304 Stainless Steel Sheet with competitive price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

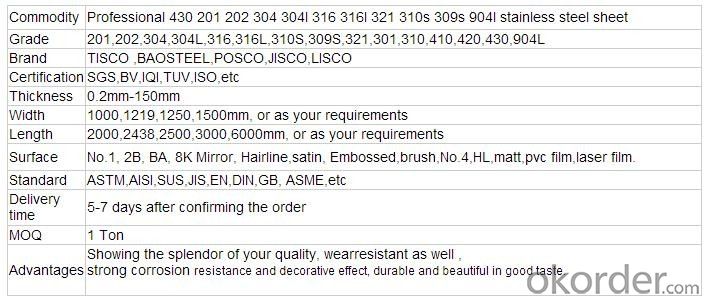

Specification

304 stainless steel sheet with competitive price

Product Photos

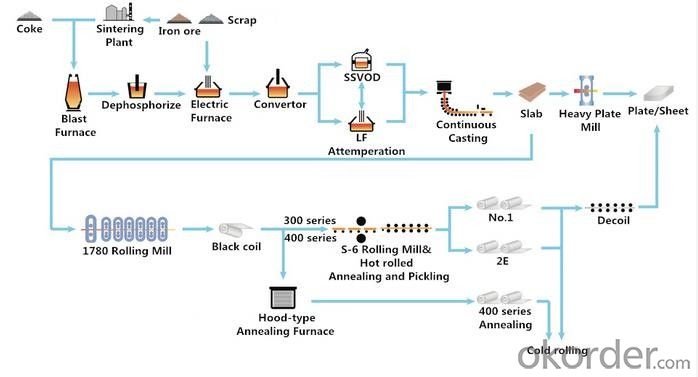

Production Flow

Production Flow about stainless steel sheet

Raw materials are sending to hot rolling units for rolling into different sizes

Hot rolled material is annealing in cold; rolled annealing furnace and pickling in acid.

All mill rolls are grinded on precision grinding machine with proper chamfering after first shiftoperation.

All sheets are pickled in different tanks and dried on brush roll machine before dispatched.

These sheets are again annealing and are sent to straighten machine for straightening.

Inspections are done at various stages. Keep proper control overall internal process via rolling,annealin and pickling by our experienced staff

Product Uses

Application--stainless steel sheet/plate

Stainless steels of various kinds are used in thousands of applications. The following gives a flavour of the full range:

1.Domestic – cutlery, sinks, saucepans, washing machine drums, microwave oven liners, razor blades

2.Transport – exhaust systems, car trim/grilles, road tankers, ship containers, ships chemical tankers, refuse vehicles

3.Oil and Gas – platform accommodation, cable trays, subsea pipelines.

4.Medical – Surgical instruments, surgical implants, MRI scanners.

5.Food and Drink – Catering equipment, brewing, distilling, food processing.

6.Water – Water and sewage treatment, water tubing, hot water tanks.

7.General – springs, fasteners (bolts, nuts and washers), wire.

8.Chemical/Pharmaceutical – pressure vessels, process piping.

9.Architectural/Civil Engineering – cladding, handrails, door and window fittings, street furniture, structural sections,reinforcement bar, lighting columns, lintels, masonry supports.

Related Products

Related Product:

Our Services

Services:

1.Sample:Free samples will be available for most of the products, but usually the freight ,charges need to paid by your side.

2.Inquiry:24 hours online to ensure your inquiry will be replied within 12 hours .

3.Delivery:Most products can be delivered within 7 days after order.

4.Small order also can be accepted.

Why Choose

1. We have professional export team.

2.We can provide Mill test certificate.

3.we cooprationwith more than 20 countries.

4.wu have good service&short delivery time.

5.we can provide free sample for your evalution.

6.All products are made of high-quality stainless steel sheet.

Certificate--ISO,BV,SGS,TUV,IQI or other third inspections.

Package--wooden pallets without fimugated,iron pallets,water proof papers,

interleaved paper,pvc film,20'GP or 40'GP container.

We warmly welcome clients from all over the world to cooperate with us and develop worldwide market together. Also we hope we can have chance to establish longterm business relationship with you on the basis of mutual benefits!

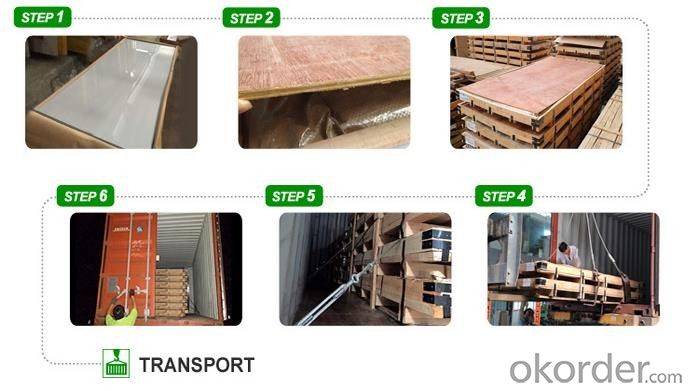

Packaging & Shipping

1 Sheets covered with wooden plate for protection in transportation.

2. All sheets will be loaded in strong wooden packages.

3. Every cartons loaded with good shoring and strengthening.

4. Take container loading pictures and seal the container.

5. Transportation speed is quick. And keep customer each step informed.

- Laser PVC: Poli-film, Novancel

- 70 /100 Micron Laser PVC

- Single/Double 70 Micron Black&white PVC.

- Q: Do stainless steel sheets have a warranty?

- Stainless steel sheets usually have a warranty, which can differ in duration and terms depending on the manufacturer and specific product. It is advisable to consult with the supplier or manufacturer to obtain precise information regarding the warranty coverage. Generally, defects in material or workmanship are covered by the warranty, and if any problems occur within the specified warranty period, the stainless steel sheet can be replaced or repaired. To maintain the warranty's validity, it is crucial to adhere to the care and maintenance instructions provided by the manufacturer.

- Q: What are the different types of etched finishes available for stainless steel sheets?

- Stainless steel sheets come in a range of etched finishes, each with its own unique and distinctive look. Let's explore some of the most common options: 1. Brushed Finish: A popular choice, this etched finish involves using a fine abrasive material to create a smooth and satin-like texture on the surface of the stainless steel sheet. 2. Bead Blasted Finish: For a matte and slightly rough appearance, small glass or ceramic beads are blasted onto the sheet at high pressure, resulting in a non-directional and uniform texture. 3. Mirror Finish: Also known as a No. 8 finish, this etched option gives the stainless steel sheet a flawless and shiny appearance. It involves a series of grinding, buffing, and polishing processes to create a highly reflective and mirror-like surface. 4. Satin Finish: Similar to the brushed finish but with a finer texture, this etched option uses a finer abrasive material during the brushing process, resulting in a soft and elegant appearance. 5. Patterned Finish: This etched finish allows for creative and customizable options, as it involves creating various patterns or designs on the sheet's surface. Techniques such as laser etching, chemical etching, or embossing can be used to achieve this effect. These different etched finishes offer a wide range of aesthetic choices for stainless steel sheets, making them suitable for various architectural, decorative, and industrial applications. The choice of finish depends on the desired appearance, functionality, and intended use of the sheet.

- Q: What are the different types of stainless steel sheet finishes for marine applications?

- Marine applications commonly employ various types of stainless steel sheet finishes to enhance durability, corrosion resistance, and aesthetic appeal. 1. No. 1 Finish: Generally utilized for structural applications, this rough and non-reflective finish is achieved through hot-rolling. It offers good corrosion resistance and is suitable for marine applications where aesthetics are not a primary concern. 2. No. 2B Finish: Achieved through cold-rolling, annealing, and pickling, this smooth and reflective finish boasts excellent corrosion resistance. It is widely used in marine applications that require a moderate level of aesthetics. 3. No. 4 Finish: This brushed finish features a dull and non-reflective surface. It is obtained by grinding with progressively finer abrasives until the desired appearance is achieved. No. 4 finish is commonly chosen for marine applications where aesthetics play a crucial role, as it provides a clean and uniform look. 4. No. 8 Mirror Finish: Highly reflective, this finish is achieved by polishing with progressively finer abrasives until a mirror-like surface is obtained. No. 8 mirror finish is commonly utilized in marine applications where a high level of aesthetics is desired, as it offers a visually appealing and reflective surface. 5. Satin Finish: This semi-reflective finish is achieved by brushing the stainless steel sheet with a fine abrasive material. Satin finish is often selected for marine applications that require a moderate level of aesthetics, as it provides a clean and visually appealing surface. Apart from these standard finishes, specialized finishes like textured or patterned finishes are available for marine applications to enhance slip resistance. The choice of finish depends on specific requirements, including corrosion resistance, aesthetics, and functionality in the marine application.

- Q: How are stainless steel sheets produced?

- Stainless steel sheets are produced through a series of manufacturing processes that involve various stages. The production of stainless steel sheets typically begins by melting raw materials such as iron ore, coal, and limestone in a blast furnace. This process is known as primary steelmaking and results in the production of molten iron. The molten iron is then transferred to a basic oxygen furnace (BOF) or electric arc furnace (EAF) where it is mixed with scrap steel and other alloys to adjust the desired chemical composition. The molten mixture undergoes a refining process to remove impurities and achieve the desired quality of stainless steel. Once the refining process is complete, the molten stainless steel is cast into slabs or billets. These large blocks of solidified metal are then heated and rolled into thin sheets through a process called hot rolling. Hot rolling involves passing the stainless steel through a series of rollers to reduce its thickness and shape it into the desired dimensions. After hot rolling, the stainless steel sheets undergo a process known as annealing. This process involves heating the sheets to a specific temperature and allowing them to cool slowly. Annealing helps to relieve internal stresses and improve the material's mechanical properties, such as strength and ductility. Following annealing, the stainless steel sheets may undergo further processing such as cold rolling, which involves passing the sheets through a series of rollers at room temperature to achieve the desired thickness and surface finish. Cold rolling also enhances the stainless steel's mechanical properties and improves its surface quality. Once the sheets have been cold rolled, they are typically coated with a protective film or passivation layer to prevent corrosion. This film acts as a barrier against environmental factors and helps maintain the longevity of the stainless steel sheets. Finally, the stainless steel sheets are cut into the desired sizes and shapes using various cutting techniques such as shearing or laser cutting. The sheets may undergo additional surface treatments, such as polishing or brushing, to achieve the desired aesthetic appearance. In summary, stainless steel sheets are produced by melting raw materials, refining the molten metal, casting it into slabs, hot rolling to reduce thickness, annealing to improve properties, cold rolling for further refinement, coating for corrosion resistance, and finally cutting and surface treatment to achieve the desired product.

- Q: Can stainless steel sheets be used for electromagnetic shielding?

- Yes, stainless steel sheets can be used for electromagnetic shielding. Due to its high electrical conductivity and magnetic permeability, stainless steel can effectively block electromagnetic radiation and protect sensitive electronic devices from interference.

- Q: What is the electrical resistivity of stainless steel sheets?

- The electrical resistivity of stainless steel sheets typically ranges from 70 to 80 micro-ohm centimeters (µΩ·cm).

- Q: Is there any magnetism in 304 stainless steel?

- Stainless steel friends are many, there are some differences in color, but not very good to distinguish. Can be judged according to the magnetic (magnet test): magnetic was 202 (ferritic stainless steel) magnetic or nonmagnetic small is 304 (stainless steel), are generally magnetic, but strength difference.

- Q: Can stainless steel sheets be used for food packaging or containers?

- Food packaging or containers can indeed utilize stainless steel sheets. The food industry widely employs stainless steel due to its numerous advantageous qualities. Its corrosion resistance guarantees that the food will not react with the container, ensuring safety for consumption. Moreover, stainless steel is highly durable, making it appropriate for long-term utilization in food packaging or containers. It is also effortless to clean and maintain, meeting the necessary hygiene standards. Furthermore, stainless steel containers or packaging can withstand extreme temperature changes, making them suitable for diverse food storage and transportation requirements. All in all, stainless steel sheets are a dependable and secure option for food packaging or containers.

- Q: Can stainless steel sheets be used in medical equipment?

- Yes, stainless steel sheets can be used in medical equipment. Stainless steel is a popular choice for medical devices and equipment due to its excellent properties such as corrosion resistance, durability, and ease of cleaning. It is commonly used in surgical instruments, implants, hospital equipment, and laboratory tools. Stainless steel sheets are often used in the fabrication of medical equipment due to their versatility and ability to be molded into various shapes and sizes. Additionally, stainless steel is highly biocompatible, meaning it does not react with bodily tissues and is safe for use in medical applications. Overall, stainless steel sheets are a reliable and widely accepted material for medical equipment due to their hygienic properties and long-lasting performance.

- Q: Can stainless steel sheets be used in the automotive industry?

- Indeed, the automotive industry does have the capability to employ stainless steel sheets. Owing to their remarkable strength, durability, and resistance to corrosion, stainless steel is frequently utilized in the assembly of automotive components. Exhaust systems, fuel tanks, bumpers, and trim are common examples of parts that are often crafted from this material. The utilization of stainless steel sheets grants manufacturers a great deal of flexibility in terms of design options, enabling them to fashion intricate forms and structures. Furthermore, due to its aesthetic appeal and ease of upkeep, stainless steel remains a favored choice in the automotive industry.

Send your message to us

304 Stainless Steel Sheet with competitive price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords