Stainless Steel Coils 200 Series From China With High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

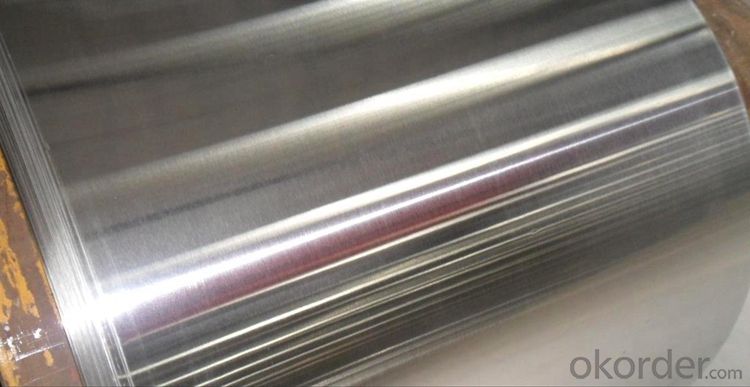

Products Description for Stainless Steel Coils/Sheets:

Item | cold rolled 201 stainless steel coil |

Technical | Hot rolled and cold rolled |

Standard | ASTM A240,GB/T3280-2007,JIS4304-2005,ASTM A167,EN10088-2-2005,GB/T3280-2007,EN10095-99,JIS4312,etc |

Material | 201,202,304,304L,309S,310S,316,316L,316Ti,430 |

Surface | NO.1,2b,4K,8k,HL,mirror finish |

Thickness | 0.3-100mm |

Width | 500-2000mm |

Price term | FOB,CFR,CIF |

Application | Stainless steel coil applies to construction field, ships building industry, petroleum, chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. Stainless steel coil can be made according to the customer’s requirements. |

Contact | If you have any question, please feel free to contact me. |

Specifications for Stainless Steel Coils/Sheets:

Grade | C ≤ | Si ≤ | Mn ≤ | P ≤ | S ≤ | Ni ≤ | Cr ≤ |

201 | 0.12 | 0.75 | 7.00 | 0.045 | 0.045 | 1.00-1.28 | 13.70-15.70 |

202 | 0.15 | 1.00 | 2.25 | 0.045 | 0.045 | 4.07-4.17 | 14.00-16.00 |

304 | 0.08 | 0.75 | 2.00 | 0.045 | 0.03 | 8.00-11.00 | 18.00-20.00 |

304L | 0.035 | 0.75 | 2.00 | 0.045 | 0.03 | 8.00-13.00 | 18.00-20.00 |

309 | 0.15 | 0.75 | 2.00 | 0.045 | 0.03 | 12.00-15.00 | 22.00-24.00 |

310S | 0.08 | 1.50 | 2.00 | 0.045 | 0.03 | 19.00-22.00 | 24.00-26.00 |

316 | 0.08 | 1.00 | 2.00 | 0.045 | 0.03 | 10.00-14.00 | 16.00-18.00 |

316L | 0.035 | 0.75 | 2.00 | 0.045 | 0.03 | 10.00-15.00 | 16.00-18.00 |

321 | 0.04-0.10 | 0.75 | 2.00 | 0.045 | 0.03 | 9.00-13.00 | 17.00-20.00 |

405 | 0.08 | 0.75 | 1.00 | 0.045 | 0.03 | 0.06 | 11.5-13.5 |

409 | 0.089 | 1.00 | 1.00 | 0.045 | 0.05 | 0.06 | 10.50-11.75 |

410 | 0.15 | 0.75 | 1.00 | 0.045 | 0.03 | 0.06 | 11.5-13.5 |

420 | 0.16-0.25 | 1.00 | 1.00 | 0.040 | 0.03 | 0.06 | 12.00-14.00 |

430 | 0.12 | 0.75 | 1.00 | 0.045 | 0.03 | 0.06 | 16.00-18.00 |

Packaging & Delivery for Stainless Steel Coils/Sheets:

Packaging Detail | Standard export packing or following customer's demand |

Delivery Time | Within 30-40 days after deposit or according to the order quantity |

Detail picture for Stainless Steel Coils/Sheets

FAQ for Stainless Steel Coils/Sheets:

Q:How to order?

A: Please send us your purchase order by email or fax .or you can ask us to send you a proforma invoice for your order .We need to know the following information for your order.

1) Shipping information-company name, street address, phone number, fax number, destination sea port

2) Product information – Quantity, Specification (steel type, thickness, width, surface finish)

3) Delivery time required

4) Forwarder's contact details if there's any in China

FAQ for Stainless Steel Coils/Sheets:

Q: How can I get the samples?

A: If you need some samples to test ,please pay for the transportation freight of samples and our samples are free for you.

Q: How can I get your price list?

A: Please send us your email or fax and order information – Quantity, Specification (steel type, thickness, width, surface finish), then I can send you the price list.

- Q: What are the different types of stainless steel sheet perforations available?

- There exists a variety of stainless steel sheet perforations, each possessing its own distinctive characteristics and applications. Among the most prevalent types are: 1. Round hole perforations: These perforations, characterized by evenly spaced round holes, are the simplest and most commonly employed. They ensure sufficient airflow and visibility. 2. Square hole perforations: Similar to their round counterparts, square hole perforations offer a distinct aesthetic and may be utilized for ventilation or decorative purposes. 3. Slotted perforations: Elongated in shape, slotted holes provide a larger open area compared to round or square holes. Consequently, they are often employed for drainage or filtering applications. 4. Hexagonal hole perforations: Hexagonal holes, featuring an exclusive pattern, are frequently used for architectural or decorative applications. They are also effective in facilitating airflow and visibility. 5. Decorative perforations: These perforations exhibit diverse shapes and designs, such as floral, geometric, or abstract patterns. Primarily employed for decorative purposes, they are commonly found in building facades or interior design. 6. Micro-perforations: These minute holes, typically less than 1mm in diameter, are utilized in applications necessitating high precision and fine filtration, like speaker grills or air diffusers. When selecting the appropriate perforation type, it is crucial to consider the specific requirements of your application. Factors such as open area, strength, visibility, and aesthetics must all be carefully evaluated to guarantee the most suitable choice for your specific needs.

- Q: What is the fire rating of stainless steel sheets?

- The fire rating of stainless steel sheets is typically determined based on their thickness and the specific grade of stainless steel employed. Stainless steel possesses inherent fire-resistant characteristics, as it does not readily melt, ignite, or aid in the propagation of flames. Nonetheless, the fire rating might differ depending on the intended use and the regulatory standards adhered to. Generally speaking, stainless steel sheets are regarded as possessing commendable fire resistance. However, if a precise fire rating is necessary, it is advisable to seek guidance from the manufacturer or a fire protection engineer for more precise information.

- Q: Can stainless steel sheets be used for kitchen sinks?

- Yes, stainless steel sheets can be used for kitchen sinks. Stainless steel is a popular and durable material choice for kitchen sinks due to its resistance to corrosion, heat, and staining. It is also easy to clean and maintain, making it a suitable option for a kitchen sink.

- Q: Are stainless steel sheets resistant to erosion corrosion?

- Yes, stainless steel sheets are highly resistant to erosion corrosion. This is primarily due to the presence of chromium in the alloy, which forms a protective layer of chromium oxide on the surface of the steel. This layer acts as a barrier, preventing oxygen and moisture from reaching the underlying metal and thus protecting it from corrosion. Furthermore, stainless steel sheets are also resistant to erosion corrosion caused by various chemicals and acids. The alloy composition of stainless steel, which typically includes elements such as nickel and molybdenum, enhances its resistance to corrosion in harsh environments. This makes stainless steel sheets suitable for a wide range of applications, including in industries such as chemical processing, oil and gas, and marine. However, it is important to note that the resistance of stainless steel sheets to erosion corrosion can vary depending on the specific grade or alloy used. Different grades may have different levels of corrosion resistance, so it is essential to choose the appropriate grade based on the specific environmental conditions and requirements of the application. Regular maintenance and proper handling can also help prolong the lifespan and maintain the corrosion resistance of stainless steel sheets.

- Q: Can stainless steel sheets be recycled after use?

- Stainless steel sheets are indeed recyclable once they have served their purpose. This material is highly recyclable and possesses qualities that make it perfectly suited for recycling. The process of recycling stainless steel entails melting the sheets to extract the raw materials, which can subsequently be utilized in manufacturing new stainless steel products. By recycling stainless steel, not only are we conserving natural resources, but we are also reducing energy consumption and the emission of greenhouse gases that are typically associated with the production of fresh stainless steel. Therefore, it is strongly advised to recycle stainless steel sheets in order to foster sustainability and promote the principles of a circular economy.

- Q: Are stainless steel sheets resistant to heat and high temperatures?

- Yes, stainless steel sheets are highly resistant to heat and high temperatures. Stainless steel is known for its excellent heat resistance properties, allowing it to maintain its strength and structural integrity even at extreme temperatures. This makes stainless steel sheets suitable for a wide range of applications where heat and high temperatures are involved, such as in industrial furnaces, boilers, heat exchangers, and automotive exhaust systems. Stainless steel can withstand temperatures up to 1200 degrees Celsius (2192 degrees Fahrenheit) without losing its structural properties, making it a popular choice in industries that require materials capable of withstanding intense heat. Additionally, stainless steel also exhibits good oxidation resistance, preventing the formation of rust or scale when exposed to high temperatures over prolonged periods. Overall, stainless steel sheets are an excellent choice for applications requiring resistance to heat and high temperatures.

- Q: What are the different types of edge finishes available for stainless steel sheets?

- There are several different types of edge finishes available for stainless steel sheets. These finishes are applied to the edges of the sheets to provide a clean and polished appearance, as well as to protect against sharp edges and potential corrosion. 1. Mill Finish: This is the standard edge finish for stainless steel sheets. It is the raw, untreated edge that is produced during the manufacturing process. While it may have a slightly rough or uneven appearance, it is still functional and commonly used for industrial applications. 2. Deburred Edges: In order to remove any sharp or jagged edges, the stainless steel sheet can be deburred. This is done by grinding or sanding down the edges to create a smoother and safer finish. Deburred edges are commonly used in applications where safety is a concern, such as in food processing or medical equipment. 3. Rounded Edges: Rounded edges are created by using a rounding tool to smooth out the sharp corners of the stainless steel sheet. This type of edge finish not only enhances the aesthetics of the sheet, but also reduces the risk of injury from sharp edges. Rounded edges are often preferred for architectural or decorative applications. 4. Beveled Edges: Beveled edges are achieved by cutting or grinding the edge of the stainless steel sheet at a specific angle, typically 45 degrees. This creates a chamfered edge that adds a sleek and modern look to the sheet. Beveled edges are commonly used in applications where aesthetics and design are important, such as in furniture or interior design. 5. Polished Edges: Polished edges involve buffing or polishing the edge of the stainless steel sheet to create a smooth and mirror-like finish. This type of edge finish adds a touch of elegance and sophistication to the sheet, making it suitable for high-end architectural or decorative applications. In summary, the different types of edge finishes available for stainless steel sheets include mill finish, deburred edges, rounded edges, beveled edges, and polished edges. Each finish offers its own unique benefits and is chosen based on the specific requirements of the application.

- Q: Can stainless steel sheets be used for water tanks or storage containers?

- Certainly, water tanks or storage containers can be made using stainless steel sheets. This material is widely chosen for these purposes because of its remarkable resistance to corrosion and durability. Its ability to resist rust and corrosion makes it perfect for storing water or other liquids. Moreover, stainless steel is hygienic and effortless to clean, which is vital for preserving the purity of stored water or food items. Furthermore, stainless steel sheets can be easily shaped and sized to meet the specific needs of the water tank or storage container. All in all, stainless steel sheets are a dependable and enduring choice for water tanks or storage containers.

- Q: What is stainless steel plate wire?

- But in the stainless steel industry said decimillimeter, such as stainless steel plate with the thickness of 1mm, the tolerance of 0.91 plus or minus 1 wire, a tolerance of plus or minus 0.01mm 0.91mm. That is to say here is actually in mathematics centimillimeter decimillimeter.1 wire =0.01 mm

- Q: What is the tensile modulus of stainless steel sheets?

- The tensile modulus of stainless steel sheets typically ranges from 180 to 200 GPa (Gigapascals).

Send your message to us

Stainless Steel Coils 200 Series From China With High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords