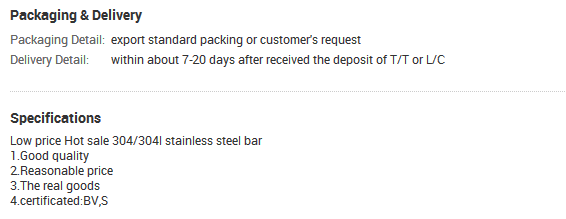

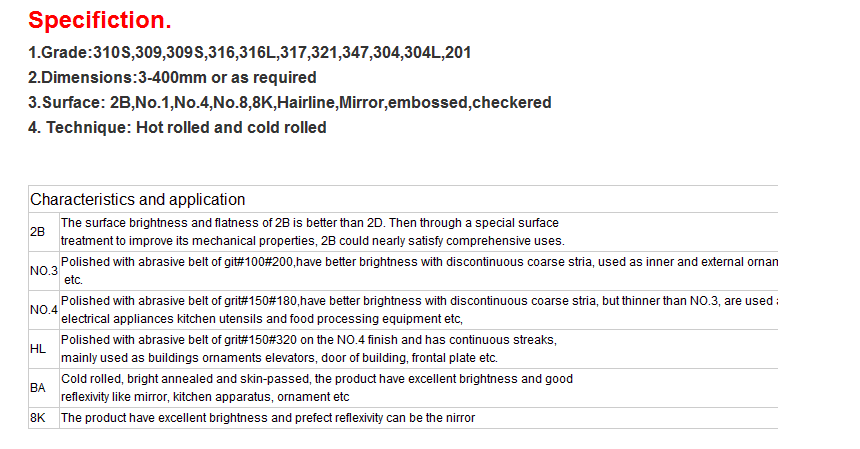

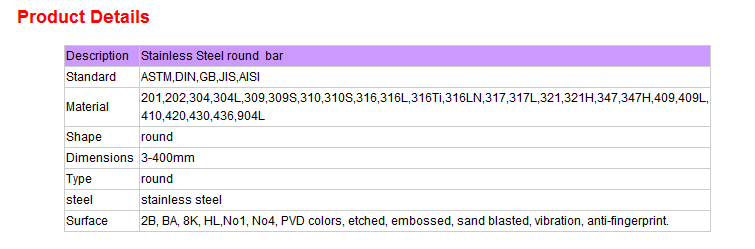

Low price Hot sale 304/304l stainless steel bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 1000 kg/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

- Q: Are stainless steel pipes suitable for high-temperature environments?

- Yes, stainless steel pipes are suitable for high-temperature environments. They have excellent heat resistance properties, ensuring their stability and structural integrity even at elevated temperatures. Additionally, stainless steel pipes exhibit good corrosion resistance, making them a reliable choice for various industrial applications involving high temperatures such as power plants, refineries, and chemical processing plants.

- Q: What are the common shapes of stainless steel pipes?

- Stainless steel pipes come in various shapes that are widely utilized across different industries. These shapes comprise of round pipes, square pipes, rectangular pipes, and oval pipes. Round pipes rank among the most prevalent shapes and find extensive use in diverse applications. They are primarily employed for fluid and gas transportation, as well as the conveyance of other materials. Furthermore, round pipes are well-suited for structural purposes like handrails, scaffolding, and support beams. Square pipes possess a square cross-section and are commonly employed in construction projects, architectural designs, and furniture manufacturing. They offer a sleek and contemporary appearance, often utilized for framing structures, manufacturing shelves, and creating decorative elements. Rectangular pipes possess a rectangular cross-section and are frequently utilized in the construction, engineering, and manufacturing industries. They are often employed in building frameworks, manufacturing gates, fences, and various structural components. Oval pipes possess an elliptical or oval shape and are used in applications where aesthetics play a significant role. They are a popular choice in architectural designs, the automotive industry, and decorative applications. In conclusion, the selection of stainless steel pipe shape depends on the specific requirements of the application and desired aesthetics. Each shape offers distinct advantages and is chosen based on factors such as strength, durability, ease of fabrication, and overall design requirements.

- Q: Can stainless steel pipes be used for oil and gas transportation?

- Indeed, the utilization of stainless steel pipes for the transportation of oil and gas is plausible. Due to its exceptional resistance to corrosion and durability, stainless steel has become a favored material choice within the oil and gas industry for pipe construction. These pipes possess the capability to endure harsh circumstances, including high pressure, extreme temperatures, and corrosive surroundings, rendering them appropriate for the conveyance of oil and gas. Furthermore, the purity of the transported fluids is maintained by stainless steel pipes, as they exhibit no reactivity or contamination towards the substances being conveyed. As a result, stainless steel pipes are an unquestionably dependable and efficient option for oil and gas transportation.

- Q: How do you calculate the deflection of stainless steel pipes under load?

- To calculate the deflection of stainless steel pipes under load, you can utilize the theory of beam bending. This involves analyzing the pipe as a beam and applying the principles of bending moment and deflection. First, you need to determine the moment of inertia (I) of the stainless steel pipe. This can be done by using the formula specific to the shape of the pipe, such as for a circular pipe: I = π * (D^4 - d^4) / 64, where D is the outer diameter and d is the inner diameter of the pipe. Next, you need to calculate the bending moment (M) acting on the pipe. This is typically obtained from the applied load, which can be in the form of a force, pressure, or weight acting on the pipe. The bending moment can be determined by multiplying the load by the distance between the applied load and the point of interest on the pipe. Once you have the moment of inertia (I) and bending moment (M), you can calculate the maximum deflection (δ) using the formula: δ = (M * L^2) / (E * I), where L is the span length of the pipe and E is the modulus of elasticity for stainless steel. It's important to note that these calculations assume the stainless steel pipe is perfectly elastic and has a homogeneous material composition. Real-world factors like material properties, pipe geometry, and boundary conditions may affect the accuracy of the calculated deflection. Therefore, it is recommended to consult relevant engineering codes, standards, or professional resources to ensure accurate and safe calculations.

- Q: Advantages and disadvantages of PPR lined stainless steel pipe and PPR aluminium plastic pipe

- 1 、 excellent resistance to temperature and pressurePP-R tube and aluminum layer organic combination, with higher strength and better temperature resistance, pressure resistance performance, more suitable for high temperature hot water field use2, small thermal expansion deformationThe thermal expansion coefficient is small (3 x 10-5m/m - C), similar to metal pipe, avoid the pipe deformation due to temperature changes, reduce the number of free arm compensation for pipe deformation, is ideal for heating and central air-conditioning system.3, light blocking oxygenThe intermediate aluminum layer is insulated from oxygen to avoid the oxidation and corrosion of the metal parts in the heating and central air conditioning system, thus effectively prolonging the service life of the system.

- Q: Can stainless steel pipes be used in nuclear power plants?

- Yes, stainless steel pipes can be used in nuclear power plants. Stainless steel is often used in the construction of nuclear power plants due to its excellent corrosion resistance, high strength, and ability to withstand high temperatures. It is particularly suitable for applications involving the transport of coolant, steam, and other fluids within the plant.

- Q: What is the difference between 321 and 316 stainless steel pipes?

- The main difference between 321 and 316 stainless steel pipes lies in their chemical composition and intended applications. 321 stainless steel pipes contain titanium, which stabilizes the material against chromium carbide formation. This makes it highly resistant to intergranular corrosion, even at elevated temperatures. As a result, 321 stainless steel pipes are commonly used in applications where high temperatures are involved, such as in the aerospace and power generation industries. On the other hand, 316 stainless steel pipes do not contain titanium but have molybdenum in their composition. This addition enhances the material's corrosion resistance, particularly in environments with chloride ions, making it suitable for applications in marine and coastal environments. Additionally, 316 stainless steel pipes are often used in the food and beverage industry due to their excellent resistance to acids and chemicals. In summary, while both 321 and 316 stainless steel pipes offer excellent corrosion resistance, the presence of titanium in 321 stainless steel pipes provides enhanced resistance to intergranular corrosion at high temperatures, whereas the addition of molybdenum in 316 stainless steel pipes improves their resistance to chloride-based corrosion in marine and coastal environments.

- Q: Can stainless steel pipes be used for pulp and paper industry applications?

- Stainless steel pipes are indeed suitable for use in various applications within the pulp and paper industry. Due to their exceptional durability and resistance to corrosion, stainless steel pipes can be utilized in a range of industrial settings, including those found in the pulp and paper sector. This industry involves the transportation of corrosive substances and fluids, such as acids, bleaching agents, and solvents, which have the potential to deteriorate and erode standard pipes over time. Conversely, stainless steel pipes possess corrosion resistance properties, enabling them to endure the harsh chemicals and elevated temperatures typically encountered in pulp and paper plants. Furthermore, these pipes are also known for their hygienic nature and ease of cleaning, rendering them highly suitable for applications where cleanliness is of utmost importance, such as in the production of food-grade paper. In summary, stainless steel pipes represent a dependable and long-lasting choice for the pulp and paper industry.

- Q: How do stainless steel pipes compare to PEX pipes?

- Different plumbing systems require different characteristics and applications, making stainless steel pipes and PEX pipes suitable options. Stainless steel pipes are renowned for their durability and strength, making them ideal for water supply systems, especially in areas with aggressive water conditions. Their resistance to corrosion and ability to withstand high pressure and temperature make them suitable for both residential and commercial use. Moreover, stainless steel pipes are fire-resistant and have a long lifespan, requiring minimal maintenance and offering cost-effectiveness in the long term. On the other hand, PEX pipes, composed of cross-linked polyethylene, provide flexibility and easy installation. These pipes are highly resistant to freezing and bursting, making them a great choice for cold-climate regions. Their capacity to expand and contract reduces the risk of leaks or bursts caused by temperature changes. Additionally, PEX pipes are corrosion-resistant, eliminating the need for costly and time-consuming maintenance. They also dampen noise and vibration, providing a quieter alternative to metal pipes. When making a decision between stainless steel pipes and PEX pipes, it is crucial to consider specific plumbing requirements, budget, and local building codes. While stainless steel pipes excel in durability and strength, PEX pipes offer flexibility and ease of installation. Ultimately, the choice depends on the unique needs of the plumbing system and the preferences of the homeowner or plumbing professional.

- Q: Stainless steel pipe pickling ratio

- Usage: used for contaminant removal of various types of stainless steel parts, sheet metal surface and its equipment rust, oxide skin, after welding of yellow blue black spot welding, a silver white metal surface cleaning, and surface passivation, corrosion resistance of stainless steel.

Send your message to us

Low price Hot sale 304/304l stainless steel bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 1000 kg/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords