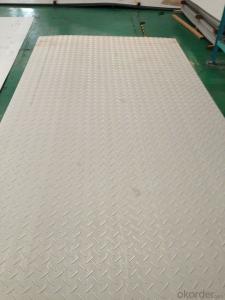

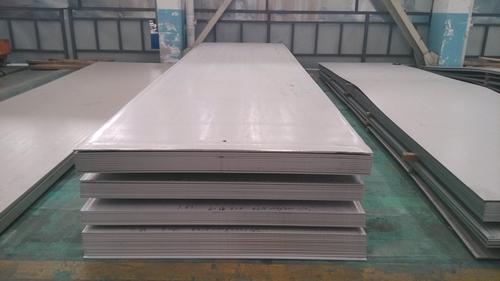

Stainless Steel 304 sheet with reasonable pricing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t

- Supply Capability:

- 1000000 m.t/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Stainless steel 304 sheet

Company advantage of stainless steel:

-Top Equipments, Leading In The Industry.

- Professional Team, Leading Innovation.

- Huge Supply Capacity Advantage, Timely and Effective Delivery.

- Modern Logistic, Fact and Convenient.

- Precise Manufacturing, Exquisite Products.

- Serve People, Create Value.

- Dimensional Network, Powerful Expansion.

Product Information of stainless steel sheet:

- Q: Stainless steel pipe specification 25*2 what does it mean?

- Stainless steel pipe specification 25*2, indicating stainless steel pipe, the outer diameter of 25mm, wall thickness of 2mm.

- Q: Are stainless steel pipes suitable for high-pressure applications?

- Indeed, high-pressure applications find stainless steel pipes to be fitting. Recognized for their remarkable durability and ability to resist corrosion, stainless steel emerges as a material ideally suited for managing fluids or gases under high pressure. It maintains its shape and integrity even when subjected to high pressures, guaranteeing system safety and reliability by averting deformities or leaks. Furthermore, the smooth internal surface of stainless steel pipes reduces flow resistance and impedes the accumulation of debris or contaminants, thereby heightening their suitability for high-pressure applications.

- Q: What is the welding of stainless steel?

- If batch welding, it is recommended to use laser welding, welding heat affected area is small, weld appearance, speed, more suitable for thin plate,

- Q: How do you calculate the pipe volume for a specific application?

- To calculate the pipe volume for a specific application, you need to multiply the cross-sectional area of the pipe by its length. The cross-sectional area can be determined by using the formula for the area of a circle (πr^2), where r is the radius of the pipe. Once you have the cross-sectional area, multiply it by the length of the pipe, and you will have the volume.

- Q: What is the maximum pressure rating for stainless steel pipe fittings?

- There are several factors that contribute to the maximum pressure rating of stainless steel pipe fittings, including the material grade, size, and temperature. In general, stainless steel pipe fittings have the ability to handle high-pressure applications due to their strength and resistance to corrosion. The pressure rating of these fittings can vary greatly, ranging from 150 psi to as high as 10,000 psi, depending on the specific fitting and its intended use. To determine the maximum pressure rating for a particular stainless steel pipe fitting, it is important to refer to the manufacturer's documentation or industry standards such as ASME B16.11 or ASME B16.9. Additionally, when working with high-pressure systems, other factors such as the sealing method, compatibility with the conveyed fluid, and any necessary safety precautions must be taken into consideration.

- Q: Can stainless steel pipes be used for transportation of hazardous materials?

- Indeed, hazardous materials can be transported using stainless steel pipes. The reason for this is that stainless steel is renowned for its resistance to corrosion, its strength, and its durability, all of which make it appropriate for handling various types of hazardous substances. In industries such as chemicals, petrochemicals, oil and gas, and pharmaceuticals, where the transportation of hazardous materials is a routine occurrence, stainless steel pipes are frequently employed. The corrosion resistance of stainless steel ensures that it can endure exposure to a wide range of chemicals without deteriorating. This is particularly crucial when transporting hazardous materials that have the potential to react with or corrode other materials. Moreover, stainless steel pipes possess high strength, enabling them to withstand the pressures and stresses associated with the transportation of hazardous materials. Furthermore, stainless steel pipes can maintain the integrity of the hazardous material being transported by preventing contamination from external sources. Stainless steel, being inert and having a smooth surface, is resistant to the formation of deposits that could potentially react with or contaminate the hazardous materials. However, it is worth noting that careful consideration should be given to the selection of the appropriate stainless steel grade and its compatibility with the specific hazardous material being transported. Different stainless steel alloys possess distinct characteristics, so it is crucial to choose the grade that can withstand the specific chemical properties of the hazardous material. Additionally, it is always important to adhere to regulations and standards governing the transportation of hazardous materials in order to ensure safety and compliance. These regulations may include specific requirements regarding the design, fabrication, and testing of the stainless steel pipes used for transportation. To conclude, stainless steel pipes can effectively be employed for the transportation of hazardous materials due to their corrosion resistance, strength, and durability. However, it is vital to consider the specific requirements of the hazardous material and to adhere to relevant regulations to ensure the safe and efficient transportation of such materials.

- Q: Are stainless steel pipes resistant to sulfide stress corrosion cracking?

- Yes, stainless steel pipes are generally resistant to sulfide stress corrosion cracking due to their high chromium content which forms a passive protective layer on the surface, preventing corrosion.

- Q: What is the difference between the stainless steel pipe welded pipe and seamless pipe?

- Seamless tube is a strip of steel with a hollow cross section and no seams at all. The general is rolled into a cylindrical tube plate welding.

- Q: How do stainless steel pipes perform in extreme weather conditions?

- Stainless steel pipes perform exceptionally well in extreme weather conditions due to their high resistance to corrosion, heat, and cold. They can withstand extreme temperatures, heavy rainfall, snow, and intense sunlight without deteriorating or losing their structural integrity. This makes them a reliable choice for various applications in industries such as oil and gas, construction, and marine environments.

- Q: Can stainless steel pipes be insulated with polyethylene naphthalate?

- Yes, stainless steel pipes can be insulated with polyethylene naphthalate (PEN). Polyethylene naphthalate is a high-performance thermoplastic material that offers excellent insulation properties. It has low thermal conductivity, which makes it suitable for insulating pipes and preventing heat loss or gain. Additionally, PEN has good resistance to chemicals, moisture, and UV radiation, making it a durable choice for pipe insulation. However, it is important to ensure that the selected insulation material is compatible with the specific application and operating conditions to ensure optimal performance and longevity.

Send your message to us

Stainless Steel 304 sheet with reasonable pricing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t

- Supply Capability:

- 1000000 m.t/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords