Stainless Steel Sheet 2B NO.1 NO.4 finished

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Stainless Steel Sheet 2B NO.1 NO.4 finished

Product name | Price of 1kg stainless steel sheet |

Standard | ASTM, AISI, JIS, GB, DIN |

Mill | TISCO , LISCO, ZPSS, BAOSTEEL, SKS |

Certification | ISO Certificate, Mill Test Certificate |

MOQ | 1 Metric Ton |

Terms of delivery | FOB, CFR, CIF |

Time of shipment | Normally delivery within 10 days from stocks. |

Stocks | Ready In stocks |

Stainless Steel Sheet 2B NO.1 NO.4 finished

Chemical Composition | ||||

SS304 | SS 316 | SS430 | SS201 | |

Ni(%) | 8.0-10.5 | 10.0-14.0 | -- | 0.8-1.2 |

Cr(%) | 18.0-20 | 16.0-18.0 | 16.0-18.0 | ≤0.15 |

C(%) | ≤0.08 | ≤0.08 | ≤0.12% | ≥40 |

Elong(%) | ≥40 | ≥40 | ≥22 | |

Hardness | HB≤187,HRB≤90, HV≤200 | HB≤187, HRB≤90 HV≤200 | HB≤183, HRB≤88 HV≤200 | HB≤241,HRB≤100, HV≤240 |

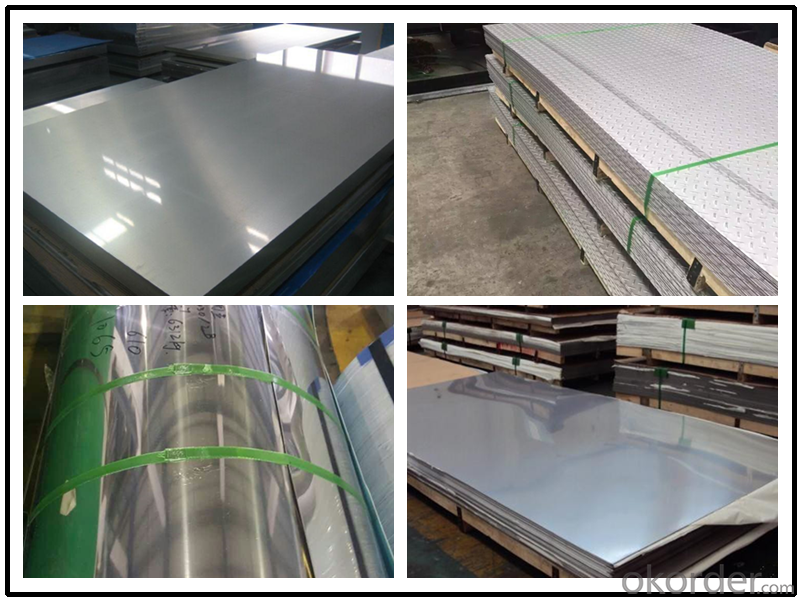

Stainless Steel Sheet Series

Stainless Steel Polished Sheet (8K Mirror, Hairline, Grit 240,320)

Embossed Stainless Steel Sheet

Etched Stainless Steel Sheet,

PVD Colored Stainless Steel Sheet,

Perforated Stainless Steel Plate

Chequered Stainless Steel Sheet

Stainless Steel Sheet 2B NO.1 NO.4 finished

Packaging & Shipping

ApplicationStainless Steel Sheet 2B NO.1 NO.4 finished

- Q: Can stainless steel sheets be used outdoors?

- Indeed, outdoors can accommodate the use of stainless steel sheets. Its exceptional resistance to corrosion renders it an impeccable option for outdoor purposes. The material can endure exposure to moisture, humidity, and even the harshest weather conditions without succumbing to rust or deterioration. Consequently, stainless steel sheets become fitting for an array of outdoor applications, including building facades, roofing, fencing, outdoor furniture, and decorative elements. Furthermore, stainless steel boasts durability, effortless maintenance, and an elegant aesthetic, solidifying its status as a widely favored choice for outdoor utilization in residential, commercial, and industrial environments.

- Q: Can stainless steel sheets be used for food processing or medical applications?

- Yes, stainless steel sheets can be used for food processing or medical applications. Stainless steel is a highly durable and corrosion-resistant material, making it an ideal choice for these industries where hygiene and cleanliness are of utmost importance. In food processing, stainless steel sheets are commonly used for various applications such as countertops, work surfaces, sinks, storage containers, and equipment. Its non-porous surface prevents the growth of bacteria and makes it easy to clean and sanitize. Similarly, in medical applications, stainless steel sheets are widely used due to their excellent resistance to corrosion, heat, and chemicals. They are used for medical instruments, surgical equipment, implants, and other medical devices that require high levels of cleanliness and sterilization. Stainless steel's biocompatibility and resistance to body fluids make it suitable for implantable devices like pacemakers, joint replacements, and dental implants. Overall, stainless steel sheets are a preferred choice for food processing and medical applications due to their hygienic properties, durability, and resistance to corrosion.

- Q: Are stainless steel sheets suitable for roofing applications?

- Yes, stainless steel sheets are suitable for roofing applications. Stainless steel is known for its durability, resistance to corrosion, and strength, making it an ideal material for roofs. It can withstand harsh weather conditions, including extreme temperatures, high winds, and heavy rainfall. Stainless steel sheets are also fire-resistant, which adds an extra layer of safety to the roof. Additionally, stainless steel has a long lifespan, requiring minimal maintenance and repairs. Overall, stainless steel sheets provide a reliable and long-lasting solution for roofing applications.

- Q: Can stainless steel sheets be used in industrial applications?

- Yes, stainless steel sheets can definitely be used in a wide range of industrial applications. Stainless steel is known for its excellent corrosion resistance, durability, and strength, making it ideal for various industrial environments. It is commonly used in sectors such as automotive, aerospace, construction, manufacturing, food and beverage, chemical processing, and many others. Stainless steel sheets are often used for their ability to withstand high temperatures, harsh chemicals, and extreme conditions. They can be fabricated into different shapes and sizes, making them suitable for a wide range of applications. Stainless steel sheets are commonly used for manufacturing equipment and machinery, storage tanks, pipelines, architectural structures, and as a protective layer on surfaces that require resistance to corrosion. Furthermore, stainless steel sheets offer hygienic properties, making them suitable for applications in the food and beverage industry. They are easy to clean, maintain, and sterilize, ensuring compliance with strict industry standards. In summary, stainless steel sheets are versatile and reliable materials that can be effectively used in various industrial applications due to their exceptional corrosion resistance, durability, strength, and hygienic properties.

- Q: How are stainless steel sheets made?

- Stainless steel sheets undergo a process called hot rolling to be produced. This starts by melting iron, nickel, chromium, and other elements in an electric arc furnace. The resulting mixture is then cast into large rectangular blocks known as slabs. The slabs are subjected to high temperatures and passed through a series of hot rolling mills. These mills consist of large rollers that gradually decrease the slab's thickness while increasing its length and width. As the slab goes through each rolling mill, it is constantly squeezed by the rollers, resulting in a thinner and longer sheet. Following the hot rolling process, the stainless steel sheet goes through annealing. This involves heating the sheet to a specific temperature and then allowing it to cool slowly. This process helps release internal stresses and enhance the material's mechanical properties. Next comes pickling, where the sheet is submerged in an acid solution to eliminate any surface impurities and oxides. This improves the appearance and corrosion resistance of the stainless steel. Once the pickling process is done, the sheet undergoes cold rolling. Cold rolling further decreases the sheet's thickness and improves its surface finish. This is done at room temperature, increasing the hardness and strength of the stainless steel. Lastly, the stainless steel sheet undergoes various finishing processes. These may include cutting to size, leveling, surface polishing, and coating to enhance appearance or protect against corrosion. In conclusion, the manufacturing process of stainless steel sheets involves a combination of melting, casting, hot rolling, annealing, pickling, cold rolling, and finishing processes. This ensures that the final product meets the desired specifications in terms of thickness, strength, and surface finish.

- Q: What is the thickness range available for stainless steel sheets?

- The thickness range available for stainless steel sheets typically varies from 0.4mm to 6mm, depending on the specific requirements and applications.

- Q: What are the advantages of using stainless steel sheets in the medical industry?

- There are several advantages of using stainless steel sheets in the medical industry: 1. Hygiene and Cleanliness: Stainless steel is a non-porous material, which makes it easy to clean and disinfect. It is resistant to bacteria, mold, and other pathogens, making it an ideal choice for medical equipment, surgical instruments, and even hospital furniture. 2. Durability and Longevity: Stainless steel is highly durable and can withstand harsh conditions, including high temperatures, humidity, and corrosive substances. This ensures that medical equipment and instruments made from stainless steel sheets have a longer lifespan, reducing the need for frequent replacements. 3. Strength and Safety: Stainless steel sheets offer excellent strength and structural integrity, making them suitable for applications that require resistance to impact and pressure. This is crucial in the medical industry, where instruments and equipment undergo constant use and handling. 4. Resistance to Stains and Corrosion: Stainless steel is highly resistant to stains and corrosion, even in aggressive environments. This property is essential in medical facilities where exposure to various chemicals and liquids is common. The resistance to corrosion ensures that stainless steel sheets remain intact and do not release harmful substances into the environment. 5. Aesthetic Appeal: Stainless steel sheets have a sleek and modern appearance that adds to the overall aesthetic appeal of medical equipment and instruments. This can create a positive impression on patients, instilling confidence in the quality and cleanliness of the medical facility. 6. Recyclability: Stainless steel is a sustainable material as it can be recycled without any loss in quality. This reduces the environmental impact of the medical industry by minimizing waste and conserving resources. In conclusion, the advantages of using stainless steel sheets in the medical industry include hygiene, durability, strength, resistance to stains and corrosion, aesthetic appeal, and recyclability. These qualities make stainless steel a reliable and cost-effective choice for medical equipment, instruments, and other applications in healthcare settings.

- Q: Are stainless steel sheets suitable for elevator floor panels?

- Yes, stainless steel sheets are suitable for elevator floor panels. Stainless steel is a durable and corrosion-resistant material that can withstand heavy foot traffic and frequent cleaning without losing its structural integrity. Additionally, its sleek and modern appearance makes it a popular choice for elevator interiors.

- Q: What is stainless steel AB board, please?

- Both 2B and BA can be polished into 8K mirror panels, but 2B requires more polishing steps, and the BA can only be polished to achieve the 8K effect. Depending on the end product, there is a difference in whether the BA is polished and some BA products do not need to be polished and used directly.

- Q: Can stainless steel sheets be used for signage or lettering?

- Yes, stainless steel sheets can be used for signage or lettering. Stainless steel is a highly durable and versatile material that is commonly used in various applications, including signage. It offers excellent resistance to corrosion, making it suitable for both indoor and outdoor use. Stainless steel sheets can be easily fabricated and cut into different shapes and sizes, allowing for the creation of customized signage and lettering designs. Additionally, stainless steel has a sleek and modern appearance, making it an attractive option for signage in commercial or professional settings. Overall, stainless steel sheets provide a reliable and long-lasting solution for signage and lettering needs.

Send your message to us

Stainless Steel Sheet 2B NO.1 NO.4 finished

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords