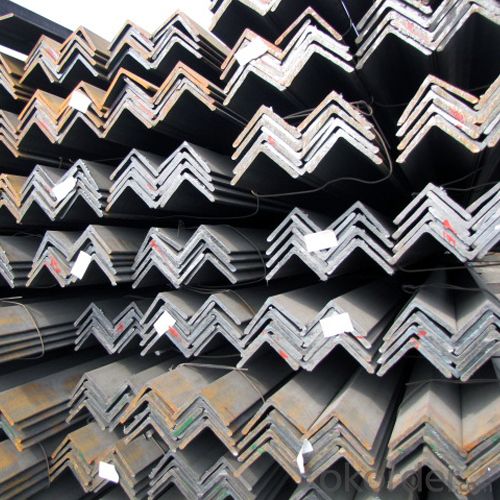

SS540 Material High Quality Angle Bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Angle Steel great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

According to the needs of different structures, Angle can compose to different force support component, and also can be the connections between components. It is widely used in various building structures and engineering structures such as roof beams, bridges, transmission towers, hoisting machinery and transport machinery, ships, industrial furnaces, reaction tower, container frame and warehouse etc.

Product Advantages:

OKorder's Angle Steelare durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

1. Invoicing on theoretical weight or actual weight as customer request

2. Length: 6m, 9m, 12m as following table

3. Sizes

Sizes: 25mm-250mm | ||

a*t | ||

25*2.5-4.0 | 70*6.0-9.0 | 130*9.0-15 |

30*2.5-6.6 | 75*6.0-9.0 | 140*10-14 |

36*3.0-5.0 | 80*5.0-10 | 150*10-20 |

38*2.3-6.0 | 90*7.0-10 | 160*10-16 |

40*3.0-5.0 | 100*6.0-12 | 175*12-15 |

45*4.0-6.0 | 110*8.0-10 | 180*12-18 |

50*4.0-6.0 | 120*6.0-15 | 200*14-25 |

60*4.0-8.0 | 125*8.0-14 | 250*25 |

Alloy No | Grade | Element (%) | |||||

C | Mn | S | P | Si | |||

|

|

|

|

|

|

| |

Q235 | B | 0.12—0.20 | 0.3—0.7 | ≤0.045 | ≤0.045 | ≤0.3 | |

|

|

|

|

|

|

| |

Alloy No | Grade | Yielding strength point( Mpa) | |||||

Thickness (mm) | |||||||

≤16 | >16--40 | >40--60 | >60--100 | ||||

≥ | |||||||

|

|

|

|

|

| ||

Q235 | B | 235 | 225 | 215 | 205 | ||

Alloy No | Grade | Tensile strength (Mpa) | Elongation after fracture (%) | ||||

Thickness (mm) | |||||||

| ≤16 | >16--40 | >40--60 | >60--100 | |||

≥ | |||||||

|

|

|

|

|

|

| |

Q235 | B | 375--500 | 26 | 25 | 24 | 23 | |

Quality Assurance of Alloy Steel for Bearing

We are the ISO 9001:2000 authentication enterprises and we can provide the enterprise's quality written guarantee for all the exported products.

Certificate of quality is issued in English, in addition the normal terms, production process, the mechanical property (yield strength, tensile strength, elongation and hardness. forged ratio, UT test result, Grain size, heat treatment methods and the sample of is shown on the certificate of quality.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2 Can stainless steel rust?

A2 Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Images:

- Q: How do steel angles differ from steel channels?

- Steel angles and steel channels are both structural steel shapes that are commonly used in construction and engineering applications. However, they differ in terms of their shape and structural properties. Firstly, steel angles have an L-shaped cross-section, with two legs that are perpendicular to each other. The legs can have equal or unequal lengths, depending on the specific application. This L-shaped design provides greater stability and strength, making steel angles ideal for applications that require load-bearing capabilities, such as supporting beams or columns. They are often used in the construction of frames, braces, and for reinforcing structures. On the other hand, steel channels have a U-shaped cross-section, with a flat bottom and two parallel legs that are connected by a vertical web. The legs of steel channels are usually tapered or have rounded edges. The U-shaped design allows steel channels to provide excellent resistance to bending and torsion, making them suitable for applications that require structural support and stability, such as the construction of framing systems, support beams, and building facades. Another key difference between steel angles and steel channels is their weight-bearing capacity. Steel angles, due to their L-shaped design and shorter legs, are generally more efficient in carrying vertical loads. Conversely, steel channels, with their wider and more extensive cross-section, are better suited to bear horizontal loads. In terms of installation, steel angles are typically bolted or welded to other steel members, providing a strong connection. Steel channels, on the other hand, can be connected by welding, bolting, or even by using clips or brackets, depending on the specific application and load requirements. In summary, steel angles and steel channels differ in terms of their cross-sectional shape, load-bearing capacity, and structural properties. Steel angles are L-shaped and are more suited for vertical load-bearing applications, while steel channels are U-shaped and are better suited for horizontal load-bearing applications. Both shapes have their respective advantages and are commonly used in various construction and engineering projects.

- Q: Are steel angles prone to rust or corrosion?

- Yes, steel angles are prone to rust or corrosion as they are typically made of carbon steel, which is susceptible to rusting when exposed to moisture and oxygen.

- Q: What are the common surface treatments used for steel angles?

- The common surface treatments used for steel angles are galvanizing, painting, and powder coating. Galvanizing is a process where a layer of zinc is applied to the surface of the steel angle to protect it from corrosion. This is achieved by immersing the steel angle in a bath of molten zinc or by applying a zinc coating using a specialized technique. Galvanized steel angles have a shiny, silver appearance and provide excellent corrosion resistance. Painting is another commonly used surface treatment for steel angles. The steel angle is typically primed and then coated with one or more layers of paint. This not only enhances the aesthetic appeal of the steel angle but also provides a protective barrier against rust and other environmental factors. Painting allows for a wide range of color options and finishes, making it a versatile choice for various applications. Powder coating is a dry finishing process where a fine powder, typically made of resin and pigment, is electrostatically applied to the steel angle's surface. The angle is then heated, causing the powder to melt and form a durable coating. Powder coating offers excellent resistance to scratches, chemicals, and UV rays. It is available in a wide array of colors and provides a smooth and even finish. The choice of surface treatment for steel angles depends on the specific application and the desired level of protection, aesthetics, and durability. Galvanizing is preferred in outdoor or corrosive environments, while painting and powder coating are commonly used for indoor applications or where a specific color or finish is desired.

- Q: How do you prevent and address corrosion in steel angles?

- Corrosion prevention and addressing in steel angles can be achieved through several effective measures. Here are some steps you can take: 1. Proper surface preparation: Thoroughly clean the steel angles before applying any protective measures. Remove any dirt, grease, or other contaminants using a suitable solvent or detergent. 2. Protective coatings: Applying a high-quality coating is crucial to prevent corrosion. Options include paints, primers, and specialized corrosion-resistant coatings designed for steel. Ensure the coating is compatible with the environmental conditions the steel angles will be exposed to. 3. Galvanization: Galvanizing steel angles can provide excellent corrosion resistance. This involves applying a layer of zinc to the surface, creating a barrier between the steel and the corrosive elements in the environment. 4. Regular inspection and maintenance: Periodically inspect the steel angles for signs of corrosion, such as rust or pitting. Address any corrosion issues immediately to prevent further damage. This may involve removing the damaged coating, treating the corroded area, and reapplying a protective coating. 5. Cathodic protection: For critical applications or aggressive environments, consider implementing cathodic protection. This technique involves connecting sacrificial anodes or installing impressed current systems to protect the steel angles from corrosion by creating an electrochemical reaction. 6. Environmental control: Limiting exposure to moisture, humidity, and corrosive chemicals can significantly reduce the risk of corrosion. Proper ventilation, dehumidification, and avoiding direct contact with corrosive substances are essential preventive measures. 7. Routine cleaning: Regularly clean the steel angles to remove any accumulated dirt, debris, or corrosive substances, as they can accelerate corrosion. Use gentle cleaning methods and avoid abrasive materials that can damage the protective coating. Remember, preventing and addressing corrosion in steel angles requires a proactive approach. By implementing these measures, you can extend the lifespan of the steel angles and maintain their structural integrity.

- Q: How do you calculate the radius of gyration for a steel angle?

- When calculating the radius of gyration for a steel angle, one must consider the dimensions and properties of the angle. This measure determines how the mass of an object is distributed around its axis of rotation, indicating the distance of the mass from the axis and its impact on rotational stability. The formula for determining the radius of gyration of a steel angle is as follows: k = √(I / A) In this formula: - k represents the radius of gyration - I denotes the moment of inertia regarding the angle's axis of rotation - A represents the cross-sectional area of the steel angle The moment of inertia (I) signifies an object's resistance to changes in rotational motion and depends on its shape and size. The cross-sectional area (A) of the steel angle refers to the total enclosed area within its shape. To calculate the moment of inertia, one can utilize the specific formula for the steel angle's shape. For instance, if the angle possesses equal flanges, the formula becomes: I = (b1 * h1³ + b2 * h2³) / 12 In this formula: - b1 and b2 denote the widths of the angle's flanges - h1 and h2 represent the thicknesses of the angle's flanges After determining the moment of inertia and the cross-sectional area, these values can be substituted into the radius of gyration formula to obtain the radius of gyration (k). It is essential to acknowledge that the radius of gyration is a theoretical value assuming the object possesses a perfect, homogeneous shape. In reality, factors like material imperfections, loading conditions, and connection details can impact the actual behavior and stability of a steel angle. Therefore, it is always advisable to consult engineering resources or professionals for accurate and specific calculations pertaining to structural design and analysis.

- Q: How do steel angles compare to other structural shapes like beams and channels?

- Steel angles, beams, and channels are all common structural shapes used in construction. While beams and channels are primarily used to carry loads in horizontal applications, steel angles are versatile and can be used in both horizontal and vertical applications. Unlike beams and channels, steel angles have two legs that form a 90-degree angle, providing greater stability and resistance to bending. Additionally, steel angles are often more cost-effective than beams and channels due to their simpler design. However, the choice between steel angles, beams, and channels ultimately depends on the specific requirements of the project and the loads they need to support.

- Q: Can steel angles be used for balcony railings?

- Yes, steel angles can be used for balcony railings. They are strong and durable, providing adequate support and safety for the balcony. Additionally, steel angles can be customized to fit the specific design and aesthetic requirements of the railing.

- Q: Can steel angles be used for conveyor systems?

- Yes, steel angles can be used for conveyor systems. Steel angles are commonly used in construction and industrial applications due to their strength, durability, and versatility. In conveyor systems, steel angles are often used to provide structural support and stability to the conveyor framework. They can be used to connect various components of the conveyor system, such as the conveyor belt, rollers, and motor, ensuring proper alignment and smooth operation. Additionally, steel angles can be easily fabricated and customized to meet specific design requirements, making them a suitable choice for conveyor systems of different sizes and configurations.

- Q: Are steel angles suitable for agricultural applications?

- Indeed, steel angles prove to be apt for agricultural applications. These multifunctional and long-lasting steel angles are well-suited for a range of agricultural needs. They can be employed to fashion robust frameworks for greenhouses, barns, and storage structures. By delivering exceptional structural reinforcement and enduring the weight of hefty burdens, steel angles are well-matched for erecting sturdy barriers, gates, and enclosures for livestock. Moreover, as steel angles are resistant to corrosion, they prove indispensable in agricultural settings that frequently encounter dampness and chemicals. The reliability of steel angles, owing to their adaptability and durability, renders them an optimal choice for agricultural purposes.

- Q: How are steel angles installed on concrete structures?

- Steel angles are commonly used in concrete structures to provide additional strength and support. The process of installing steel angles on concrete structures involves a few steps. First, the concrete surface needs to be prepared. This includes cleaning the surface thoroughly and removing any debris or loose material. The concrete should be in a sound condition, free from cracks or other structural issues. Next, the steel angles need to be positioned and marked on the concrete surface. This is typically done by using a measuring tape and a chalk line. The angles are usually placed at specific intervals and locations, based on the structural requirements. After marking the positions, the concrete surface needs to be drilled. This is done using a drill and a masonry bit that is appropriate for the size of the anchor bolts or fasteners that will be used. The holes should be drilled to the required depth, ensuring a secure and stable installation. Once the holes are drilled, anchor bolts or fasteners are inserted into the holes. These bolts or fasteners are specifically designed for securing steel angles to concrete surfaces. They are typically made of steel and have a threaded end that allows them to be tightened securely into the concrete. After inserting the anchor bolts or fasteners, the steel angles are positioned and aligned with the marked locations on the concrete surface. The angles are then secured to the concrete by tightening the nuts on the anchor bolts or fasteners. Finally, the installation is checked for accuracy and stability. The angles should be firmly attached to the concrete surface and should not move or shift when pressure is applied. Any adjustments or additional tightening may be necessary to ensure a secure and reliable installation. Overall, the process of installing steel angles on concrete structures involves careful preparation, drilling, anchoring, and securing. This ensures that the angles provide the necessary strength and support required for the specific application.

Send your message to us

SS540 Material High Quality Angle Bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords