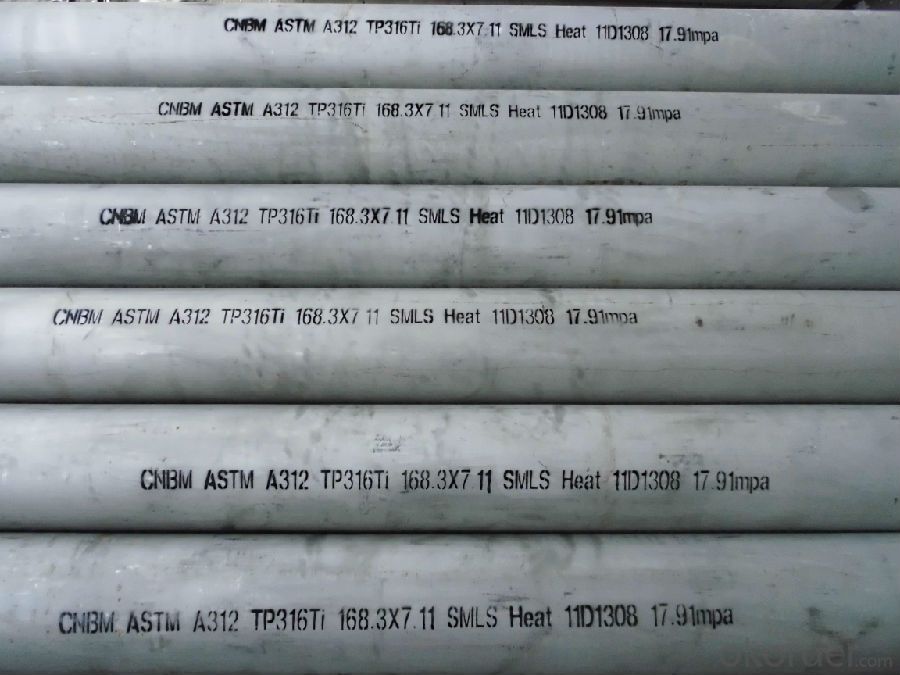

Stainless steel pipe 316Ti 7

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

316Ti stainless steel plate is the addition of Ti in SUS316 steel can improve the resistance to intergranular corrosion resistance.

The chemical composition of 316Ti stainless steel:

C (%): less than 0.08

Si (%): less than 1

Mn (%): less than 2

P (%) is less than or equal to: 0.045

S (%) is less than or equal to 0.03

Cr (%): 16 ~ 18

Ni (%): 10 ~ 14

Mo (%): 2 ~ 3

other (%):

5 (C+N) = Ti = 0.70, N = 0.10

The mechanical properties of 316Ti stainless steel:

YS (Mpa) = 205 TS (Mpa) = 520 EL (%) is more than or equal to 40 Hv 200 degrees

- Q: How do you join stainless steel pipes to other materials?

- Joining stainless steel pipes to other materials can be achieved through several methods, depending on the specific application and requirements. Here are a few common techniques used: 1. Welding: Welding is the most common and effective method for joining stainless steel pipes to other materials. Different types of welding processes such as TIG (Tungsten Inert Gas) welding, MIG (Metal Inert Gas) welding, or stick welding can be used, depending on the material being joined and the desired strength of the joint. Welding provides a strong and durable bond between stainless steel pipes and other materials. 2. Flanges: Flanges are commonly used to join stainless steel pipes to other materials in applications that require easy disassembly or connection to different equipment. Flanges are typically made from materials such as carbon steel, cast iron, or even stainless steel itself. The flanges are bolted together, creating a secure joint that can be easily disconnected when needed. 3. Threaded connections: Stainless steel pipes can also be joined to other materials using threaded connections. This method is often used for smaller diameter pipes or when the pipes need to be easily removed or replaced. The threaded connections can be made using pipe fittings such as couplings, unions, or adapters, which have male and female threads that screw together to form a tight seal. 4. Compression fittings: Compression fittings are another option for joining stainless steel pipes to other materials. These fittings consist of a compression nut, a ferrule, and a body that houses the ferrule. The ferrule is compressed onto the pipe, creating a tight seal when the compression nut is tightened. Compression fittings provide a reliable and leak-free joint between stainless steel pipes and other materials. 5. Mechanical connectors: In some cases, mechanical connectors can be used to join stainless steel pipes to other materials. These connectors typically involve clamping or fastening mechanisms that secure the pipes together without the need for welding or threading. Mechanical connectors can be a suitable option in situations where disassembly and reassembly are required. It is important to consider the specific application, material compatibility, and the required strength and durability of the joint when selecting the appropriate method to join stainless steel pipes to other materials. Consulting with a professional or referring to industry standards and guidelines is recommended to ensure a proper and reliable connection.

- Q: What are the different types of stainless steel pipe couplings?

- In the market, one can find a variety of stainless steel pipe couplings, each offering their own unique features and functions. Some commonly used types are as follows: 1. Compression couplings: These couplings are designed to securely connect pipes by compressing their ends together using a compression nut. They are suitable for both rigid and flexible pipe systems and can be easily installed. 2. Flanged couplings: These couplings have flanges on both ends, which can be bolted together to create a strong and leak-proof connection. They are commonly used in industrial applications that involve high pressures and temperatures. 3. Grooved couplings: These couplings consist of two segments that grip the pipe ends when tightened, creating a reliable and flexible connection. They are frequently used in fire protection systems and HVAC applications, as they are easy to install and can withstand vibration and movement. 4. Threaded couplings: These couplings have internal threads that allow them to be screwed onto the pipe ends. They are commonly used in low-pressure applications and can be easily assembled and disassembled. 5. Quick connect couplings: These couplings have a quick-connect mechanism that enables easy and rapid installation without the need for tools or additional components. They are commonly used in plumbing and irrigation systems. 6. Welded couplings: These couplings require welding the pipe ends together to create a permanent and strong connection. They are commonly used in high-pressure and high-temperature applications where a robust joint is essential. To ensure the appropriate selection of a stainless steel pipe coupling, it is important to consider the specific requirements of the application, such as operating conditions, pipe material, and system design. Seeking advice from a professional or referring to industry standards can help in making the right choice.

- Q: How do you calculate the pipe length required for a specific application?

- To determine the required length of a pipe for a specific application, several considerations must be taken into account. 1. Flow Rate: The desired flow rate or volume of fluid to be transported through the pipe per unit of time needs to be established. This can be measured in various units such as gallons per minute (GPM) or liters per second (L/s). 2. Pipe Material: The material of the pipe to be used for the application should be identified. Different materials have varying friction coefficients, which impact the overall length required. 3. Friction Loss: The friction loss in the pipe must be calculated based on the flow rate and material properties. This involves determining the friction factor specific to the pipe material and utilizing the appropriate equation, such as the Darcy-Weisbach equation or Hazen-Williams equation, to compute the friction loss. 4. Pressure Drop: The desired pressure drop across the pipe needs to be taken into consideration. Application requirements or system design typically specify this. The pressure drop can be determined using the Bernoulli's equation or other relevant equations. 5. Pipe Diameter: The appropriate pipe diameter should be determined based on the desired flow rate and allowable pressure drop. Pipe sizing charts or equations tailored to the pipe material and flow characteristics can be utilized for this purpose. 6. Calculation of Pipe Length: Once the pipe diameter is known, the required length can be calculated based on the desired flow rate, pressure drop, and friction loss. Pipe sizing equations or software tools specific to the pipe material can be employed for this calculation. 7. Additional Factors: Any additional factors that may impact the pipe length calculation, such as elevation changes, fittings, valves, or other system components, need to be considered. These factors may introduce additional friction losses or pressure drops that must be accounted for. It is important to note that pipe length calculations are typically performed by engineers or professionals with expertise in fluid mechanics and pipe system design. Consulting relevant codes, standards, and guidelines specific to the application is also recommended to ensure compliance with safety and performance requirements.

- Q: Can stainless steel pipes be used for cryogenic storage tanks?

- Yes, stainless steel pipes can be used for cryogenic storage tanks. Stainless steel is known for its high strength, corrosion resistance, and low thermal conductivity, making it suitable for handling extremely low temperatures required for cryogenic storage.

- Q: How do you prevent pressure loss in stainless steel pipes?

- To prevent pressure loss in stainless steel pipes, one can take several important steps: 1. Ensure proper pipe sizing: It is crucial to choose the appropriate diameter for the stainless steel pipe based on the system's flow rate and pressure requirements. Using pipes that are too small can result in increased pressure loss due to higher fluid velocities. 2. Reduce pipe length and bends: It is advisable to keep the stainless steel pipe as short as possible and minimize the number of bends or elbows. Lengthy pipes and multiple bends introduce friction and turbulence, which lead to pressure loss. 3. Opt for a smooth interior surface: Select stainless steel pipes with a smooth interior surface finish. This helps minimize pressure loss by reducing frictional resistance and turbulence. 4. Minimize unnecessary fittings and valves: Each fitting or valve in a stainless steel pipe system adds additional pressure loss. To maintain pressure, it is best to minimize the use of unnecessary fittings and valves, selecting those with low resistance instead. 5. Ensure proper installation: Correctly installing stainless steel pipes with proper alignment and support is crucial. Misaligned or poorly supported pipes can cause excessive stress and potential deformation, resulting in pressure loss. 6. Regular maintenance and cleaning: Periodically inspect and clean the stainless steel pipes to remove any accumulated scale, debris, or deposits. These obstructions can restrict flow and lead to pressure loss. 7. Consider flow control devices: Depending on the application, incorporating flow control devices such as flow restrictors, pressure regulators, or flow meters can help maintain optimal pressure levels in the stainless steel pipe system. By implementing these measures, one can minimize pressure loss in stainless steel pipes, ensuring efficient and effective fluid transportation within the system.

- Q: What is the difference between seamless and cold-rolled stainless steel pipes?

- Differences can be observed between seamless and cold-rolled stainless steel pipes in terms of their manufacturing process and resulting characteristics. Seamless stainless steel pipes are created by piercing a solid cylindrical billet of stainless steel and subjecting it to various steps, including elongation and reduction, to achieve the desired size and shape. Through this process, the pipe acquires a smooth and even surface without any welded seams. As a result, seamless stainless steel pipes exhibit superior strength, durability, and resistance to corrosion. Furthermore, they are capable of withstanding high pressure and temperature conditions, making them suitable for a wide range of applications, such as oil and gas pipelines, chemical processing, and power generation. On the other hand, cold-rolled stainless steel pipes are manufactured by rolling stainless steel sheets or strips at room temperature. This process involves passing the material through a series of rollers to reduce its thickness and shape it into a cylindrical form. Unlike seamless pipes, cold-rolled pipes possess visible welded seams on their surface. While these seams may potentially weaken the pipe, their strength and integrity can be improved by applying additional processes such as heat treatment or cold working. The choice between seamless and cold-rolled stainless steel pipes depends on the specific requirements of the application. Seamless pipes are generally preferred when high strength, corrosion resistance, and pressure resistance are crucial, especially in industries where leaks or failure can have severe consequences. On the other hand, cold-rolled pipes may be more suitable for applications where cost-effectiveness and moderate performance are sufficient, such as certain plumbing systems or decorative purposes. To summarize, seamless stainless steel pipes are manufactured without welded seams, offering superior strength, durability, and resistance to corrosion, making them ideal for demanding applications. Meanwhile, cold-rolled stainless steel pipes, which possess visible welded seams, are generally more cost-effective and suitable for less demanding applications that do not require the same level of strength and corrosion resistance.

- Q: Can stainless steel pipes be used for agricultural irrigation systems?

- Yes, stainless steel pipes can be used for agricultural irrigation systems. Stainless steel is known for its durability, corrosion resistance, and ability to withstand harsh environmental conditions, making it a suitable choice for agricultural applications where long-term performance is required.

- Q: Can stainless steel pipes be insulated with polyethylene-terephthalate glycol?

- No, stainless steel pipes cannot be insulated with polyethylene-terephthalate glycol.

- Q: Are stainless steel pipes suitable for abrasive media?

- Indeed, abrasive media finds stainless steel pipes to be a fitting option. Renowned for its impressive strength and resistance to corrosion, stainless steel proves to be an ideal material for managing abrasive substances. The sleek surface of stainless steel pipes aids in diminishing friction and lessening the damage caused by abrasive particles. Moreover, stainless steel pipes exhibit the ability to endure elevated pressures and temperatures, rendering them suitable for diverse industrial functions encompassing abrasive media, such as mining, chemical processing, and wastewater treatment. In summary, stainless steel pipes stand as a dependable and enduring selection for the transportation of abrasive media.

- Q: What are the different grades of stainless steel used for pipes?

- Pipes commonly utilize various grades of stainless steel, each possessing unique properties and characteristics. The following are some of the most frequently employed grades: 1. Grade 304: Widely utilized, this stainless steel grade offers exceptional corrosion resistance, high-temperature strength, and satisfactory formability. It finds common use in both indoor and outdoor applications, including water supply pipes, food processing equipment, and architectural structures. 2. Grade 316: Similar to Grade 304, this grade contains a higher molybdenum content, enhancing its resistance to corrosion, particularly against chlorides and other corrosive substances. It is commonly employed in marine environments, chemical processing plants, and medical equipment. 3. Grade 321: This grade contains titanium, which stabilizes it against sensitization during welding or high-temperature exposure. Notably, it exhibits exceptional oxidation resistance and is suitable for applications involving high temperatures, such as exhaust systems and boilers. 4. Grade 409: Due to its outstanding heat resistance and durability, this grade is frequently employed in automotive exhaust systems. Additionally, it demonstrates resistance to corrosion caused by road salts and other harsh chemicals. 5. Grade 347: Similar to Grade 321, this grade incorporates niobium, providing further stabilization against sensitization. It is commonly utilized in high-temperature applications that necessitate resistance to intergranular corrosion, such as aircraft and jet engine components. These examples merely scratch the surface of the multitude of stainless steel grades utilized in pipe manufacturing. The selection of a specific grade for a given application depends on various factors, including the environment, temperature, corrosion resistance requirements, and necessary mechanical properties.

Send your message to us

Stainless steel pipe 316Ti 7

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords