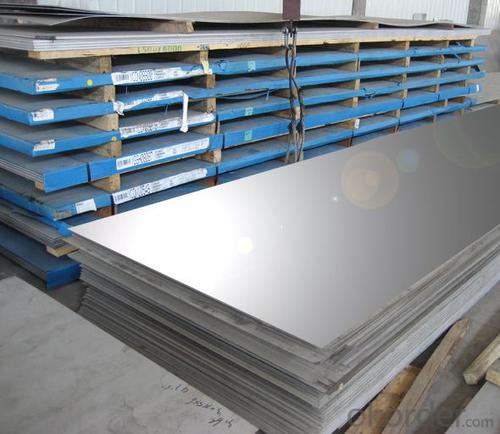

Stainless Steel plate and sheet 410 no.4 finish

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot sale stainless steel sheet 201/202/304/304l/316/316l/430

Description of Stainless Steel Sheet:

Description | steel sheet,hot rolled steel sheet,cold rolled steel sheet, steel sheet,sheet,steel plate |

Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

Application | Steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

Packaging | Standard export sea-worthy packing |

Delivery time | 10-30 days |

Quality | No.1 |

Productivity | 500 tons/Day |

Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

Contacts | If you have any question,please feel free contact me. |

Stainless steel sheet surface finish characteristics

Surface finish | Characteristics and application |

2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

No.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

No.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

Main Features of stainless steel sheet :

•Escalator, Elevator, Doors

•Furniture

•Production tools, Kitchen appliances, freezers, cold rooms

•Auto Parts

•Machinery and Packaging

•Equipment and Medical devices

•Transport system

Product Details:

Sandard Seaworth Packing(wooden packing with water proof paper)

FAQ:

1. What's the quality?

very fine

2. How long get reply?

within 24 hours

If you have any question about stainless steel sheets,donot forget to sending the email to Us! You will get the competitive Price and have a very good experience about the Buying Process! CNBM International Corporation is always your trustful friend!

- Q: Are stainless steel sheets suitable for structural applications?

- Yes, stainless steel sheets are suitable for structural applications. Stainless steel is a versatile and durable material that offers a high strength-to-weight ratio, making it ideal for various structural applications. It offers excellent corrosion resistance, which is important for structures that are exposed to harsh environments or chemicals. Stainless steel sheets can be used in the construction of bridges, buildings, and other structural components where strength and durability are necessary. Additionally, stainless steel is a sustainable material as it is 100% recyclable, further enhancing its suitability for structural applications.

- Q: How do you remove scratches from stainless steel sheets?

- There are a few methods you can try to remove scratches from stainless steel sheets. One option is to use a non-abrasive cleaner or stainless steel polish, applying it with a soft cloth and gently rubbing the scratched area in a circular motion. Another method involves making a paste using baking soda and water, applying it to the scratch, and gently rubbing it with a soft cloth. Additionally, you can use a fine-grit sandpaper to lightly buff the scratch in the direction of the grain. Remember to always test these methods on a small, inconspicuous area first to ensure they do not damage the stainless steel.

- Q: What are the different finishes available for stainless steel sheets?

- There are several different finishes available for stainless steel sheets, each offering a unique look and level of protection. 1. No. 1 Finish: This is the most common and basic finish for stainless steel sheets. It is a hot-rolled finish that appears dull and rough, with visible grain lines. It is typically used for industrial applications where appearance is not a major concern. 2. No. 2B Finish: This is a bright, cold-rolled finish that is slightly reflective. It has a smooth surface with a matte finish and is commonly used for decorative purposes, such as in architectural applications or for kitchen appliances. 3. No. 4 Finish: Also known as brushed or satin finish, it has a fine polishing grit line that creates a distinctive look. This finish is often used for decorative applications, such as for elevator doors or trim, and can hide minor surface imperfections. 4. No. 8 Mirror Finish: This is the most reflective finish available for stainless steel sheets. It has a highly polished, mirror-like surface that is smooth and shiny. This finish is often used for decorative purposes, such as in architectural features or decorative trim. 5. Hairline Finish: This finish features a very fine, brushed texture that is similar to the grain of hair. It provides a subtle, elegant appearance and is commonly used for decorative and architectural applications. 6. Embossed Finish: This finish involves creating a pattern or design on the surface of the stainless steel sheet through embossing or stamping. It adds texture and visual interest to the sheet and is often used for decorative purposes. It is important to note that the availability of these finishes may vary depending on the supplier and the specific stainless steel grade being used.

- Q: Are stainless steel sheets corrosion-resistant?

- Yes, stainless steel sheets are corrosion-resistant.

- Q: Why do galvanized and stainless steel sheets buy more expensive than thin ones?

- Galvanized sheet refers to the surface coated with a layer of zinc steel plate. Zinc plating is an economical and effective method of corrosion protection, and about half of the world's zinc production is used in this process.

- Q: Are stainless steel sheets suitable for escalator claddings?

- Yes, stainless steel sheets are suitable for escalator claddings. Stainless steel is a durable and corrosion-resistant material, making it an excellent choice for high-traffic areas like escalators. It is also easy to clean and maintain, which is important in public spaces. Additionally, stainless steel has a sleek and modern appearance that can enhance the overall aesthetic of the escalator.

- Q: Are stainless steel sheets resistant to intergranular corrosion?

- Yes, stainless steel sheets are generally resistant to intergranular corrosion. This is because stainless steel contains a high percentage of chromium, which forms a protective oxide layer on the surface of the metal. This oxide layer acts as a barrier, preventing the metal from coming into contact with corrosive elements in the environment. However, in certain conditions, such as exposure to high temperatures or welding processes, the chromium in stainless steel can be depleted, leading to the formation of chromium carbides at the grain boundaries. This can result in intergranular corrosion, also known as sensitization. To mitigate this, stainless steel sheets can be treated through a process called stabilization, which involves adding elements like titanium or niobium to the steel to bind with the carbon and prevent the formation of chromium carbides. Overall, stainless steel sheets are highly resistant to intergranular corrosion, but precautions should be taken in specific situations to maintain their corrosion-resistant properties.

- Q: Are stainless steel sheets suitable for elevator doors?

- Stainless steel sheets make for suitable elevator doors. They are a popular pick for this purpose because they are durable, resistant to corrosion, and aesthetically pleasing. Elevator doors endure constant use and exposure to various elements, which is why stainless steel is an ideal material. It doesn't easily rust or corrode. Furthermore, stainless steel sheets are easy to maintain and clean, ensuring a long-lasting and visually appealing appearance. The versatility of stainless steel also allows for customization in terms of finishes, textures, and patterns, which means elevator doors can be designed to match the desired aesthetic of the building or space. In summary, stainless steel sheets are a reliable and fitting option for elevator doors.

- Q: What is the thickness range available for stainless steel sheets?

- The thickness range available for stainless steel sheets varies depending on the specific type and grade of stainless steel. However, commonly available stainless steel sheets come in thicknesses ranging from 0.4mm to 6.0mm. Thinner sheets are often used for applications that require flexibility and light weight, while thicker sheets are typically used for structural purposes that require higher strength and durability. It is important to note that customized thicknesses can also be produced based on specific project requirements.

- Q: What is the minimum thickness available for stainless steel sheets?

- The minimum thickness available for stainless steel sheets can vary depending on the specific grade and manufacturing capabilities, but it is typically around 0.4 millimeters (0.0157 inches) or even thinner.

Send your message to us

Stainless Steel plate and sheet 410 no.4 finish

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords