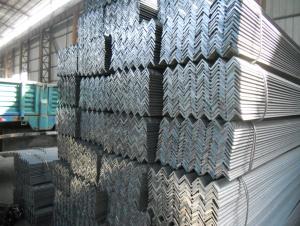

GB Standard High Quality Angle Bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Angle Steel great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

According to the needs of different structures, Angle can compose to different force support component, and also can be the connections between components. It is widely used in various building structures and engineering structures such as roof beams, bridges, transmission towers, hoisting machinery and transport machinery, ships, industrial furnaces, reaction tower, container frame and warehouse etc.

Product Advantages:

OKorder's Angle Steelare durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

1. Invoicing on theoretical weight or actual weight as customer request

2. Length: 6m, 9m, 12m as following table

3. Sizes

Sizes: 25mm-250mm | ||

a*t | ||

25*2.5-4.0 | 70*6.0-9.0 | 130*9.0-15 |

30*2.5-6.6 | 75*6.0-9.0 | 140*10-14 |

36*3.0-5.0 | 80*5.0-10 | 150*10-20 |

38*2.3-6.0 | 90*7.0-10 | 160*10-16 |

40*3.0-5.0 | 100*6.0-12 | 175*12-15 |

45*4.0-6.0 | 110*8.0-10 | 180*12-18 |

50*4.0-6.0 | 120*6.0-15 | 200*14-25 |

60*4.0-8.0 | 125*8.0-14 | 250*25 |

Alloy No | Grade | Element (%) | |||||

C | Mn | S | P | Si | |||

|

|

|

|

|

|

| |

Q235 | B | 0.12—0.20 | 0.3—0.7 | ≤0.045 | ≤0.045 | ≤0.3 | |

|

|

|

|

|

|

| |

Alloy No | Grade | Yielding strength point( Mpa) | |||||

Thickness (mm) | |||||||

≤16 | >16--40 | >40--60 | >60--100 | ||||

≥ | |||||||

|

|

|

|

|

| ||

Q235 | B | 235 | 225 | 215 | 205 | ||

Alloy No | Grade | Tensile strength (Mpa) | Elongation after fracture (%) | ||||

Thickness (mm) | |||||||

| ≤16 | >16--40 | >40--60 | >60--100 | |||

≥ | |||||||

|

|

|

|

|

|

| |

Q235 | B | 375--500 | 26 | 25 | 24 | 23 | |

Quality Assurance of Alloy Steel for Bearing

We are the ISO 9001:2000 authentication enterprises and we can provide the enterprise's quality written guarantee for all the exported products.

Certificate of quality is issued in English, in addition the normal terms, production process, the mechanical property (yield strength, tensile strength, elongation and hardness. forged ratio, UT test result, Grain size, heat treatment methods and the sample of is shown on the certificate of quality.

FAQ:

Q1 How soon can we receive the product after purchase?

A1 Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Images:

- Q: What are the standard sizes of steel angles?

- The standard sizes of steel angles can vary depending on the region and industry, but there are some common sizes that are widely used. In general, steel angles come in equal leg and unequal leg sizes. For equal leg angles, the standard sizes range from 20x20mm to 200x200mm, with thicknesses ranging from 3mm to 26mm. Unequal leg angles typically have one leg longer than the other, and their standard sizes range from 25x16mm to 200x150mm, with thicknesses ranging from 3mm to 15mm. These standard sizes are commonly used in construction, engineering, and manufacturing industries for various applications, such as structural supports, framing, and bracing. It's important to note that these sizes may vary depending on the specific requirements of a project or the standards set by the governing bodies within the industry.

- Q: Can steel angles be used in the construction of parking garages?

- Steel angles can indeed be utilized in the construction of parking garages. These angles are frequently employed in construction due to their robustness, durability, and versatility. They have a wide range of structural applications, including the building of parking garages. Steel angles offer support and reinforcement for crucial elements like beams and columns, as well as for framing and bracing. They play a significant role in establishing the framework for parking garage floors and walls, contributing stability and strength to the structure. Moreover, steel angles can be easily fabricated and tailored to meet the precise design and engineering specifications of a parking garage. All in all, steel angles are a favored choice for constructing parking garages because they can endure heavy loads, resist corrosion, and deliver enduring performance.

- Q: Can steel angles be used in transportation or infrastructure projects?

- Indeed, transportation or infrastructure projects can incorporate steel angles. Owing to their robustness and endurance, steel angles are frequently employed in construction. They are commonly utilized to furnish structural reinforcement and steadiness in a myriad of scenarios, including bridges, buildings, highways, and railways. In the realm of transportation projects, steel angles can be employed to fabricate vehicle ramps, guardrails, and frameworks for overhead signs. In infrastructure projects, they can be leveraged to erect retaining walls, foundations, and frameworks for utility installations. The adaptability and dependability of steel angles render them a favored option in these particular project types.

- Q: What are the common design codes and standards for steel angles?

- The common design codes and standards for steel angles depend on the specific application and industry requirements. However, some widely recognized design codes and standards applicable to steel angles include: 1. American Institute of Steel Construction (AISC): AISC provides design specifications and standards for structural steel construction, including angles. The AISC Steel Construction Manual offers guidance on the design of steel structures, including the selection and design of steel angles. 2. American Society for Testing and Materials (ASTM): ASTM International develops and publishes technical standards for various materials, including steel. ASTM A36/A36M is a commonly referenced standard for carbon structural steel, including angles. It specifies the requirements for chemical composition, mechanical properties, and testing methods. 3. European Norm (EN): The European Norm specifies technical delivery conditions for structural steel products. EN 10025-2 covers non-alloy structural steels, including angles, and provides requirements for chemical composition, mechanical properties, and tolerances. 4. British Standards Institution (BSI): The BSI publishes a range of standards relating to steel angles, including BS EN 10056-1, which details the dimensions and tolerances for hot-rolled equal and unequal steel angles. 5. Canadian Standards Association (CSA): CSA standards provide guidance for steel design and construction in Canada. CSA G40.21 is a widely used standard that covers the requirements for general structural steel, including angles. It is important to note that these are just some examples of the common design codes and standards for steel angles. Depending on the specific project and geographic location, there may be additional local or industry-specific codes and standards that need to be considered when designing and specifying steel angles. Consulting with a structural engineer or referring to the relevant design codes and standards is crucial to ensure compliance and safety in the design and construction of steel angles.

- Q: What are the tolerances for steel angles?

- The tolerances for steel angles can vary depending on the specific requirements and industry standards. However, common tolerances for steel angles typically include variations in dimensions, such as length, width, and thickness, within a certain range specified by the relevant standards or specifications. These tolerances ensure that the angles meet the required specifications and can be used effectively in various applications.

- Q: How do steel angles perform under cyclic or alternating loading conditions?

- Steel angles possess excellent performance characteristics under cyclic or alternating loading conditions because of their structural properties. The durability and high strength of steel are renowned, enabling angles to endure repeated loading without significant deformation or failure. Fatigue, a phenomenon that transpires when a material experiences recurring stress cycles, is observed in steel angles under cyclic loading. This leads to the accumulation of damage and potential failure over time. Nevertheless, steel has an exceptional fatigue strength compared to other materials, rendering it highly resistant to fatigue-induced failure. The performance of steel angles under cyclic loading is also influenced by their distinctive shape. The L-shaped configuration adds to their stability and ability to withstand bending or twisting forces. This form facilitates the dispersion of the load more evenly along the angle's length, reducing stress concentrations and enhancing its fatigue life. Moreover, steel angles can be reinforced using diverse techniques, such as heat treatment or surface hardening. These processes enhance the material's resistance to cyclic loading, making it even more proficient in enduring repeated stress cycles. In summary, steel angles are ideal for cyclic or alternating loading conditions due to their remarkable strength, durability, and fatigue resistance. Their L-shaped design and potential for reinforcement make them dependable structural components in various fields, encompassing construction, engineering, and manufacturing.

- Q: What are the different methods of connecting steel angles together?

- There are several different methods of connecting steel angles together, depending on the specific application and structural requirements. Some of the common methods include: 1. Welding: Welding is one of the most common and effective methods of connecting steel angles. It involves melting the edges of the angles and fusing them together using a welding electrode. This provides a strong and permanent connection. 2. Bolting: Bolting is another commonly used method to connect steel angles together. It involves using bolts, nuts, and washers to secure the angles in place. Bolting provides a strong connection that is easier to disassemble if needed. 3. Riveting: Riveting is a method that involves using metal pins called rivets to connect steel angles. It requires drilling holes in the angles and inserting the rivets, which are then hammered or pressed to create a permanent connection. 4. Adhesive bonding: Adhesive bonding is a method that involves using industrial adhesives to connect steel angles. It requires applying the adhesive to the surfaces of the angles and then pressing them together. Adhesive bonding provides a strong and durable connection that is also resistant to corrosion. 5. Mechanical connectors: Mechanical connectors, such as steel clips or brackets, can also be used to connect steel angles. These connectors are designed to provide a secure and rigid connection by clamping the angles together. It is important to choose the appropriate method based on factors such as the load-bearing requirements, structural design, and environmental conditions. Consulting with a structural engineer or a professional in the field is recommended to ensure the proper method is selected for the specific application.

- Q: Can steel angles be used in historical or heritage restoration projects?

- Historical or heritage restoration projects can indeed utilize steel angles. With their versatility, steel angles can serve various purposes, including structural support, reinforcing, and decorative detailing. By fabricating them to match the original design and materials of historical structures, seamless integration with the existing architecture can be achieved. Strength, durability, and resistance to corrosion are among the advantages that steel angles offer, making them particularly valuable in restoration projects that aim to preserve the historical integrity of the structure. Moreover, steel angles can be tailored and manufactured to meet specific project needs, making them suitable for a wide array of restoration applications.

- Q: Can steel angles be used in telecommunications tower constructions?

- Yes, steel angles can be used in telecommunications tower constructions. Steel angles are commonly used as structural components in various construction applications, including telecommunications towers. They provide strength, stability, and support to the tower structure. Steel angles can be welded or bolted together to form the framework of the tower, providing a sturdy and durable structure capable of withstanding the weight of the tower and its equipment. Additionally, steel angles can be easily fabricated and customized to meet the specific design and engineering requirements of the telecommunications tower.

- Q: Can steel angles be used in construction?

- Yes, steel angles can be used in construction. Steel angles are commonly used as structural elements in construction projects due to their strength, durability, and versatility. They are commonly used to support and reinforce various structures such as buildings, bridges, and industrial frameworks. Steel angles provide stability and structural integrity, making them a suitable choice for construction purposes.

Send your message to us

GB Standard High Quality Angle Bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords