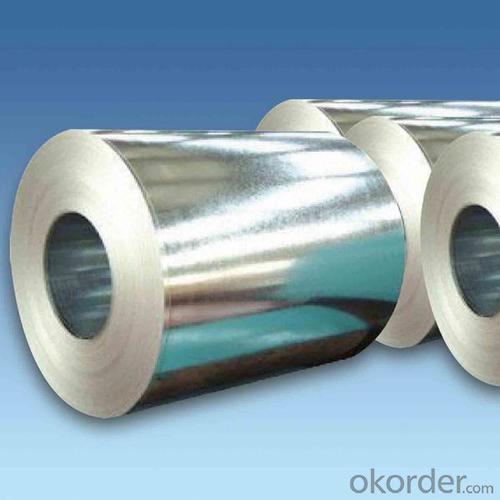

Stainless Steel Coils Hot Rolled NO.1 304 304L 316 316L Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Products Description for Stainless Steel Coils/Sheets:

Product | stainless steel coils/plates/sheets | ||

Discharge Port | Any Port, China | ||

Size | Coils | Cold Rolled: | Thickness0.3-8mm,Width:280-2100mm |

Hot Rolled : | Thickness3-14mm,Width:650-2100mm | ||

Plates | Thickness2-80mm,Width:1500-3000mm | ||

Coil Weight | About 20 Tons | ||

Grade | 201,202,304/304L/304H,316/316L/316H,321/H,310S,409/L,430 etc. | ||

Technique | Hot Rolled/Cold Rolled | ||

Finish | 2B, BA, 2D, No1, No2, No4,NO.8,SB etc | ||

Edge | Mill Edge / Slitting Edge | ||

Package | In bundles, or as customer's requirement | ||

Place of Origin | Made in China | ||

MOQ | 20 Tons | ||

Specifications for Stainless Steel Coils/Sheets:

Grade | C ≤ | Si ≤ | Mn ≤ | P ≤ | S ≤ | Ni ≤ | Cr ≤ |

201 | 0.12 | 0.75 | 7.00 | 0.045 | 0.045 | 1.00-1.28 | 13.70-15.70 |

202 | 0.15 | 1.00 | 2.25 | 0.045 | 0.045 | 4.07-4.17 | 14.00-16.00 |

304 | 0.08 | 0.75 | 2.00 | 0.045 | 0.03 | 8.00-11.00 | 18.00-20.00 |

304L | 0.035 | 0.75 | 2.00 | 0.045 | 0.03 | 8.00-13.00 | 18.00-20.00 |

309 | 0.15 | 0.75 | 2.00 | 0.045 | 0.03 | 12.00-15.00 | 22.00-24.00 |

310S | 0.08 | 1.50 | 2.00 | 0.045 | 0.03 | 19.00-22.00 | 24.00-26.00 |

316 | 0.08 | 1.00 | 2.00 | 0.045 | 0.03 | 10.00-14.00 | 16.00-18.00 |

316L | 0.035 | 0.75 | 2.00 | 0.045 | 0.03 | 10.00-15.00 | 16.00-18.00 |

321 | 0.04-0.10 | 0.75 | 2.00 | 0.045 | 0.03 | 9.00-13.00 | 17.00-20.00 |

405 | 0.08 | 0.75 | 1.00 | 0.045 | 0.03 | 0.06 | 11.5-13.5 |

409 | 0.089 | 1.00 | 1.00 | 0.045 | 0.05 | 0.06 | 10.50-11.75 |

410 | 0.15 | 0.75 | 1.00 | 0.045 | 0.03 | 0.06 | 11.5-13.5 |

420 | 0.16-0.25 | 1.00 | 1.00 | 0.040 | 0.03 | 0.06 | 12.00-14.00 |

430 | 0.12 | 0.75 | 1.00 | 0.045 | 0.03 | 0.06 | 16.00-18.00 |

Features of Stainless Steel Coils

(1)Good ductility

(2)Good corrosion resistance

(3)Excellent abrasion resistance and fatigue strength

(4)Good weldability

(5)Oxidation resistant performance

(6)Excellent in high temperature

Detail picture for Stainless Steel Coils/Sheets

FAQ for Stainless Steel Coils/Sheets:

Q: How can I get the samples?

A: If you need some samples to test ,please pay for the transportation freight of samples and our samples are free for you.

Q: How can I get your price list?

A: Please send us your email or fax and order information – Quantity, Specification (steel type, thickness, width, surface finish), then I can send you the price list.

FAQ for Stainless Steel Coils/Sheets:

Q:How to order?

A: Please send us your purchase order by email or fax .or you can ask us to send you a proforma invoice for your order .We need to know the following information for your order.

1) Shipping information-company name, street address, phone number, fax number, destination sea port

2) Product information – Quantity, Specification (steel type, thickness, width, surface finish)

3) Delivery time required

4) Forwarder's contact details if there's any in China

- Q: How do you prevent warping of stainless steel sheets?

- To prevent warping of stainless steel sheets, there are several measures that can be taken: 1. Proper storage and handling: Stainless steel sheets should be stored in a clean and dry environment, away from any sources of moisture or excessive heat. It is important to handle the sheets with care, avoiding any unnecessary bending or pressure that could lead to warping. 2. Correct welding techniques: When welding stainless steel sheets, it is crucial to use the appropriate techniques and procedures. Proper heat control and weld placement can help minimize the risk of warping. Preheating the sheets before welding can also help prevent distortion. 3. Stress relieving: This process involves heating the stainless steel sheets to a specific temperature and then cooling them slowly. Stress relieving helps to eliminate residual stresses that could lead to warping. 4. Support during machining: When machining stainless steel sheets, it is important to provide proper support to prevent warping. This can be achieved by using clamps or fixtures to securely hold the sheets in place. 5. Minimize heat exposure: Excessive heat can cause stainless steel sheets to warp. Therefore, it is important to avoid prolonged exposure to high temperatures during processes such as cutting, grinding, or forming. Using coolants or lubricants during these processes can help dissipate heat and minimize the risk of warping. 6. Choosing the right grade and thickness: Selecting the appropriate grade and thickness of stainless steel sheets for a specific application is essential. Thicker sheets generally have more resistance to warping, while certain grades of stainless steel may be more prone to distortion. Consulting with a materials expert or engineer can help in selecting the right stainless steel sheets for a particular project. By implementing these preventive measures, the risk of warping stainless steel sheets can be significantly reduced, ensuring their integrity and longevity.

- Q: Can stainless steel sheets be used for automotive body panels?

- Yes, stainless steel sheets can be used for automotive body panels. Stainless steel provides excellent corrosion resistance, durability, and aesthetic appeal, making it a suitable material for automotive applications.

- Q: Are stainless steel sheets resistant to UV radiation?

- Yes, stainless steel sheets are generally resistant to UV radiation. Stainless steel is primarily composed of iron, chromium, and other alloying elements, which provide excellent resistance to various forms of corrosion, including UV radiation. The chromium content in stainless steel forms a protective oxide layer on the surface, which acts as a barrier against UV rays and prevents the metal from oxidizing or deteriorating. However, it is important to note that prolonged exposure to intense UV radiation can still cause some discoloration or fading of the stainless steel surface over time. To maintain the aesthetics and integrity of stainless steel sheets in outdoor applications, it is recommended to periodically clean and protect the surface with appropriate treatments to ensure long-lasting performance.

- Q: What are the different types of surface finishes available for stainless steel sheets?

- Stainless steel sheets offer a range of surface finishes, each with its own distinct qualities and uses. 1. The most commonly used finish for stainless steel sheets is No. 1 Finish. It is achieved through hot rolling and annealing, resulting in a rough, dull appearance with visible grain lines. No. 1 finish is ideal for applications where a rough surface texture is desired, such as in industrial or structural uses. 2. No. 2B Finish is obtained by cold rolling the stainless steel sheet after a No. 1 finish, followed by annealing and descaling. It has a smooth, reflective surface with a slight matte appearance. No. 2B finish is frequently chosen for applications that require a clean, aesthetically pleasing look, such as kitchen appliances, architectural accents, and decorative items. 3. Known as a brushed finish, No. 3 Finish is achieved by mechanically polishing the stainless steel sheet with abrasive materials. It creates a satin-like appearance with a unidirectional pattern of fine lines. No. 3 finish is often used for decorative purposes, such as in furniture, signage, and elevator doors. 4. No. 4 Finish is similar to No. 3 finish, but it is achieved by mechanically polishing the stainless steel sheet with finer abrasives. This produces a smoother, more refined surface with a low gloss. No. 4 finish is commonly chosen for applications that require good corrosion resistance and easy maintenance, such as kitchen equipment, automotive trim, and architectural components. 5. The most reflective and luxurious surface finish for stainless steel sheets is No. 8 Mirror Finish. It involves progressively polishing the metal with finer abrasives until a highly reflective mirror-like surface is achieved. No. 8 mirror finish is often selected for decorative and high-end applications, such as architectural accents, jewelry, and luxury consumer goods. 6. Embossed finishes involve stamping or pressing a pattern onto the stainless steel sheet, creating a textured surface. These finishes can range from simple designs to intricate patterns, offering both aesthetic appeal and improved slip resistance. They are commonly used in applications that require both functionality and visual interest, such as in flooring, countertops, and wall cladding. In summary, the choice of surface finish for stainless steel sheets depends on the desired appearance, functionality, and performance requirements of the specific application.

- Q: Seeking stainless steel plate 304 material and 304j material what is the difference?

- 304 material and 304J1 contain nickel different, 304J1 contain 6 nickel, 304 contain 8 nickel

- Q: What are the different types of perforated patterns available for stainless steel sheets?

- There are several different types of perforated patterns available for stainless steel sheets, each designed to serve specific purposes and meet different aesthetic preferences. Some of the commonly used patterns include: 1. Round Hole Pattern: This is the most basic and widely used perforated pattern. It consists of evenly spaced round holes across the sheet, allowing for excellent airflow and drainage. It is commonly used in industrial applications such as filtration systems or as decorative panels. 2. Square Hole Pattern: Similar to the round hole pattern, the square hole pattern offers a more geometric and uniform appearance. It is often preferred for architectural and decorative purposes, as it provides a modern and sleek look. 3. Slotted Hole Pattern: Slotted holes are elongated and rectangular in shape, providing more flexibility in terms of airflow and visibility. They are often used in applications that require better drainage or where a higher open area is needed, such as in grills or air ventilation systems. 4. Hexagonal Hole Pattern: Hexagonal holes offer a unique and visually appealing pattern. They provide excellent strength and structural integrity, making them suitable for applications that require durability, such as safety barriers or machine guards. 5. Decorative Hole Pattern: Apart from the standard perforated patterns, there are also various decorative hole patterns available for stainless steel sheets. These patterns usually feature intricate designs or shapes, adding an artistic touch to architectural and interior design applications. It is important to consider the specific requirements of your project, such as airflow, visibility, drainage, or aesthetic appeal, when selecting the appropriate perforated pattern for stainless steel sheets. Consulting with a supplier or expert in the field can help you make an informed decision based on your needs.

- Q: Can stainless steel sheets be used for lighting fixtures?

- Yes, stainless steel sheets can be used for lighting fixtures. Stainless steel is a durable and corrosion-resistant material that is commonly used in various applications, including lighting fixtures. Its sleek and modern appearance also makes it a popular choice for many contemporary lighting designs.

- Q: Can stainless steel sheets be used for escalator steps?

- Yes, stainless steel sheets can be used for escalator steps. Stainless steel is a popular choice for escalator steps because it is durable, corrosion-resistant, and easy to clean. It also provides a sleek and modern appearance.

- Q: Are stainless steel sheets good for heat exchanger tubes?

- Stainless steel sheets are widely employed as heat exchanger tubes owing to their remarkable heat transfer capabilities and resistance to corrosion. The thermal conductivity of stainless steel is notably high, enabling efficient heat transfer between fluids. Moreover, its exceptional resistance to corrosion is vital for heat exchangers that frequently encounter corrosive liquids or gases. The longevity and reliability of stainless steel sheets guarantee the durability of heat exchanger tubes, making them a favored option in diverse industries like chemical processing, power generation, and HVAC systems.

- Q: Are stainless steel sheets suitable for aerospace applications?

- Yes, stainless steel sheets are suitable for aerospace applications. Stainless steel is a versatile and durable material that offers excellent strength-to-weight ratio, corrosion resistance, and high-temperature resistance, making it ideal for use in the aerospace industry. It is commonly used in the construction of aircraft structures, engine components, and fuel systems due to its ability to withstand extreme conditions and maintain structural integrity. Stainless steel sheets are also easy to form, weld, and fabricate, allowing for customization and precise engineering in aerospace applications. Additionally, stainless steel's resistance to fatigue and erosion makes it a reliable choice for aerospace components that are subject to constant stress and harsh environments. Overall, stainless steel sheets provide the necessary characteristics to meet the demanding requirements of the aerospace industry, making them a suitable choice for various applications.

Send your message to us

Stainless Steel Coils Hot Rolled NO.1 304 304L 316 316L Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords