the most widely used and versatile type of steel. While 304L stainless steel plates have excellent corrosion resistance, 316/316L plates have higher nickel content than 304 and 304L giving them even better corrosion resistance especially in marine applications. Type 321 ss plates are a good choice for applications where heat is an issue. 321 can be used in applications up to 900 degrees Celsius where 304L is normally used up to 500 degrees Celsius.

2,main features of the stainless steel plate

Grade: 300 Series, 201 202 304 304L 316 316L 310S

Standard: ASTM, AISI, DIN, EN, GB, JIS

Length: 1000mm-6000mm

Thickness:0.3mm-3mm, as your reqquirement

Width: 1000mm-2000mm

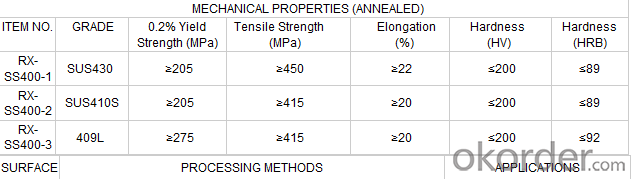

3,mechanical properties

4,STAINLESS STEEL PLATE APPLICATIONS:

Food Processing and handling

Heat exchangers

Chemical process vessels

Conveyors

Architectural

Marine

Pharmaceutical equipment

5,FAQ

1. Q: What are your advantageous Products?

A: We specialized in 400 series cold rolled stainless steel coils and plates. Our main products are 430, 410S and 409L.

We also supply stainless steel strips and strips in coil as requested.

2. Q: Can you make DDQ ( Deep Drawing Quality)?

A: Yes, we can. Our material can be used for stainless steel pots, stainless steel sinks, stainless steel bowls etc. U can tell us your usage, and we will adjust the mechanical propertise to meet your requirement.

3. Q: What is the application of 400 series stainless steel?

A: 410S stainless steel and 430 stainless steel are widely used for: kitchenware, tableware, cutleries, stainless steel pots, plates & bowls, sinks, gas stove, disinfection cabinet, household appliances, construction decorations etc. 409L stainless steel is usually used for exhaust pipe.

4. Q: How can I get the samples?

A: Our samples are free, but we hope customers to pay for the freight fee. There are two ways to send the samples.

1. U can provide us with your express account no. and contact information for shipping if u have the accout no.

2. If u do not have an express account, u can remit freight fee in advance. As soon as we get the freight fee, we will arrange the samples for u.

3. We hope to know the application of the stainless steel, so that we can send the right samples.

5. Q: How much for sending the samples?

A: The freight fee depends on the sample weight, packing size, and your area. We will find the best shipping forwarder for you.

- Q: Are stainless steel sheets suitable for architectural louvers or screens?

- Yes, stainless steel sheets are suitable for architectural louvers or screens. Stainless steel is a highly durable and corrosion-resistant material, making it ideal for outdoor applications such as louvers or screens. It can withstand harsh weather conditions, including rain, UV exposure, and temperature fluctuations, without losing its structural integrity or aesthetic appeal. Stainless steel also offers a sleek and modern appearance, which enhances the overall design of architectural louvers or screens. Additionally, stainless steel sheets can be easily customized to create various patterns, shapes, and sizes, allowing for flexibility in design and functionality. Overall, stainless steel sheets are a reliable and long-lasting choice for architectural louvers or screens.

- Q: Can stainless steel sheets be used for decorative backsplashes?

- Stainless steel sheets are an excellent option for decorative backsplashes. Known for its versatility and durability, stainless steel is widely used in kitchen and interior design. Its sleek and modern appearance makes it a popular choice for contemporary and industrial-style kitchens. In addition to being visually appealing, stainless steel backsplashes offer practical benefits as well. They are resistant to heat, stains, and water, making them highly functional. Furthermore, stainless steel is easy to clean and maintain, making it an ideal choice for busy kitchens. Whether you prefer a polished, brushed, or patterned finish, stainless steel sheets can be customized to match your aesthetic preferences. This allows you to create a stylish and attention-grabbing backsplash that complements your overall design scheme.

- Q: What are the different welding techniques used for stainless steel sheets?

- There are several welding techniques commonly used for stainless steel sheets, including Tungsten Inert Gas (TIG) welding, Metal Inert Gas (MIG) welding, and Shielded Metal Arc Welding (SMAW). TIG welding is often preferred for its precise control and ability to produce high-quality welds with minimal distortion. MIG welding is a faster process that uses a consumable wire electrode and an inert gas to protect the weld zone. SMAW, also known as stick welding, is a versatile technique that can be used in various positions and is suitable for thicker stainless steel sheets. Each technique has its advantages and is chosen based on factors such as the thickness of the sheets, desired weld quality, and application requirements.

- Q: Are stainless steel sheets suitable for cryogenic applications?

- Yes, stainless steel sheets are suitable for cryogenic applications. Stainless steel is known for its excellent mechanical properties, including high strength and toughness, which make it suitable for low-temperature environments. Additionally, stainless steel has good corrosion resistance, which is crucial when exposed to cryogenic temperatures. It maintains its mechanical properties and does not become brittle at ultra-low temperatures. Therefore, stainless steel sheets are commonly used in cryogenic applications such as storage tanks, pipelines, and equipment for liquefied natural gas (LNG), liquid nitrogen, and other cryogenic fluids.

- Q: Can stainless steel sheets be used for food preparation surfaces?

- Food preparation surfaces can indeed utilize stainless steel sheets. The reason behind stainless steel's popularity for such surfaces is its remarkable characteristics. Being non-porous, it avoids the absorption of any liquids or bacteria that can contaminate the food. Moreover, stainless steel exhibits resistance to corrosion, staining, and rusting, thereby ensuring its durability and longevity for food preparation surfaces. Furthermore, stainless steel can be easily cleaned due to its ability to withstand high temperatures and resistance to most cleaning agents. This fact makes it a hygienic option for food preparation surfaces, as it allows for thorough sanitization to prevent bacterial growth. In conclusion, stainless steel sheets provide a secure and practical alternative for food preparation surfaces.

- Q: How do you prevent galvanic corrosion when using stainless steel sheets?

- To prevent galvanic corrosion when using stainless steel sheets, there are several measures you can take: 1. Avoid direct contact with dissimilar metals: Galvanic corrosion occurs when two different metals come into contact in the presence of an electrolyte, such as moisture. To prevent this, ensure stainless steel sheets are not in direct contact with dissimilar metals, especially those with a higher anodic index, such as aluminum or copper. If contact is unavoidable, use insulating materials like plastic or rubber gaskets to separate the metals. 2. Select compatible fasteners: When fastening stainless steel sheets, it is crucial to choose fasteners made from the same or compatible metals. Using dissimilar metals can create galvanic cells, leading to corrosion. Stainless steel fasteners or those made from materials with similar corrosion resistance, like galvanized steel, are recommended. 3. Use protective coatings: Applying protective coatings to stainless steel sheets can provide an additional barrier against galvanic corrosion. Consider using paint, epoxy, or other appropriate coatings that are compatible with stainless steel. These coatings act as a sacrificial layer, preventing direct contact between the stainless steel and the surrounding environment. 4. Insulate electrical connections: If stainless steel sheets are involved in electrical systems, ensure proper insulation of electrical connections. This prevents the flow of electrical current between dissimilar metals, reducing the risk of galvanic corrosion. Insulating materials like plastic or rubber sleeves can be used to separate the metals and inhibit the formation of galvanic cells. 5. Control environmental factors: Galvanic corrosion is often accelerated in the presence of moisture, saltwater, or acidic environments. Controlling these factors can help prevent corrosion on stainless steel sheets. Regularly clean and dry the sheets, especially in areas where moisture accumulates. Avoid exposing the sheets to saltwater or corrosive chemicals, and maintain proper ventilation to minimize humidity levels. By implementing these preventive measures, you can significantly reduce the risk of galvanic corrosion when using stainless steel sheets. However, it is important to regularly inspect the sheets for any signs of corrosion and address them promptly to maintain their integrity and longevity.

- Q: What are the different types of stainless steel sheet finishes?

- A variety of stainless steel sheet finishes are accessible, each possessing distinctive traits and appearances. Some of the most prevalent finishes comprise: 1. No.1 Finish: Termed "hot rolled annealed and pickled" (HRAP), this finish is the most fundamental and widely employed. It exhibits a dull, coarse surface with visible grain lines. 2. No.2B Finish: By cold rolling the stainless steel sheet and subsequently annealing it in a controlled environment, this finish is achieved. It possesses a smooth, reflective surface with a slight haze. 3. No.2D Finish: Similar to No.2B, this finish is acquired through cold rolling and annealing. However, it has a marginally rougher surface and is commonly utilized for applications not necessitating a highly reflective finish. 4. No.3 Finish: By meticulously polishing the stainless steel sheet using abrasive belts or brushes, this finish is accomplished. It presents a semi-reflective surface with a grainy appearance. 5. No.4 Finish: Termed "brushed finish," this finish is attained by utilizing fine abrasive belts or brushes to create a consistent, linear grain pattern on the surface. It exhibits a matte appearance and is typically employed in architectural and decorative applications. 6. No.6 Finish: Through further polishing the stainless steel with finer abrasives, this finish is realized, resulting in a smoother and more reflective surface. 7. No.7 Finish: Analogous to No.6, this finish is accomplished by employing even finer abrasives, culminating in a highly reflective surface with a mirror-like appearance. 8. No.8 Finish: Also known as the "mirror finish," this represents the highest level of polish achievable on stainless steel. It showcases a flawless, reflective surface that is frequently utilized in decorative and high-end applications. Besides these conventional finishes, there are also specialized finishes obtainable, such as embossed, patterned, or colored finishes, which can further augment the aesthetic allure of stainless steel sheets. The selection of a finish relies on the specific application and desired appearance, with each finish offering its own distinct advantages and characteristics.

- Q: 304 stainless steel plate 1*1219*C what do you mean?

- 304 is the most widely used stainless steel, heat-resistant steel. For food production equipment, general chemical equipment, nuclear energy and so on304 stainless steel chemical composition

- Q: What's the difference between stainless steel 304 2B board and Ba board?

- 304 stainless steel2B board: without glossBA board: an ordinary mirror that shines a littleStainless steel and mirror, that is, 8K board, like a mirror

- Q: Can stainless steel sheets be polished?

- Yes, stainless steel sheets can be polished. Polishing stainless steel sheets helps to improve their appearance by creating a smooth and shiny surface. The process typically involves using abrasive materials such as sandpaper, polishing compounds, or polishing machines to remove any imperfections or scratches on the surface of the stainless steel sheet. This can be done manually or with the help of specialized equipment. Polishing stainless steel sheets not only enhances their aesthetic appeal but also helps to prevent corrosion and improve their resistance to staining.

Send your message to us

STAINLESS STEEL PLATE GOOD QUALITY from CHINA

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords