AISI 316L Welded/Seamless Stainless Steel Pipe

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 6 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Products information

Name | AISI 316L welded/seamless stainless steel pipe |

Standard | GB,JIS,DIN,EN,ASTM A554, A249, A269,A312,A213 and A270 |

Material Grade | 201: Ni 0.8%~1% |

202: Ni 3.5%~4.5% | |

304: Ni 8%, Cr 18% | |

316: Ni 10%, Cr 18% | |

316L: Ni10%~14% | |

310S:Ni19%-22% | |

Outer Diameter | 5-600mm |

Thickness | 0.3-100mm |

Length | 6m or as customers' request |

Tolerance | a) Outer Diameter: +/- 0.2mm |

b) Thickness: +/- 0.02mm | |

c) Length: +/- 5mm | |

Surface | 180G, 240G, 320G Satin / Hairline 400G, 600G Mirror finish,matte |

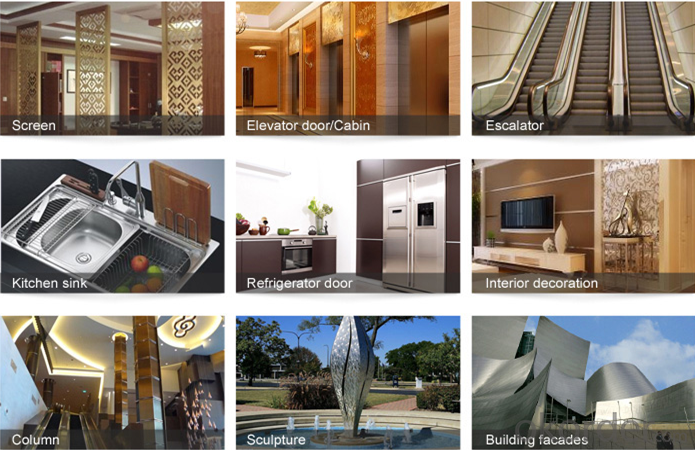

Application | handrail, railing, staircase, weld mesh screen, door, window, balcony, fence, bench, furniture, etc |

Test | Squash test, extended test, water pressure test, crystal rot test, heat treatment, NDT |

Picture--aisi 316l stainless steel pipe

Physical properties:

---aisi 316l stainless steel pipe/tube Feature

A) cold-rolled product appearance, good gloss, beautiful;

2) the addition of Mo, corrosion resistance, especially resistance to pitting corrosion;

3) excellent high temperature strength

4) Excellent hardening (after processing weakly magnetic)

5) solid solution state non-magnetic;

6) relative to 304 stainless steel, and higher prices.

Chemical composition

---aisi 316l stainless steel pipe

Stainless Steel tube/pipe grade | |||||||

Grade | Chemical composition | ||||||

C≤ | Si≤ | Mn≤ | P≤ | S≤ | Ni | Cr | |

201 | 0.15 | 1.00 | 5.5-7.5 | 0.5 | 0.03 | 3.50-5.50 | 16.00-18.00 |

202 | 0.15 | 1.00 | 7.5-10.0 | 0.5 | 0.03 | 4.00-6.00 | 17.00-19.00 |

304 | 0.08 | 1.00 | 2.00 | 0.045 | 0.03 | 8.00-11.00 | 18.00-20.00 |

304L | 0.03 | 1.00 | 2.00 | 0.045 | 0.03 | 8.00-12.00 | 18.00-20.00 |

309 | 0.2 | 1.00 | 2.00 | 0.04 | 0.03 | 12.00-15.00 | 22.00-24.00 |

309S | 0.08 | 1.00 | 2.00 | 0.045 | 0.03 | 12.00-15.00 | 22.00-24.00 |

310 | 0.25 | 1.50 | 2.00 | 0.04 | 0.03 | 19.00-22.00 | 24.00-26.00 |

310S | 0.08 | 1.00 | 2.00 | 0.045 | 0.03 | 19.00-22.00 | 24.00-26.00 |

316 | 0.08 | 1.00 | 2.00 | 0.045 | 0.03 | 10.00-14.00 | 16.00-18.00 |

316L | 0.03 | 1.00 | 2.00 | 0.045 | 0.03 | 10.00-14.00 | 16.00-18.00 |

316Ti | 0.08 | 1.00 | 2.00 | 0.045 | 0.03 | 10.00-14.00 | 16.00-18.00 |

2205 | 0.03 | 1.00 | 2.00 | 0.03 | 0.02 | 4.50-6.50 | 22.00-23.00 |

410 | 0.15 | 1.00 | 1.00 | 0.04 | 0.03 | 0.6 | 11.50-13.50 |

430 | 0.12 | 0.12 | 1.00 | 0.04 | 0.03 | 0.6 | 16.00-18.00 |

Application

---aisi 316l stainless steel pipe

The main applications include:

1.Petro-Chemical industry Onshore and offshore oil and gas industry

2.Power generation (Thermal and Nuclear)

3.Chemical industry

4.Ship building industry

5.Pulp & paper industry

6.Automotive industry

7.Pharmaceutical industry

8.Food industry

9.Equipment manufacturers (heat exchanger,boiler, condenser,feedwater heater,evaporator

- Q: Can stainless steel pipes be used for wastewater treatment systems?

- Yes, stainless steel pipes can be used for wastewater treatment systems. Stainless steel is highly resistant to corrosion, making it a suitable material for handling corrosive wastewater. It is also durable, long-lasting, and easy to maintain, making it an ideal choice for wastewater treatment systems.

- Q: What brand of stainless steel pipe cutting machine is good?

- Stainless steel cutting pipe should take into account the cutting speed, accuracy, cross section flatness, surface scratches, cutting tool loss and so on

- Q: Can stainless steel pipes be used for pulp and paper mills?

- Pulp and paper mills can indeed utilize stainless steel pipes. Stainless steel possesses outstanding resistance against corrosion, as well as remarkable strength and durability. Consequently, it becomes an optimal selection for piping systems operating in harsh environments such as pulp and paper mills. The conventional pipes tend to deteriorate due to the acidic and corrosive properties of the chemicals employed in the paper-making process; however, stainless steel pipes can withstand these conditions without compromising their structural integrity. Furthermore, stainless steel pipes are easily cleanable and maintainable, which proves to be vital in industries where hygiene holds utmost significance. Thus, stainless steel pipes emerge as a dependable and long-lasting solution for fulfilling the piping requirements of pulp and paper mills.

- Q: What are the common types of fittings used with stainless steel pipes?

- The common types of fittings used with stainless steel pipes include butt-weld fittings, socket-weld fittings, threaded fittings, and compression fittings. These fittings ensure secure connections between stainless steel pipes, allowing for efficient and reliable fluid or gas flow.

- Q: What are the weld sleeves for stainless steel pipes?

- Quota refers to the quantity standard of manpower, material resources, financial resources and time consumed by qualified units under certain technical and organizational conditions. In the labor organization reasonable and rational use of materials and machinery under the condition of a predetermined number of resources consumed by the completed units qualified product standards, the level of social productive forces, it reflects the level of a certain period of time. For each construction project, the amount of labor is calculated, including basic labor and other labor. Plus the materials for this project, including basic materials and other materials. The unit price is based on the labor value of the different types of work at that time. The value of the material is the budgeted price based on the previous market price.

- Q: What is the maximum pressure rating for stainless steel pipe fittings?

- The maximum pressure rating for stainless steel pipe fittings varies depending on factors such as the size, type, and wall thickness of the fittings. It is important to refer to the manufacturer's specifications for accurate and specific pressure ratings for each stainless steel pipe fitting.

- Q: Are stainless steel pipes suitable for chemical storage tanks?

- Yes, stainless steel pipes are suitable for chemical storage tanks. Stainless steel is highly resistant to corrosion, making it an ideal choice for storing and transporting chemicals. It can withstand exposure to various chemicals, acids, and alkalis without deteriorating or contaminating the stored substances. Additionally, stainless steel pipes have high tensile strength and can withstand high pressure, making them a reliable option for chemical storage tanks that require durability and safety.

- Q: What is the difference between polished and unpolished stainless steel pipes?

- The primary distinction between polished and unpolished stainless steel pipes lies in their appearance and surface finish. Polished stainless steel pipes have undergone a polishing procedure, which enhances their visual appeal by creating a sleek, glossy, and reflective surface. This procedure involves the use of abrasive materials or compounds to eliminate any imperfections, scratches, or flaws on the stainless steel surface. On the contrary, unpolished stainless steel pipes possess a rougher, less lustrous, and more industrial-looking surface. They have not undergone the polishing process and therefore maintain their original surface finish, which may have slight imperfections, scratches, or a matte appearance. The choice between polished and unpolished stainless steel pipes depends on the desired application and aesthetic preference. Polished stainless steel pipes are commonly utilized in industries such as architecture, interior design, and food processing, where a visually pleasing and hygienic surface is necessary. Conversely, unpolished stainless steel pipes are frequently employed in applications where appearance is not a priority, such as industrial or structural uses. It is important to note that the performance and durability of both polished and unpolished stainless steel pipes are comparable, as the polishing process does not impact the inherent corrosion resistance and strength of the stainless steel material. Ultimately, the decision between polished and unpolished stainless steel pipes is based on the specific requirements and intended use of the pipes.

- Q: How do stainless steel pipes differ from other types of pipes?

- Stainless steel pipes differ from other types of pipes primarily due to their corrosion-resistant properties, which make them highly durable and long-lasting. Unlike other pipes, stainless steel pipes are less prone to rusting or corroding, making them suitable for a wide range of applications, particularly in industries where hygiene and cleanliness are essential. Additionally, stainless steel pipes have high strength and heat resistance, making them capable of withstanding extreme temperatures and pressures, making them a preferred choice for various industrial and commercial applications.

- Q: Can stainless steel pipes be insulated with ceramic?

- Yes, stainless steel pipes can be insulated with ceramic. Ceramic insulation is commonly used in industrial applications where high temperatures are involved. Ceramic insulation provides excellent heat resistance and thermal insulation properties. It can withstand extreme temperatures and is highly effective in reducing heat transfer. Ceramic insulation is often used to insulate pipes, tanks, furnaces, and other equipment in various industries. When applied to stainless steel pipes, ceramic insulation helps to maintain the temperature of the fluid inside the pipes and prevents heat loss or gain. It also provides protection against corrosion and mechanical damage. Overall, ceramic insulation is a suitable option for insulating stainless steel pipes in a wide range of applications.

Send your message to us

AISI 316L Welded/Seamless Stainless Steel Pipe

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 6 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords