2mm Cold Rolled Steel Sheet Iron Steel China Suppliers

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

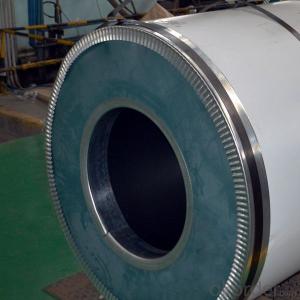

2mm Cold Rolled Steel Sheet Iron Steel China Suppliers

Quick Information

Standard: AISI, ASTM, BS, DIN, GB, JIS

Grade: DC01,SPCC,ST12

Thickness: 0.13~4.00mm

Model Number: DC01,SPCC,ST12

Type: Steel Coil

Technique: Cold Rolled

Surface Treatment: Oiled, Oiled

Application: Normal Formed Steel for Refrigerator Casing, Oil Drum, Steel Furniture, Refrigerator Casing, Oil Drum, Steel Furniture

Width: 600~1250mm

Length: Any Length Based on Coil Weight or by Required

Product Name: 2mm Cold Rolled Steel Sheet Iron Steel China Suppliers

Key Word: Cold Rolled Steel Sheet

Surface: Bright, Matt

Coil Inner Diameter: 508/610mm

Coil Weight: 3--10MT

Steel Grade: DC01,SPCC,ST12

MOQ: 25MT

Supply Ability: 550,000 MT per year

Specification

Commodity | 2mm Cold Rolled Steel Sheet Iron Steel China Suppliers | |||

Standard | AISI, ASTM, BS, DIN, GB, JIS,etc. | |||

Nominal Thickness | 0.13~4.00mm | |||

Nominal Width | 600~1250mm | |||

Length | Any length based on coil weight or by required | |||

Coil Inner Diameter | 508/610mm | |||

Surface | Bright, Matt | |||

Grade | DC01,SPCC,ST12 | |||

Delivery lead time | 15~30 Days after Receiving T/T Prepayment or LC Date | |||

Price term | FOB,CIF,CFR,EX Works,FCA | |||

Port of Loading | China Port | |||

Payment | L/C at Sight | |||

T/T 30% in Advance,70% Balance against B/L copy | ||||

Supply ability | 550,000 metric tons per year | |||

MOQ | 25 metric tons | |||

Packing | Mill's standard export sea-worthy packing | |||

Application | Normal Formed Steel for Refrigerator Casing, Oil Drum, Steel Furniture etc | |||

Packing and Package

Packing: Mill's standard export sea-worthy packing

MOQ: 25 MT( in one 20ft FCL)

Delivery time: 15-30 days after prepayment or L/C date

Remark: The third party inspection is accepted

Supply Ability

Product category | CR | GI/GL | PPGI/PPGL | Corrugated Steel Sheet | CRNGO |

Production lines | 4 | 4 | 3 | 2 | 1 |

Production capacity(MT/year) | 550000 | 700000 | 450000 | 28000 | 200000 |

Picture

- Q: I bought stainless steel appliances a year ago. I have two kids who like to put their hands all over the fridge and they always leave dirty marks all over it. I bought stainless steel cleaner but it doesn't do a good enough job. Anyone know any other cleaning remedies?

- Use stainless steel cleaner which you can get at hardware stores, Home Depot, and Lowes.

- Q: How are steel coils welded together?

- Different methods can be employed to weld steel coils together, depending on the specific requirements and the type of steel being used. Electric resistance welding (ERW) is a common method where an electric current is utilized to generate heat in the coils, melting their edges. Pressure is then applied to join them together. ERW is a cost-effective and speedy technique for welding steel coils. Thinner steel coils are often welded using high-frequency induction welding (HFIW). This involves the use of an induction coil to produce an alternating magnetic field, inducing an electric current in the coils. The resistance of the coils to this current generates heat, causing the edges to melt and form a weld. For thicker and heavier steel coils, submerged arc welding (SAW) is commonly employed. This technique utilizes a granular flux and a continuous electrode that is fed into the weld area. The flux melts, creating a protective shield for the weld pool, while the electrode melts to form the weld. SAW is a robust and efficient method for welding steel coils. In addition to these methods, laser welding and gas metal arc welding (GMAW) can also be utilized for welding steel coils. Laser welding offers high precision and speed, while GMAW, also known as MIG welding, utilizes an electric arc between a consumable wire electrode and the steel coils to create a weld. Irrespective of the welding method employed, successful welding of steel coils hinges on proper edge preparation, maintenance of appropriate heat and pressure levels, and the use of correct welding techniques.

- Q: Are steel coils used in the aerospace industry?

- Yes, steel coils are used in the aerospace industry for various applications such as manufacturing aircraft components, structural parts, and engine components.

- Q: How are steel coils priced and traded in the market?

- Steel coils are priced and traded in the market based on several factors. The primary factor is the current demand and supply dynamics of the steel industry. When the demand for steel coils is high, the prices tend to increase, and vice versa. Another important factor in pricing steel coils is the cost of raw materials, such as iron ore and coal, which are essential for steel production. Fluctuations in the prices of these materials can directly impact the pricing of steel coils. Additionally, the quality and specifications of the steel coils also play a significant role in determining their price. Higher-quality coils with specific characteristics, such as strength, corrosion resistance, or surface finish, may command a premium price in the market. The trading of steel coils is primarily done through various platforms, including physical exchanges, futures contracts, and over-the-counter (OTC) markets. Physical exchanges allow buyers and sellers to trade steel coils by exchanging physical deliveries. Futures contracts, on the other hand, enable traders to buy or sell steel coils at a predetermined price and future date, providing a way to hedge against price fluctuations. The OTC market is another avenue for trading steel coils, where buyers and sellers negotiate and agree on prices directly without going through a formal exchange. This provides flexibility and customization in trading, allowing for specific requirements to be met. Overall, the pricing and trading of steel coils in the market are influenced by demand and supply dynamics, raw material costs, quality specifications, and trading platforms. It is a complex process that requires careful consideration of various factors to determine fair prices and facilitate efficient trading.

- Q: Can steel coils be coated with epoxy?

- Yes, steel coils can be coated with epoxy. Epoxy coatings provide protection against corrosion and enhance the durability and lifespan of the steel coils.

- Q: How are steel coils used in the manufacturing of industrial conveyors?

- Steel coils are used in the manufacturing of industrial conveyors as the primary material for the conveyor belts. They are formed into circular shapes and then cut into strips to create the belt. Steel coils provide strength, durability, and flexibility to the conveyor belts, allowing them to withstand heavy loads and operate smoothly.

- Q: I have a set of Stainless steel pots and pans. Everything is sticks to them. What must I do so things don't stick?

- I only cook acidic foods in stainless steel or tomato sauces, Marinara sauces. Or sauces with wine in it. Because stainless steel is good with those kind of foods. Maybe you should use a little more fat, butter or Olive oil. And don't get the pan too hot, ( I don't care what other ppl say). Sometimes I heat up the pan and put a pat of butter in the pan to judge how hot it is. Once the butter starts sizzling or sputtering, the pan has reached the right temperature. Don't let the butter burn, the pan is too hot if the butter scorches. You can put a tablespoon (or less) olive oil in the skillet first and then a pat of butter; let them blend together. The oil will help keep the butter from burning.

- Q: Can steel coils be coated with abrasion-resistant materials?

- Yes, steel coils can be coated with abrasion-resistant materials. These materials are applied to the surface of the steel coils to provide added protection against wear and tear caused by friction and other abrasive forces. This coating helps prolong the lifespan of the steel coils and maintain their performance in various applications.

- Q: Im looking at some knives and am wandering if they use good steel one is this case knife and its 54 dollars Do they use good steel or not Iv never had a good experience with Case but am wandering if they use good steel now? if you all have any other recommendations let me hear them I got my Selection from here so any others wont hurt. so basic break down does case use good steel know?

- Vintage Case Knives

- Q: 1943 steel pennies

- if you collect coins, you need to learn that they must never be cleaned. cleaning, while it might make them look pretty, ruins their value as a collectable. ask your coin dealer.

Send your message to us

2mm Cold Rolled Steel Sheet Iron Steel China Suppliers

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords