Stainless Steel sheet 410 with No.4 Surface Treatment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot sale stainless steel sheet 201/202/304/304l/310S/309S/316L/316Ti/316/316l/321,410/420/430/444/443/409L, and 904L.

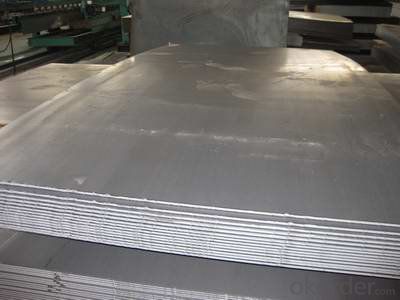

Description of Stainless Steel Sheet:

Description | steel sheet,hot rolled steel sheet,cold rolled steel sheet, steel sheet,sheet,steel plate |

Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

Application | Steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

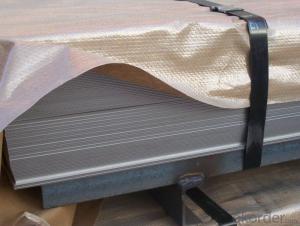

Packaging | Standard export sea-worthy packing |

Delivery time | 10-30 days |

Quality | No.1 |

Productivity | 500 tons/Day |

Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

Contacts | If you have any question,please feel free contact me. |

Stainless steel sheet surface finish characteristics

Surface finish | Characteristics and application |

2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

No.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

No.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

Main Features of stainless steel sheet :

•Escalator, Elevator, Doors

•Furniture

•Production tools, Kitchen appliances, freezers, cold rooms

•Auto Parts

•Machinery and Packaging

•Equipment and Medical devices

•Transport system

Product Details:

Sandard Seaworth Packing(wooden packing with water proof paper)

FAQ:

1. What's the quality?

very fine

2. How long get reply?

within 24 hours

If you have any question about stainless steel sheets,donot forget to sending the email to Us! You will get the competitive Price and have a very good experience about the Buying Process! CNBM International Corporation is always your trustful friend!

- Q: What are the limitations of using stainless steel sheets?

- Some limitations of using stainless steel sheets include their high initial cost, susceptibility to scratching, potential for corrosion in certain environments, and difficulty in shaping complex designs. Additionally, stainless steel sheets are relatively heavy, which can be a disadvantage in certain applications where weight is a concern.

- Q: What is the corrosion resistance of stainless steel sheets in saltwater?

- Stainless steel sheets have excellent corrosion resistance in saltwater environments. The high levels of chromium present in stainless steel enable the formation of a passive oxide layer on the surface, which acts as a protective barrier against corrosion. This oxide layer is highly resistant to saltwater, preventing the metal from being directly exposed to the corrosive effects of the saltwater. Additionally, stainless steel alloys such as 316 and 316L contain molybdenum, which further enhances their resistance to pitting and crevice corrosion in saltwater. Overall, stainless steel sheets are a preferred choice for applications in saltwater environments due to their exceptional corrosion resistance properties.

- Q: Can stainless steel sheets be used for elevator ceilings?

- Elevator ceilings can indeed utilize stainless steel sheets. The durability, sleek look, and corrosion resistance of stainless steel make it a favored option for this purpose. Its adaptability allows it to be shaped and sized to fit diverse elevator designs. Moreover, stainless steel sheets possess outstanding fire resistance and can endure high temperatures, ensuring safety when used for elevator ceilings. Furthermore, stainless steel is effortlessly cleaned and maintained, guaranteeing the long-term preservation of their appealing appearance.

- Q: Are stainless steel sheets suitable for electrical enclosures?

- Yes, stainless steel sheets are suitable for electrical enclosures. Stainless steel is known for its excellent strength, corrosion resistance, and durability, making it an ideal material for protecting electrical components. It provides a high level of protection against environmental factors such as moisture, dust, and extreme temperatures. Additionally, stainless steel has good electrical conductivity, which is crucial for proper grounding and shielding. It also offers good electromagnetic compatibility (EMC), reducing the risk of electromagnetic interference (EMI) in sensitive electrical equipment. Moreover, stainless steel is easy to clean and maintain, ensuring a long-lasting and reliable enclosure for electrical applications.

- Q: What is the difference between stainless steel sheets and regular steel sheets?

- The composition and properties of stainless steel sheets and regular steel sheets are different. Stainless steel sheets are primarily made of iron and contain at least 10.5% chromium, which gives them their unique stainless properties. On the other hand, regular steel sheets are primarily made of iron and carbon, without any significant amount of chromium. The presence of chromium in stainless steel sheets provides several advantages. Firstly, it enhances the material's corrosion resistance, making it highly resistant to rust and staining. This makes stainless steel sheets suitable for applications in environments where moisture or exposure to corrosive substances is a concern, such as in the food and beverage industry or marine applications. Additionally, stainless steel sheets have excellent heat resistance, making them suitable for high-temperature applications. They can withstand extreme temperatures without losing their structural integrity, which may not be the case for regular steel sheets. The appearance of the two materials also differs. Stainless steel sheets have a bright, reflective surface due to their chromium content, giving them a lustrous and modern look. On the other hand, regular steel sheets have a duller and less polished appearance. Furthermore, stainless steel sheets are often more expensive than regular steel sheets due to additional manufacturing processes and the higher cost of the chromium alloy. However, the enhanced corrosion resistance and durability provided by stainless steel sheets can often justify the higher cost in various applications. In conclusion, stainless steel sheets differ from regular steel sheets in terms of composition, properties, appearance, and cost. Stainless steel sheets offer superior corrosion resistance, heat resistance, and a visually appealing surface, making them ideal for specific applications where these attributes are required. Regular steel sheets, on the other hand, are more affordable but lack the unique properties of stainless steel.

- Q: What is the thickness tolerance for stainless steel sheets?

- The thickness tolerance of stainless steel sheets can differ based on the particular grade and manufacturing method employed. Typically, the accepted thickness tolerance for stainless steel sheets in the industry spans from +/- 0.005 inches to +/- 0.010 inches. Nonetheless, it is essential to acknowledge that various manufacturers and suppliers may establish their own distinct tolerances. Thus, it is consistently recommended to consult the manufacturer's or supplier's specifications for precise information. Furthermore, certain applications or industries may impose stricter thickness tolerances, and it is imperative to comply with the specific requirements set forth by the customer or industry standards in such instances.

- Q: What's the difference between stainless steel coil and stainless steel plate?

- The chemical resistance of the medium (acid, alkali, salt and other chemical etching) corrosion of steel called acid resistant steel. Because of the difference in the chemical composition of the two, and make their corrosion resistance is different, ordinary stainless steel is generally not resistant to chemical medium corrosion, and acid resistant steel are generally stainless steel.

- Q: Can stainless steel sheets be used for elevator doors?

- Yes, stainless steel sheets can be used for elevator doors.

- Q: What are the different types of textured finishes available for stainless steel sheets?

- There are several different types of textured finishes available for stainless steel sheets, each offering a unique aesthetic appeal and functional benefits. Some of the most common textured finishes include: 1. Brushed Finish: This is the most widely used textured finish for stainless steel sheets. It is achieved through a process of brushing the surface with abrasive materials, creating a distinctive pattern of parallel lines. The brushed finish provides a smooth and elegant appearance while also masking scratches and fingerprints. 2. Embossed Finish: In this type of textured finish, a pattern is stamped onto the stainless steel sheet, creating a raised design. Embossed finishes can range from simple patterns like diamonds or squares to more complex designs. This finish adds depth and visual interest to the metal surface. 3. Bead Blast Finish: This finish is achieved by propelling fine glass beads or ceramic particles onto the stainless steel sheet at high pressure. It creates a uniform matte appearance with a slightly rough texture. Bead blasting is often used for decorative purposes, as it can give stainless steel a unique and contemporary look. 4. Linen Finish: Also known as a cross-hatch finish, the linen finish features a pattern of fine parallel lines that intersect, resembling the texture of linen fabric. This finish is achieved through a process of mechanical rolling or brushing. It provides a textured surface that is both visually appealing and resistant to scratches. 5. Satin Finish: Similar to brushed finish, the satin finish is achieved by brushing the stainless steel sheet with abrasive materials. However, the satin finish has a smoother appearance with a less pronounced pattern of parallel lines. It offers a subtle shine and a refined look, making it a popular choice for architectural and decorative applications. 6. Hammered Finish: This textured finish is created by pounding the stainless steel sheet with a ball-peen hammer or a similar tool. The result is a surface with a unique hammered pattern that adds a rustic and artisanal touch to the metal. Hammered finishes are commonly used in interior design and decorative applications. Overall, the choice of textured finish for stainless steel sheets depends on the desired aesthetic, functionality, and application. Each finish has its own distinct appearance and can enhance the visual appeal of stainless steel while also providing additional benefits such as scratch resistance and fingerprint hiding.

- Q: How do I determine the flatness of stainless steel sheets?

- To determine the flatness of stainless steel sheets, you can use various methods such as visual inspection, measuring with a straight edge or ruler, or utilizing specialized tools like a flatness gauge or a laser level. Visual inspection involves observing the surface for any visible curvature or warping. Measuring with a straight edge or ruler can help identify any gaps or deviations from a flat surface. Specialized tools like a flatness gauge or a laser level provide more precise measurements by quantifying the degree of flatness.

Send your message to us

Stainless Steel sheet 410 with No.4 Surface Treatment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords