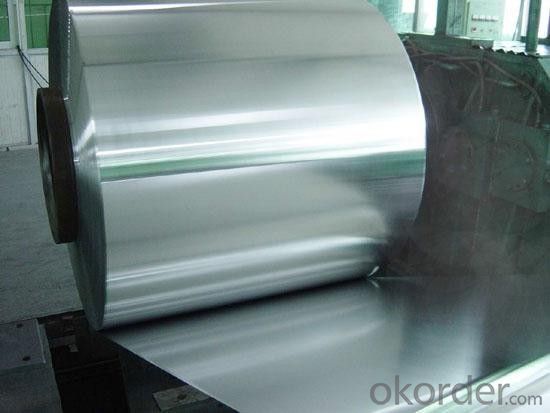

Stainless Steel sheet 304 with 4MM Thickness in high quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot sale stainless steel sheet 201/202/304/304l/316/316l/430 in china alibaba

Description of Stainless Steel Sheet:

Description | steel sheet,hot rolled steel sheet,cold rolled steel sheet, steel sheet,sheet,steel plate |

Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

Application | Steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

Packaging | Standard export sea-worthy packing |

Delivery time | 10-30 days |

Quality | No.1 |

Productivity | 500 tons/Day |

Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

Contacts | If you have any question,please feel free contact me. |

Stainless steel sheet surface finish characteristics

Surface finish | Characteristics and application |

2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

No.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

No.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

Main Features of stainless steel sheet :

•Escalator, Elevator, Doors

•Furniture

•Production tools, Kitchen appliances, freezers, cold rooms

•Auto Parts

•Machinery and Packaging

•Equipment and Medical devices

•Transport system

Product Details:

Sandard Seaworth Packing(wooden packing with water proof paper)

FAQ:

1. What's the quality?

very fine

2. How long get reply?

within 24 hours

If you have any question about stainless steel sheets,donot forget to sending the email to Us! You will get the competitive Price and have a very good experience about the Buying Process! CNBM International Corporation is always your trustful friend!

- Q: Can stainless steel sheets be recycled?

- Yes, stainless steel sheets can be recycled. Stainless steel is a highly recyclable material, and it can be melted down and reused to produce new stainless steel products. Recycling stainless steel not only conserves natural resources but also helps to reduce waste and minimize environmental impact.

- Q: Are stainless steel sheets suitable for desalination plants?

- Indeed, desalination plants find stainless steel sheets to be quite appropriate. Stainless steel exhibits remarkable resistance against corrosion and can endure the severe circumstances encountered in such plants, such as contact with saltwater and exposure to high temperatures. Its exceptional durability and mechanical characteristics render it an ideal material for multiple components in desalination plants, such as piping, heat exchangers, and tanks. Furthermore, stainless steel possesses commendable hygiene properties, rendering it suitable for desalination plants that necessitate stringent cleanliness standards. Moreover, the fabrication and installation of stainless steel sheets are effortless, allowing for efficient construction and maintenance procedures in desalination plants.

- Q: What are the different types of etched finishes available for stainless steel sheets?

- Stainless steel sheets come in a range of etched finishes, each with its own unique and distinctive look. Let's explore some of the most common options: 1. Brushed Finish: A popular choice, this etched finish involves using a fine abrasive material to create a smooth and satin-like texture on the surface of the stainless steel sheet. 2. Bead Blasted Finish: For a matte and slightly rough appearance, small glass or ceramic beads are blasted onto the sheet at high pressure, resulting in a non-directional and uniform texture. 3. Mirror Finish: Also known as a No. 8 finish, this etched option gives the stainless steel sheet a flawless and shiny appearance. It involves a series of grinding, buffing, and polishing processes to create a highly reflective and mirror-like surface. 4. Satin Finish: Similar to the brushed finish but with a finer texture, this etched option uses a finer abrasive material during the brushing process, resulting in a soft and elegant appearance. 5. Patterned Finish: This etched finish allows for creative and customizable options, as it involves creating various patterns or designs on the sheet's surface. Techniques such as laser etching, chemical etching, or embossing can be used to achieve this effect. These different etched finishes offer a wide range of aesthetic choices for stainless steel sheets, making them suitable for various architectural, decorative, and industrial applications. The choice of finish depends on the desired appearance, functionality, and intended use of the sheet.

- Q: Are stainless steel sheets suitable for food storage containers?

- Yes, stainless steel sheets are suitable for food storage containers. Stainless steel is a popular choice for food storage containers due to its many beneficial properties. Firstly, stainless steel is non-reactive, meaning it does not interact with or leach any harmful chemicals into the food, ensuring that the taste and quality of the food is preserved. Additionally, stainless steel is resistant to corrosion, rust, and staining, making it a durable and long-lasting material for food storage containers. It is also easy to clean and maintain, as it does not absorb odors or flavors from previous food items. Furthermore, stainless steel is a hygienic material, as it does not harbor bacteria or other pathogens, ensuring that your food remains safe and healthy. Overall, stainless steel sheets are an excellent choice for food storage containers due to their suitability for contact with food, durability, and hygienic properties.

- Q: What are the different types of embossed patterns available for stainless steel sheets?

- There are several different types of embossed patterns available for stainless steel sheets. Some of the most common patterns include: 1. Diamond pattern: This pattern features a series of diamond-shaped raised protrusions on the surface of the stainless steel sheet. It is a popular choice for adding visual interest and texture to various applications. 2. Linen pattern: The linen pattern is characterized by a series of parallel lines that create a textured appearance resembling linen fabric. This pattern is often used in architectural and interior design applications. 3. Squares pattern: As the name suggests, this pattern consists of a series of square-shaped raised protrusions on the stainless steel sheet. It provides a clean and modern look, making it suitable for many different applications. 4. Leather pattern: This embossed pattern mimics the texture and appearance of leather. It adds a touch of elegance and sophistication to stainless steel sheets, making it a popular choice for decorative purposes. 5. Moire pattern: The moire pattern features a wavy or rippled design that creates an optical illusion effect. It adds a unique and dynamic visual element to stainless steel sheets, making them stand out in various applications. 6. Checkerplate pattern: This pattern is characterized by a series of raised squares or rectangles arranged in a checkered pattern. It is commonly used for its high slip resistance, making it ideal for applications where safety is a concern, such as stairs or ramps. These are just a few examples of the many different embossed patterns available for stainless steel sheets. The choice of pattern depends on the desired aesthetic, functionality, and specific application requirements. Whether it's for architectural, interior design, or industrial purposes, there is a wide range of embossed patterns to choose from to meet various needs.

- Q: How do you remove fingerprints from brushed stainless steel sheets?

- To remove fingerprints from brushed stainless steel sheets, you can follow these simple steps: 1. Start by gathering the necessary cleaning supplies. You will need a microfiber cloth, mild dish soap, warm water, and a stainless steel cleaner or vinegar. 2. Begin by dampening the microfiber cloth with warm water. Make sure the cloth is not soaking wet, just slightly damp. 3. Gently wipe the stainless steel surface in the direction of the grain. It is important to always follow the grain to avoid causing scratches or streaks. 4. If the fingerprints persist, you can add a small amount of mild dish soap to the damp cloth and continue wiping the surface. Be sure to rinse the cloth thoroughly after applying the soap. 5. If the fingerprints are still visible, you can use a stainless steel cleaner specifically designed for brushed stainless steel surfaces. Apply a small amount of the cleaner onto the microfiber cloth and wipe the surface in the direction of the grain. Remember to follow the manufacturer's instructions for the specific cleaner you are using. 6. Alternatively, you can use white vinegar as a natural cleaning solution. Dampen a cloth with vinegar and gently wipe the surface in the direction of the grain. Vinegar can help remove fingerprints and restore shine. 7. Once you have removed the fingerprints, use a dry microfiber cloth to buff the surface gently. This will help remove any remaining streaks and give the stainless steel a polished finish. Remember to always test any cleaning solution on a small, inconspicuous area of the stainless steel sheet before applying it to the entire surface. Additionally, avoid using abrasive materials or cleaners that contain chlorine or bleach, as they can damage the brushed finish of the stainless steel.

- Q: Can stainless steel sheets be used for bus shelters?

- Yes, stainless steel sheets can be used for bus shelters. Stainless steel is a durable and weather-resistant material, making it suitable for outdoor applications like bus shelters. It offers longevity, easy maintenance, and a modern aesthetic.

- Q: How do I prevent discoloration on stainless steel sheets?

- To prevent discoloration on stainless steel sheets, there are a few measures you can take: 1. Regular cleaning: Stainless steel sheets should be cleaned regularly using mild soap or a stainless steel cleaner. Avoid using abrasive cleaners or scrubbing brushes, as they can scratch the surface and make it more prone to discoloration. 2. Avoid harsh chemicals: Avoid using harsh chemicals, bleach, or chlorine-based cleaners on stainless steel sheets, as they can cause discoloration. If any spills occur, clean them immediately to prevent staining. 3. Proper ventilation: Ensure proper ventilation in the area where stainless steel sheets are installed. This is especially important in areas where chemicals or fumes are present, as they can react with stainless steel and cause discoloration. 4. Protective coatings: Applying a protective coating to stainless steel sheets can help prevent discoloration. There are various protective coatings available in the market designed specifically for stainless steel. These coatings create a barrier between the steel and external factors, reducing the chances of discoloration. 5. Regular maintenance: Regularly inspect the stainless steel sheets for any signs of discoloration or damage. Address any issues promptly to prevent further deterioration. By following these preventative measures, you can minimize the risk of discoloration on stainless steel sheets and maintain their aesthetic appeal for a longer period.

- Q: What are the different types of stainless steel sheet textures available?

- A variety of stainless steel sheet textures are available, each offering a distinct aesthetic and functional appeal. Some commonly used textures include: 1. Brushed: This texture is achieved by brushing the stainless steel surface with abrasive materials in one direction, resulting in a smooth, satin-like finish commonly found in kitchen appliances and decorative applications. 2. Mirror: As the name suggests, this texture creates a highly reflective and mirror-like surface. It is achieved by progressively polishing the stainless steel sheet with finer abrasives until a reflective finish is obtained. Mirror-textured stainless steel sheets are often used in architectural and decorative applications. 3. Embossed: This texture involves imprinting patterns or designs onto the stainless steel sheet using embossing rollers. The raised patterns add depth and visual interest to the surface, making it a popular choice for interior design applications such as wall cladding or elevator panels. 4. Perforated: This texture involves creating a pattern of holes or perforations on the stainless steel sheet. It allows for the passage of light, air, or liquids while adding a decorative element to the surface. Perforated stainless steel sheets are commonly used in architectural, interior design, and filtration applications. 5. Etched: This texture is achieved by chemically etching the stainless steel surface using acid or other corrosive substances. The etching process creates a pattern or design on the surface, resulting in a visually appealing, textured finish. Etched stainless steel sheets are often used in decorative applications such as signage, elevator doors, or wall panels. 6. Hammered: This texture involves using hammers or other tools to create a hammered or dimpled pattern on the stainless steel sheet. It adds a rustic, textured look to the surface and is commonly used in architectural and decorative applications. These examples showcase the range of stainless steel sheet textures available. Depending on desired aesthetics and functional requirements, there are numerous other textures and finishes that can be applied to stainless steel sheets to achieve different looks and effects.

- Q: What is the strength of stainless steel sheets?

- Several factors contribute to the strength of stainless steel sheets. Firstly, stainless steel is an alloy of iron and chromium, which grants it excellent resistance to corrosion. This corrosion resistance renders stainless steel sheets ideal for various applications, even in environments where they may be exposed to moisture, chemicals, or extreme temperatures. In addition to corrosion resistance, stainless steel sheets possess high tensile strength. Tensile strength refers to the maximum amount of tensile stress a material can endure before failure. Stainless steel sheets have a high tensile strength, enabling them to withstand heavy loads and resist deformation or breaking under pressure. Moreover, stainless steel sheets exhibit exceptional durability and hardness. This means they can endure wear and tear, making them suitable for applications that require long-lasting and robust materials. Stainless steel sheets also have a high resistance to heat, allowing them to maintain their structural integrity even at elevated temperatures. Another advantage of stainless steel sheets is their versatility. They can be shaped and sized in various ways, making them suitable for a wide range of applications. Additionally, stainless steel sheets can be easily formed, welded, and machined, allowing for customization to meet specific requirements. Overall, the strength of stainless steel sheets lies in their corrosion resistance, high tensile strength, durability, hardness, heat resistance, and versatility. These properties establish stainless steel sheets as a reliable and trusted material in numerous industries, including construction, automotive, aerospace, food processing, and many others.

Send your message to us

Stainless Steel sheet 304 with 4MM Thickness in high quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords