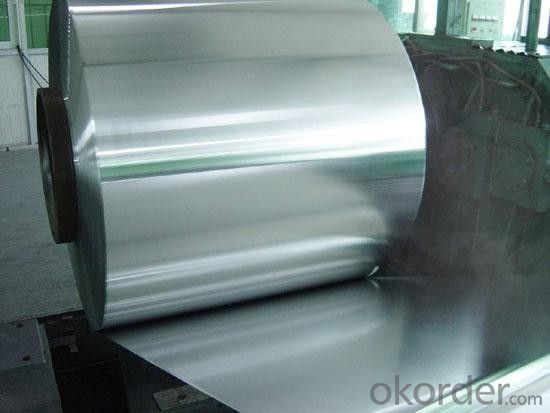

Stainless Steel Plate 430 with No.4 Surface Treatment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot sale stainless steel sheet 201/202/304/304l/310S/309S/316L/316Ti/316/316l/321,410/420/430/444/443/409L, and 904L.

Description of Stainless Steel Sheet:

Description | steel sheet,hot rolled steel sheet,cold rolled steel sheet, steel sheet,sheet,steel plate |

Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

Application | Steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

Packaging | Standard export sea-worthy packing |

Delivery time | 10-30 days |

Quality | No.1 |

Productivity | 500 tons/Day |

Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

Contacts | If you have any question,please feel free contact me. |

Stainless steel sheet surface finish characteristics

Surface finish | Characteristics and application |

2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

No.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

No.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

Main Features of stainless steel sheet :

•Escalator, Elevator, Doors

•Furniture

•Production tools, Kitchen appliances, freezers, cold rooms

•Auto Parts

•Machinery and Packaging

•Equipment and Medical devices

•Transport system

Product Details:

Sandard Seaworth Packing(wooden packing with water proof paper)

FAQ:

1. What's the quality?

very fine

2. How long get reply?

within 24 hours

If you have any question about stainless steel sheets,donot forget to sending the email to Us! You will get the competitive Price and have a very good experience about the Buying Process! CNBM International Corporation is always your trustful friend!

- Q: What is the yield strength of stainless steel sheets?

- The yield strength of stainless steel sheets varies depending on the grade and thickness of the sheet. Generally, it can range from 30,000 to 100,000 pounds per square inch (psi).

- Q: 904L stainless steel plate generally used in what industry is more?

- Super austenitic stainless steel (904L stainless steel) is a highly alloyed austenitic stainless steel carbon content is very low, in dilute sulphuric acid has good corrosion resistance for corrosion in harsh environmental conditions and design.

- Q: What is the maximum operating temperature for stainless steel sheets?

- The maximum operating temperature for stainless steel sheets typically ranges from 1500°F to 1650°F (815°C to 900°C), depending on the grade of stainless steel.

- Q: How do you prevent fingerprints or smudges on stainless steel sheets?

- To prevent fingerprints or smudges on stainless steel sheets, there are several effective measures you can take: 1. Clean with a microfiber cloth: Use a soft microfiber cloth to wipe down the stainless steel surface regularly. Microfiber is known for its ability to attract and trap dirt, dust, and oils without leaving streaks or smudges. 2. Use warm soapy water: Mix a small amount of mild dish soap with warm water and gently wipe the stainless steel surface with a soft cloth or sponge. Rinse thoroughly and dry with a clean towel. This method effectively removes grease, fingerprints, and smudges. 3. Invest in stainless steel cleaners: There are numerous stainless steel cleaning products available in the market. These cleaners are specifically formulated to remove fingerprints, smudges, and restore the shine of stainless steel surfaces. Follow the instructions on the product for best results. 4. Apply a protective coating: Consider using a stainless steel protective coating or sealant. These products create a thin, invisible barrier that helps repel fingerprints and smudges. Apply the coating according to the manufacturer's instructions and reapply as needed. 5. Avoid abrasive cleaners or tools: Abrasive cleaners, scrub brushes, steel wool, or harsh chemicals can damage the protective layer of stainless steel, making it more prone to fingerprints and smudges. Stick to non-abrasive cleaning methods and tools to maintain the integrity of the stainless steel surface. 6. Handle with care: When touching stainless steel sheets, try to handle them with clean hands or wear gloves to prevent the transfer of oils or dirt. Avoid dragging objects across the surface, as this can cause scratches and make it more susceptible to smudging. By incorporating these preventive measures into your cleaning routine and handling practices, you can effectively minimize fingerprints and smudges on your stainless steel sheets, keeping them looking clean and pristine.

- Q: Can stainless steel sheets be used for furniture or fixtures?

- Yes, stainless steel sheets can be used for furniture or fixtures. Stainless steel is a durable and versatile material that is resistant to corrosion, making it an excellent choice for furniture and fixtures that are exposed to moisture or high humidity. It can be used for a variety of applications such as tabletops, countertops, shelves, cabinets, and even decorative accents. Stainless steel sheets can be easily fabricated into different shapes and sizes, allowing for customization to suit specific design requirements. Additionally, stainless steel has a modern and sleek appearance, making it a popular choice for contemporary and industrial-style furniture and fixtures.

- Q: Can stainless steel sheets be used for HVAC systems?

- Yes, stainless steel sheets can be used for HVAC (heating, ventilation, and air conditioning) systems. Stainless steel is a popular material choice for HVAC systems due to its excellent corrosion resistance, durability, and ability to withstand high temperatures. It is commonly used in HVAC applications such as ductwork, vents, and heat exchangers. Stainless steel sheets provide a smooth and clean surface, which helps in maintaining good air quality by preventing the build-up of dust, dirt, and other contaminants. Additionally, stainless steel is easy to clean and maintain, making it a suitable choice for HVAC systems that require regular maintenance and cleaning.

- Q: Are stainless steel sheets resistant to caustic soda?

- Yes, stainless steel sheets are generally resistant to caustic soda.

- Q: What are the different types of stainless steel sheet finishes for automotive applications?

- Some of the different types of stainless steel sheet finishes for automotive applications include brushed, polished, satin, mirror, and textured finishes. These finishes vary in terms of appearance, texture, and level of reflectivity, providing options for various aesthetic preferences and functional requirements in the automotive industry.

- Q: Can stainless steel sheets be used for medical implant devices?

- Medical implant devices can utilize stainless steel sheets, as they possess excellent mechanical properties, corrosion resistance, and biocompatibility. Stainless steel is widely employed in the medical field due to its strength, durability, and ability to endure sterilization processes. Various medical implant devices, including plates, screws, and pins used in orthopedic surgeries, dental implants, cardiovascular devices, and other procedures, can be fabricated from stainless steel sheets. The high strength-to-weight ratio of stainless steel makes it suitable for applications requiring load-bearing capabilities, while its resistance to corrosion ensures longevity within the body. Moreover, stainless steel is a biocompatible material, meaning it is well-tolerated by the human body and does not cause adverse reactions or allergies. Techniques like passivation or coating can enhance the biocompatibility of stainless steel surfaces. It is vital to emphasize that selecting the appropriate stainless steel grade and surface finish is essential for medical implant devices to ensure compatibility with specific body tissues and environments. Thorough testing and regulatory approval are also necessary to guarantee the safety and effectiveness of stainless steel medical implant devices. To summarize, stainless steel sheets can indeed be utilized for medical implant devices due to their mechanical properties, corrosion resistance, and biocompatibility. Ensuring the suitability and safety of stainless steel implants in medical applications necessitates proper selection, testing, and regulatory approval.

- Q: What are the different types of embossed finishes available for stainless steel sheets?

- Stainless steel sheets come in a variety of embossed finishes, offering different looks and textures. Some popular options are: 1. Diamond pattern: This embossed finish adds a decorative touch with its raised diamond pattern. 2. Linen pattern: Resembling linen fabric, this textured finish adds depth and visual interest. 3. Leather pattern: Mimicking genuine leather, this embossed finish creates a stylish and unique textured surface. 4. Bead pattern: With its raised, rounded pattern resembling beads, this finish adds a subtle decorative element. 5. Checker pattern: Arranged in a checkerboard pattern, this embossed finish brings a modern and stylish look. 6. Hammered pattern: Resembling hammer marks, this textured finish adds a rustic and handcrafted aesthetic. These examples showcase the variety of embossed finishes available for stainless steel sheets. Each finish offers a distinct look and texture, allowing you to choose the one that best suits your design preferences and application requirements.

Send your message to us

Stainless Steel Plate 430 with No.4 Surface Treatment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords