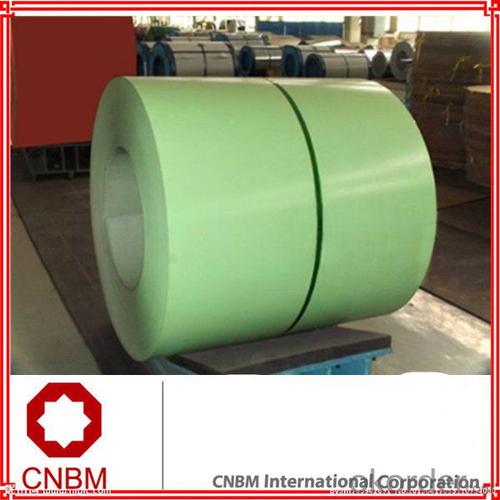

Color coated galvanized steel coil from china supplier

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 31234 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Color coated galvanized steel coil from china supplier

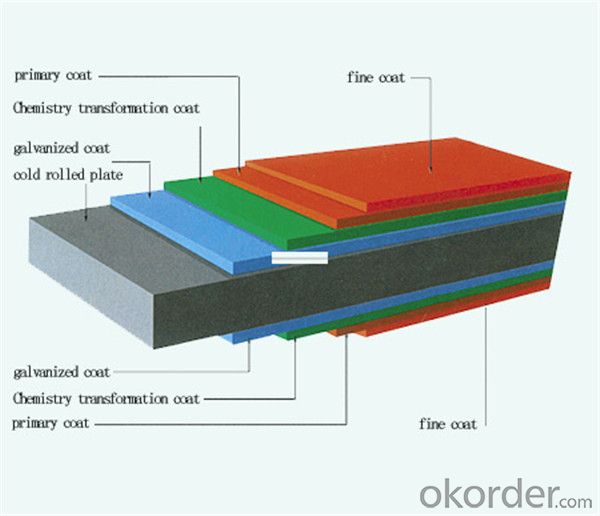

Prepainted steel sheet /coil is coated with organic layer, which provides higher anti-corrosion property and a

longer lifespan than that of galvanized steel sheets.

The base metals for prepainted steel sheet consist of cold-rolled, HDG electro-galvanized and hot-dip Alu-zinc

coated. The finish coats of prepainted steel sheets can be classified into groups as follows: polyester, silicon

modified polyesters, polyvinylidene fluoride, high-durability polyester, etc

The production process has evolved from one-coating-and-one-baking to double-coating-and-sigle-baking,double-coating

-and-double-baking and even three-coating-and-three-baking

Standard and Grade :

Pre-paint galvanized steel coil | ||||

ASTM A755M-03 | EN10169:2006 | JISG 3312-2012 | ||

Commercial quality | CS | DX51D+Z | CGCC | |

Structure steel | SS GRADE 230 | S220GD+Z | CGC340 | |

SS GRADE 255 | S250GD+Z | CGC400 | ||

SS GRADE 275 | S280GD+Z | CGC440 | ||

SS GRADE 340 | S320GD+Z | CGC490 | ||

SS GRADE550 | S350GD+Z | CGC570 | ||

S550GD+Z | ||||

Application :

Outdoor | Roof, roof structure, surface sheet of balcony, frame of window, door of garage, rolled shutter door, booth, Persian blinds, cabana, etc |

Indoor | Door, isolater, frame of door, light steel structure of house, home electronic appliances, ect. |

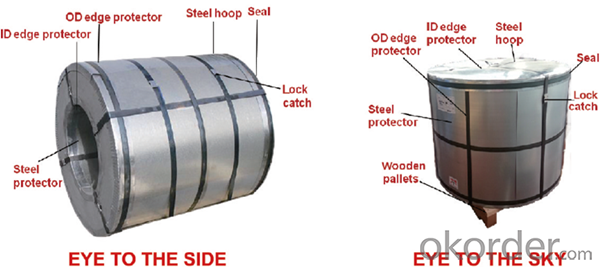

Packing:

Packaging Detail | The packing of coil consists of anti-damp paper ,PVC film ,hardboard paper , steel box , strapped with steel strips, fitted with locks and edge protectors and guarantees the optimal condition of the delivered goods. Each coil can be additionally fitted with wooden/steel skids(eye of the side) or wooden pallets(eye of the sky) |

Delivery Time | within 30 days of receipt of LC original or prepayment |

FAQ:

1. What’s the application of this product?

Roof, roof structure, surface sheet of balcony, frame of window, etc.

2. What’s the brand of the paint?

We use the best brand of all of the word—AKZO.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link

from raw material to final product we have strict quality test;We resolutely put an end to

unqualified products flowing into the market. At the same time, we will provide necessary

follow-up service assurance.

4. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange

the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but

the shipment will depend on the vessel situation

- Q: If rail ties were melted, would they be like any other type of steel?

- Hoghead has it top, it particularly is quite gentle steel, every time they war harder steel it does no longer arise to the stress and breaks greater with no difficulty. Rail, ordinary because it sort of feels can get corrugated and tough comparable as a dirt street and needs to be reground each so often to reshape the coolest part of the rail. Rust isn't a difficulty on a song in use so stainless could be a pointless cost. additionally, in extreme placed on places, terrific welding crews are available in in upload new cloth to the main worn areas, as in switches and then regrind it to the right profile, gentle steel accepts this plenty greater efficient than a harder steel could.

- Q: How are galvanized steel coils different from regular steel coils?

- Galvanized steel coils differ from regular steel coils in terms of their protective coating. Galvanized steel coils are coated with a layer of zinc, which provides a protective barrier against corrosion and rust. This process, known as galvanization, involves dipping the steel coils into a bath of molten zinc or applying zinc onto the surface through various methods. Regular steel coils, on the other hand, do not have this protective coating, making them more susceptible to corrosion and rust. The zinc layer on galvanized steel coils not only acts as a physical barrier but also provides sacrificial protection, meaning that if the coating gets scratched or damaged, the zinc sacrifices itself to protect the underlying steel from corrosion. This makes galvanized steel coils highly durable and suitable for applications that require resistance to harsh environmental conditions, such as outdoor construction projects, automotive manufacturing, and the production of household appliances.

- Q: I have heartgold and I don't have a steel type Pokemon to beat lapras. HELP

- actually, steel isn't very good against water, so i would go with a water or electric type pokemon.

- Q: How are steel coils used in the production of pipelines?

- Steel coils are an essential component in the production of pipelines. These coils, made from high-quality steel, are used to manufacture the pipes themselves. The process begins by unrolling the steel coil and cutting it into the desired size and length. The cut pieces are then shaped into cylindrical tubes using a process called pipe forming. Once the pipes are formed, they undergo various additional processes to enhance their strength and durability. This may include welding, heat treatment, and coating to protect against corrosion. Steel coils are also used to create the necessary fittings and connectors that are essential for connecting and joining the pipes together. The use of steel coils in pipeline production offers several advantages. Firstly, steel is a strong and durable material, making it ideal for handling the high pressure and stress that pipelines endure. Additionally, steel is resistant to corrosion, which is crucial for pipelines that transport various substances such as oil, gas, or water. Furthermore, steel coils allow for efficient production processes. The uniformity of the coils ensures consistent pipe dimensions, resulting in easy assembly and installation. The versatility of steel also allows for customization, enabling manufacturers to produce pipes of various sizes and specifications to meet specific project requirements. In conclusion, steel coils play a vital role in the production of pipelines. They are used to create the pipes themselves, as well as the necessary fittings and connectors. The use of steel ensures strength, durability, and corrosion resistance, making it the preferred material for pipelines. Moreover, steel coils enable efficient production processes and offer versatility in terms of customization.

- Q: What are the common handling defects in steel coils?

- Some common handling defects in steel coils include coil damage, coil slippage, coil edge damage, coil distortion, and coil contamination. These defects can occur during transportation, loading and unloading, handling, and storage of the coils.

- Q: What is the weight of a typical steel coil?

- The weight of a typical steel coil can vary significantly depending on its size, thickness, and type of steel used. However, a typical steel coil can range anywhere from a few hundred kilograms to several tonnes in weight.

- Q: Will a 1 inch thick A36 steel target withstand a 7.62x54r round?

- It sure will. It will also be a major pain in the back side to move it to where you can safely shoot at it.

- Q: What are the applications of steel coils in the aerospace industry?

- The aerospace industry relies heavily on steel coils for various purposes. One important application is in the manufacturing of aircraft structures. Steel coils are commonly used to fabricate wing spars, fuselage frames, and landing gear, as they possess high strength and durability necessary to withstand heavy loads and extreme conditions. Another significant use of steel coils in the aerospace industry is in the production of engine components, specifically turbine blades. These blades experience high temperatures and rotational forces, making it crucial to utilize steel coils due to their excellent heat resistance and mechanical properties. This ensures the reliability and performance of aircraft engines. Steel coils also find utilization in the production of fasteners and connectors necessary for securely joining different parts of an aircraft. Bolts, nuts, and rivets made from steel coils are essential for maintaining the structural integrity and safety of the aircraft. These fasteners need to possess high tensile strength and corrosion resistance. Furthermore, steel coils are employed in the production of fuel tanks and hydraulic systems. The weldability and formability of steel allow for the efficient fabrication of these complex structures. Steel coils can be shaped into various sizes and configurations, providing flexibility in designing fuel tanks and hydraulic components that meet specific requirements. In conclusion, steel coils are indispensable in the aerospace industry. Their use in aircraft structures, engine components, fasteners, and fuel tanks highlights their versatility and reliability. The exceptional strength, durability, heat resistance, and formability of steel make it the preferred material for various aerospace applications, ultimately ensuring the safety and performance of aircraft.

- Q: What are the challenges in welding steel coils?

- In order to guarantee successful and high-quality welds, it is necessary to address various challenges encountered when welding steel coils. One primary challenge involves achieving appropriate joint preparation. Steel coils often exhibit different surface conditions, such as rust, scale, or oil, which must be cleaned or eliminated before welding. This demands extensive cleaning and preparation to establish a clean and reliable welding surface. Another challenge lies in controlling the heat input. Due to the thin nature of steel coils, excessive heat can result in distortion, warping, or even burn-through. Welding operators must exercise careful control over the heat input to prevent such issues and uphold the integrity of the coils. Additionally, the presence of residual stresses poses a significant difficulty. Steel coils typically endure various stresses during the manufacturing, transportation, and handling processes, which can lead to distortion or cracking during welding. To mitigate these stresses and prevent potential defects, sufficient preheating and post-weld heat treatment may be necessary. Ensuring proper weld penetration is also of utmost importance. Steel coils often possess varying thicknesses, making it challenging to achieve consistent and adequate weld penetration throughout the joint. Welding operators must select appropriate welding parameters and techniques to guarantee complete fusion and a robust bond. Lastly, the size and weight of steel coils can create logistical challenges during welding. Specialized equipment and precise positioning are required to handle large and heavy coils, ensuring safe and efficient welding. Additionally, the length of the coils may necessitate multiple passes or continuous welding, demanding skilled operators and meticulous coordination. In conclusion, welding steel coils necessitates careful attention to joint preparation, heat control, stress relief, weld penetration, and logistical considerations. Overcoming these challenges guarantees the production of welded steel coils that are of high quality and durability.

- Q: I know that it is used for katanas and swords but what is it and is it good i am pretty sure that it is the process of the steel but can I have a little more information.

- It's a special type of steel that was made in Syria. It is used to make swords or knives. It's mostly used in Middle East and South Asia.

Send your message to us

Color coated galvanized steel coil from china supplier

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 31234 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords