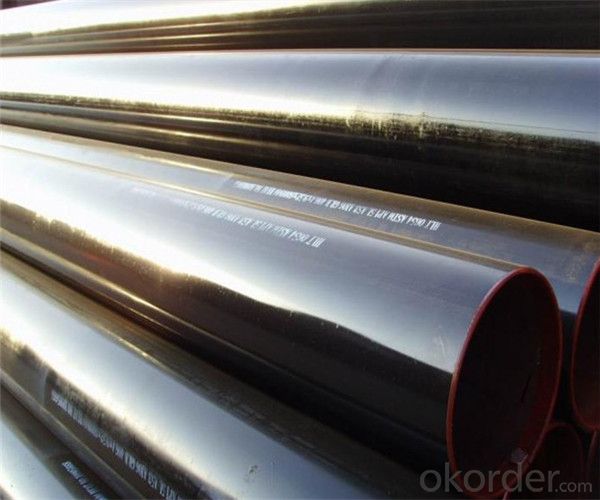

Seamless Steel Pipe with Best Price and High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 2000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PRODUCT DETAILS

1.Structure of Seamless Steel Pipe Description:

A large amount of Seamless Steel Pipes is offered to the clients at cost effective rates. These pipes are extremely durable, resistant to corrosion and have high tensile strength. Our pipes are used in nuclear plants, power plants, refineries and construction industry across the country. Furthermore, we are capable of providing these seamless pipes to the clients in bulk quantity.

2.Main Features of the Steel Pipe:

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

•Reasonable price

3.Packaging & Delivery:

| Packaging Details: | Seaworthy packages, bundles wrapped with strong steel strip |

| Delivery Detail: | 15-30 days after received 30% TT |

4.Seamless Steel Pipe Specification:

| Standard: | GB, DIN, ASTM,ASME, ASTM A106-2006, ASTM A53-2007 |

| Grade: | 10#,20#, 45#, 16Mn |

Thickness: | 8 - 33 mm |

| Section Shape: | Round |

| Outer Diameter: | 133 - 219 mm |

| Place of Origin: | Shandong, China (Mainland) |

| Secondary Or Not: | Non-secondary |

| Application: | Hydraulic Pipe |

| Technique: | Cold Drawn |

| Certification: | API |

| Surface Treatment: | factory state or painted black |

| Special Pipe: | API Pipe |

| Alloy Or Not: | Non-alloy |

| Length: | 5-12M |

| Outer Diameter: | 21.3-610mm |

5.FAQ of Seamless steel pipe:

①How is the quality of your products?

Our products are manufactured strictly according to national and internaional standard, and we take a test

on every pipe before delivered out. If you want see our quality certifications and all kinds of testing report, please just ask us for it.

Guaranteed: If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

②How about price?

Yes, we are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”,if you like bargain and factory price is not low enough as you think, just don’t waste your time.Please trust the quotation we would give you, it is professional one.

③Why should you chose us?

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer’s trust.

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

Any question, pls feel free to contact us !

- Q: What is the impact toughness of steel pipes?

- The ability of steel pipes to withstand sudden or high-velocity impacts without fracturing or breaking is referred to as their impact toughness. This property measures the material's resistance to cracking when subjected to dynamic loading conditions. The impact toughness of steel pipes is highly significant as it determines their capacity to endure accidental impacts or external forces during transportation, installation, and operation. To evaluate the impact toughness of steel pipes, standardized tests such as the Charpy V-notch test or the Izod test are commonly utilized. These tests involve striking a notched sample of the steel pipe with a pendulum or a falling weight and measuring the amount of energy absorbed by the material until it fractures. The impact toughness is then calculated based on this energy absorption. A high impact toughness is desirable in steel pipes as it signifies a greater ability to absorb energy and resist fracture, making them more resilient to sudden impacts or loading conditions. This characteristic is particularly crucial in applications where steel pipes are exposed to high-stress environments, such as in oil and gas pipelines, automotive components, or structural applications. Several factors can influence the impact toughness of steel pipes, including their chemical composition, heat treatment, and microstructure. For instance, alloying elements like manganese, chromium, and nickel can enhance the impact toughness by promoting the formation of fine-grained microstructures and preventing crack propagation. Similarly, appropriate heat treatment processes like quenching and tempering can optimize the material's microstructure and mechanical properties, thereby improving its impact toughness. In conclusion, the impact toughness of steel pipes is a vital property that determines their ability to withstand sudden or high-velocity impacts. It is evaluated through standardized tests and can be influenced by factors such as chemical composition, heat treatment, and microstructure. A high impact toughness is desirable in steel pipes to ensure their structural integrity and resistance to fracture when subjected to dynamic loading conditions.

- Q: Can steel pipes be used for structural supports?

- Yes, steel pipes can be used for structural supports. Steel pipes are strong, durable, and have high load-bearing capacity, making them suitable for providing structural support in various applications such as buildings, bridges, and infrastructure projects.

- Q: What is the difference between steel pipes and plastic pipes?

- Steel pipes are made from a strong and durable metal, while plastic pipes are made from synthetic materials like PVC or polyethylene. Steel pipes are typically used for high-pressure applications and in areas where strength and durability are key factors. On the other hand, plastic pipes are more lightweight, corrosion-resistant, and easier to install. They are commonly used for low-pressure applications and in areas where chemical resistance is important.

- Q: Can steel pipes be used for underground cable protection?

- Yes, steel pipes can be used for underground cable protection. Steel pipes provide excellent durability, strength, and resistance to external factors such as impact, corrosion, and fire. They can effectively shield and protect underground cables, ensuring their safety and longevity.

- Q: How are steel pipes protected against abrasive wear?

- Steel pipes are protected against abrasive wear through various methods such as using protective coatings, lining the pipes with wear-resistant materials, or employing internal or external liners. These measures ensure that the steel pipes can withstand the erosive effects of abrasive materials and extend their lifespan.

- Q: Can steel pipes be used for conveying slurry?

- Indeed, steel pipes possess the capability to serve as a conveyance for slurry. In numerous industries, steel pipes find extensive usage in the transportation of diverse fluid varieties, including slurry. Slurry, a liquid containing suspended solid particles, is effectively accommodated by steel pipes due to their robustness, endurance, and corrosion resistance. The adeptness of steel pipes in managing such mixtures is further enhanced by their ability to handle high pressures and temperatures, rendering them suitable for conveying slurry in arduous applications like mining, dredging, and wastewater treatment. Moreover, the ease of welding steel pipes enables the construction of lengthy pipelines that efficiently facilitate the transport of slurry across considerable distances. Nonetheless, it is vital to consider the specific attributes of the slurry being conveyed, such as particle size, density, and abrasiveness, to ensure the selection and design of pipes that guarantee optimal performance and longevity.

- Q: What are the future trends in steel pipe manufacturing?

- Some future trends in steel pipe manufacturing include the use of advanced technologies such as robotic automation and artificial intelligence for increased efficiency and precision. There is also a growing focus on sustainability, with the development of eco-friendly manufacturing processes and the use of recycled materials. Additionally, there is a shift towards producing pipes with higher strength and lighter weight, as well as an increasing demand for customized products to meet specific industry requirements.

- Q: How are steel pipes used in the manufacturing of furniture?

- Steel pipes are often used in the manufacturing of furniture as structural components. They are commonly employed for creating sturdy frames for chairs, tables, and other items. The pipes provide strength and durability, allowing furniture to withstand heavy loads and daily use. Additionally, steel pipes are often used for creating unique designs and modern aesthetics in furniture pieces.

- Q: What are the different methods of heat treatment for steel pipes?

- Some of the different methods of heat treatment for steel pipes include annealing, normalizing, quenching, and tempering. Annealing involves heating the steel pipe to a specific temperature and then slowly cooling it to make it softer and more ductile. Normalizing is a similar process but involves air cooling instead of slow cooling. Quenching is a rapid cooling process that results in a hardened and brittle steel pipe. Tempering follows quenching and involves reheating the steel pipe to a lower temperature to reduce the brittleness and improve its toughness.

- Q: How are steel pipes connected in pipeline construction?

- Steel pipes are connected in pipeline construction through various methods, including welding, threading, and flanges. Welding involves joining the pipes by melting the edges and fusing them together, creating a strong and continuous connection. Threading involves screwing the pipes together using threaded ends, ensuring a secure connection. Flanges are used to connect pipes with the help of bolts, providing a detachable yet sturdy connection. These methods ensure the integrity and safety of the pipeline system.

Send your message to us

Seamless Steel Pipe with Best Price and High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 2000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords