Stainless Steel in Hot Rolled,Stainless Steel Coils 316,Stainless Steel Coils 316L from China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

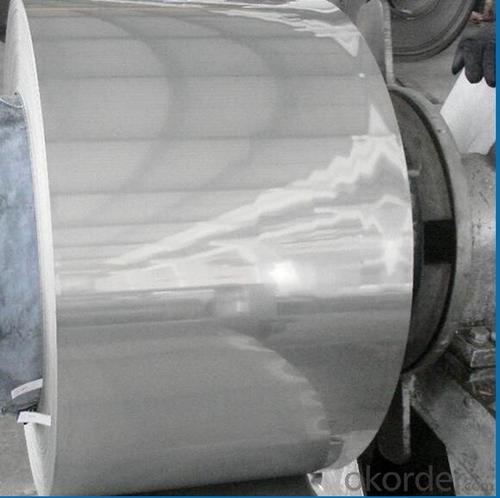

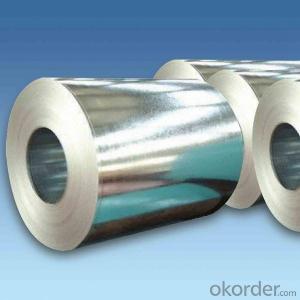

Hot Rolled Stainless Steel,Stainless Steel Coils 316,

Stainless Steel Coils 316L from China

Products Description

Product | stainless steel coils/plates/sheets | ||

Discharge Port | Any Port, China | ||

Size | Coils | Cold Rolled: | Thickness0.3-8mm,Width:280-2100mm |

Hot Rolled : | Thickness3-14mm,Width:650-2100mm | ||

Plates | Thickness2-80mm,Width:1500-3000mm | ||

Coil Weight | About 20 Tons | ||

Grade | 201,202,304/304L/304H,316/316L/316H,321/H,310S,409/L,430 etc. | ||

Technique | Hot Rolled/Cold Rolled | ||

Finish | 2B, BA, 2D, No1, No2, No4,NO.8,SB etc | ||

Edge | Mill Edge / Slitting Edge | ||

Package | In bundles, or as customer's requirement | ||

Place of Origin | Made in China | ||

MOQ | 20 Tons | ||

Packaging & Delivery

Packaging Detail Standard export packing or following customer's demand

Delivery Time: Within 15-20 days after deposit or according to the order quantity

Detail picture of Products:

Application

boiler heat exchanger, machinery andpetroleum ,chemical industries, hardware fields,Food industry,construction material,kitchen utensils, building construction, medical equipment,chemical tank, pipe etc

- Q: What are the pricing options for stainless steel sheets?

- The pricing of stainless steel sheets can vary depending on a range of factors. First and foremost, the grade of stainless steel used plays a significant role. Stainless steel is available in various grades, each offering different levels of corrosion resistance and durability. Higher-grade stainless steel sheets generally come at a higher price. Another factor that influences pricing is the thickness and size of the sheets. Thicker and larger stainless steel sheets tend to be more expensive due to the increased amount of raw material required and the additional processing involved. Moreover, the finish of the stainless steel sheets can also impact the pricing. Different finishes, such as brushed, mirror, or matte, are available for stainless steel sheets. Finishes that necessitate more extensive processing and polishing may come at a higher cost. Additionally, market conditions, including the supply and demand for stainless steel, can affect pricing. Prices can fluctuate based on factors such as raw material costs, production capacity, and global economic conditions. Furthermore, it is crucial to consider the supplier or manufacturer from whom you are purchasing the stainless steel sheets. Different suppliers may offer varying pricing options based on their overhead costs, production capabilities, and market positioning. To summarize, the pricing options for stainless steel sheets are influenced by factors such as grade, thickness, size, finish, market conditions, and the supplier. It is advisable to conduct thorough research and compare prices from different sources to find the most suitable option for your specific requirements.

- Q: Can stainless steel sheets be used for outdoor applications?

- Yes, stainless steel sheets can be used for outdoor applications. Stainless steel is highly resistant to corrosion, making it ideal for outdoor use where it will be exposed to moisture and other environmental factors. It is commonly used for outdoor structures, architectural elements, and equipment in industries such as construction, transportation, and marine.

- Q: Are stainless steel sheets suitable for food processing applications?

- Yes, stainless steel sheets are highly suitable for food processing applications. Stainless steel is known for its excellent corrosion resistance, hygienic properties, and resistance to high temperatures, making it ideal for use in the food industry. It is easy to clean, does not react with food, and is resistant to bacterial growth, ensuring food safety and quality.

- Q: What is the width of the carbon steel coil and the width of the stainless steel coil, one is 1250, and the other is 1219?

- Domestic stainless steel rolling mill is generally 1219, but the design standard is 1300, so there will be flash board 1250, that is not the standard board, belonging to the flash, waste materials, many products manufacturers are also in 1219 as a reference size, product development, if the plate width will be wasted, a lot of scrap production the process, so the business order is generally around 1219 stainless steel coil.

- Q: What is the fire rating of stainless steel sheets?

- The fire rating of stainless steel sheets is typically determined based on their thickness and the specific grade of stainless steel employed. Stainless steel possesses inherent fire-resistant characteristics, as it does not readily melt, ignite, or aid in the propagation of flames. Nonetheless, the fire rating might differ depending on the intended use and the regulatory standards adhered to. Generally speaking, stainless steel sheets are regarded as possessing commendable fire resistance. However, if a precise fire rating is necessary, it is advisable to seek guidance from the manufacturer or a fire protection engineer for more precise information.

- Q: What is the tensile strength of stainless steel sheets?

- The tensile strength of stainless steel sheets varies depending on the specific grade and thickness of the material. Generally, stainless steel sheets have a high tensile strength compared to other materials. For example, common grades such as 304 and 316 stainless steel sheets typically have tensile strengths ranging from 515 to 690 megapascals (MPa) or 74,800 to 100,000 pounds per square inch (psi). However, it is important to note that different grades and thicknesses of stainless steel sheets may have different tensile strength values. It is always recommended to consult the manufacturer or supplier for precise information on the tensile strength of specific stainless steel sheets.

- Q: Are stainless steel sheets safe for contact with food?

- Yes, stainless steel sheets are safe for contact with food. Stainless steel is a non-reactive and non-toxic material, making it an excellent choice for food preparation and storage. It does not leach any harmful chemicals or flavors into the food and is resistant to corrosion, ensuring hygiene and safety.

- Q: Can stainless steel sheets be used for marine propellers?

- Yes, stainless steel sheets can be used for marine propellers. Stainless steel is known for its corrosion resistance and durability, making it suitable for marine applications. Its strength and resistance to saltwater corrosion make it a popular choice for manufacturing marine propellers.

- Q: What are the different shapes available for stainless steel sheets?

- There are several different shapes available for stainless steel sheets, depending on the specific requirements and applications. Some of the most common shapes include: 1. Rectangular sheets: These are the most commonly used shape for stainless steel sheets. They come in various standard sizes and can be easily cut to the desired dimensions. 2. Round sheets: Round stainless steel sheets are often used for decorative purposes or in applications where a seamless or curved surface is desired. They are available in different diameters and thicknesses. 3. Square sheets: Similar to rectangular sheets, square stainless steel sheets are used in a variety of applications. They provide a symmetrical and uniform appearance and can be easily cut to size. 4. Perforated sheets: These sheets have small holes punched through them in a regular pattern. They are commonly used in architectural and industrial applications where ventilation, filtration, or visibility is required. 5. Embossed sheets: Embossed stainless steel sheets have raised or recessed patterns on their surface, adding texture and visual interest. They are often used in interior design, furniture manufacturing, and automotive applications. 6. Expanded metal sheets: These sheets are made by cutting and stretching a solid sheet of stainless steel, creating a grid-like pattern with diamond-shaped openings. They are commonly used for security fencing, walkways, and industrial applications. 7. Checker plate sheets: Also known as tread plate or diamond plate, these sheets have a raised diamond pattern on the surface. They are commonly used for slip-resistant flooring, stair treads, and decorative accents. These are just a few examples of the different shapes available for stainless steel sheets. The choice of shape depends on the specific application, aesthetic preferences, and functional requirements of the project.

- Q: Are stainless steel sheets suitable for outdoor sculptures or artwork?

- Yes, stainless steel sheets are highly suitable for outdoor sculptures or artwork. Stainless steel is known for its durability, corrosion resistance, and ability to withstand harsh weather conditions. It can maintain its appearance and integrity even when exposed to rain, sun, and other environmental factors. Additionally, stainless steel offers a sleek and modern aesthetic, making it a popular choice for outdoor sculptures or artwork.

Send your message to us

Stainless Steel in Hot Rolled,Stainless Steel Coils 316,Stainless Steel Coils 316L from China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords