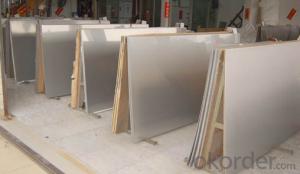

Stainless Steel 304 sheet with competitive pricing and top quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t

- Supply Capability:

- 1000000 m.t/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Stainless steel 304 sheet

Company advantage of stainless steel:

-Top Equipments, Leading In The Industry.

- Professional Team, Leading Innovation.

- Huge Supply Capacity Advantage, Timely and Effective Delivery.

- Modern Logistic, Fact and Convenient.

- Precise Manufacturing, Exquisite Products.

- Serve People, Create Value.

- Dimensional Network, Powerful Expansion.

Product Information of stainless steel sheet:

- Q: Are stainless steel pipes suitable for hygienic applications?

- Yes, stainless steel pipes are suitable for hygienic applications. Stainless steel is widely used in industries such as food processing, pharmaceuticals, and dairy, where maintaining cleanliness and preventing contamination is crucial. Stainless steel pipes have several properties that make them ideal for hygienic applications. Firstly, stainless steel is highly resistant to corrosion, which is important for maintaining hygiene and preventing the growth of bacteria or other pathogens. It does not rust or corrode easily, even when exposed to various chemicals and cleaning agents used in hygienic environments. This resistance to corrosion ensures the integrity of the pipes and prevents any contamination from occurring. Secondly, stainless steel has a smooth, non-porous surface that is easy to clean and sanitize. The smoothness of the surface prevents the accumulation of dirt, bacteria, or other particles, making it easier to maintain a hygienic environment. Stainless steel pipes can be easily cleaned using various cleaning methods, including steam, high-pressure water, or chemical cleaning agents. Furthermore, stainless steel is a durable and long-lasting material. It can withstand high temperatures and pressures, making it suitable for a wide range of hygienic applications. Stainless steel pipes can be used for transporting fluids, gases, or other materials without compromising their hygienic properties. In addition, stainless steel is a non-reactive material, meaning it does not react with the substances it comes into contact with. This property is important for preventing any contamination or alteration of the substances being transported through the pipes. Overall, stainless steel pipes are highly suitable for hygienic applications due to their corrosion resistance, smooth surface, durability, and non-reactive properties. They provide a reliable and hygienic solution for industries where cleanliness and prevention of contamination are of utmost importance.

- Q: What are the weld sleeves for stainless steel pipes?

- The process is the same as you set for the pipe welding material quota, stainless steel drop can, on the line in the budget when a show

- Q: Can stainless steel pipes be cut to length?

- Certainly! Stainless steel pipes have the capability of being cut into desired lengths. Stainless steel, being a versatile substance, lends itself easily to cutting through various means like sawing, cutting wheels, or even plasma cutting. The choice of a specific method relies on factors such as the thickness and diameter of the pipe, along with the level of precision sought in the cut. Ensuring a clean and precise cut necessitates the use of suitable tools and techniques.

- Q: What are the different standards and specifications for stainless steel pipes?

- There are several different standards and specifications for stainless steel pipes, which vary based on their intended use and the region in which they are being used. Some of the most common standards and specifications for stainless steel pipes include: 1. ASTM (American Society for Testing and Materials): ASTM A312/A312M is a standard specification for seamless, welded, and heavily cold worked austenitic stainless steel pipes. This specification covers various grades of stainless steel pipes for high-temperature and general corrosive service. 2. ASME (American Society of Mechanical Engineers): ASME B36.19M is a standard specification for stainless steel pipes that covers the dimensions, wall thickness, and tolerances for both welded and seamless pipes. ASME B36.10M is another standard that specifies the dimensions and tolerances for seamless and welded stainless steel pipes. 3. EN (European Norms): EN 10216-5 is an European standard that specifies the technical delivery conditions for stainless steel seamless pipes for pressure purposes. EN 10217-7 is another European standard that covers welded stainless steel tubes for pressure purposes. 4. JIS (Japanese Industrial Standards): JIS G3459 is a standard specification for stainless steel pipes that are used for high-temperature service. JIS G3468 specifies the stainless steel pipes for general service. 5. DIN (Deutsches Institut für Normung): DIN EN 10216-5 is a German standard that specifies the technical delivery conditions for stainless steel seamless pipes for pressure purposes. DIN EN 10217-7 is another German standard that covers welded stainless steel tubes for pressure purposes. These are just a few examples of the numerous standards and specifications available for stainless steel pipes. It is important to consult the appropriate standard and specification based on the specific requirements and application of the stainless steel pipes to ensure proper performance and compliance with industry standards.

- Q: What's the difference between cold drawn steel tube and hot rolled steel tube?

- Hot rolling is relative to cold rolling, cold rolling is performed under recrystallization temperature, while hot rolling is rolling above recrystallization temperature.Seamless steel pipe, hot-rolled and cold-rolled (DIAL) seamless steel pipe two categories.Hot rolled steel tubes are divided into ordinary steel tubes, low and medium pressure boiler tubes, high pressure boiler tubes, alloy steel pipes, stainless steel pipes, oil cracking pipes, geological steel pipes and other steel pipes, etc..

- Q: Can stainless steel pipes be used in high-pressure applications?

- Yes, stainless steel pipes can be used in high-pressure applications. Stainless steel is known for its strength, durability, and ability to withstand extreme pressure conditions. It is often used in industries such as oil and gas, chemical processing, and power generation, where high-pressure environments are common. Stainless steel pipes offer excellent resistance to corrosion, making them suitable for long-term use in high-pressure applications.

- Q: Can stainless steel pipes be used for power plants?

- Indeed, power plants can utilize stainless steel pipes. The selection of stainless steel for power plant purposes is frequently made as a result of its exceptional resistance to corrosion and its ability to endure elevated temperatures and pressures. Given that power plants commonly operate in aggressive surroundings, they necessitate materials that can endure these conditions without deterioration. With its outstanding resistance to corrosion from chemicals, gases, and water, stainless steel pipes are perfectly suited for power plant applications. Furthermore, these pipes necessitate minimal maintenance, thereby reducing downtime and overall expenses.

- Q: What is the external insulation used for stainless steel pipes?

- The external insulation used for stainless steel pipes is typically made of a variety of materials such as mineral wool, fiberglass, or foam. These insulating materials are applied to the exterior surface of the stainless steel pipes to provide thermal insulation and protect against heat loss or gain. The insulation helps to maintain the temperature of the fluid or substance flowing through the pipes, preventing condensation and reducing energy loss. Additionally, the external insulation can also provide protection against corrosion and mechanical damage, ensuring the longevity and efficiency of the stainless steel pipes.

- Q: How can galvanized steel pipe be connected with stainless steel pipe?

- Welding flanges respectively, with flange connection, but galvanized pipe according to specifications, dynamic welding after two times galvanized,

- Q: 310 stainless steel resistance to high temperature?

- Features: suitable for making all kinds of furnace components, with a maximum temperature of 1200 degrees, continuous use temperature of 1150 degrees CelsiusUses: furnace materials, materials for automotive cleaning equipment

Send your message to us

Stainless Steel 304 sheet with competitive pricing and top quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t

- Supply Capability:

- 1000000 m.t/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords