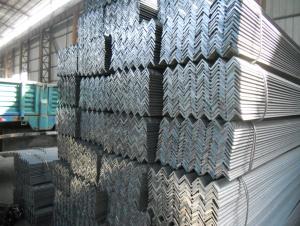

JIS Standard High Quality Angle Bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Angle Steel great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

According to the needs of different structures, Angle can compose to different force support component, and also can be the connections between components. It is widely used in various building structures and engineering structures such as roof beams, bridges, transmission towers, hoisting machinery and transport machinery, ships, industrial furnaces, reaction tower, container frame and warehouse etc.

Product Advantages:

OKorder's Angle Steelare durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

1. Invoicing on theoretical weight or actual weight as customer request

2. Length: 6m, 9m, 12m as following table

3. Sizes

Sizes: 25mm-250mm | ||

a*t | ||

25*2.5-4.0 | 70*6.0-9.0 | 130*9.0-15 |

30*2.5-6.6 | 75*6.0-9.0 | 140*10-14 |

36*3.0-5.0 | 80*5.0-10 | 150*10-20 |

38*2.3-6.0 | 90*7.0-10 | 160*10-16 |

40*3.0-5.0 | 100*6.0-12 | 175*12-15 |

45*4.0-6.0 | 110*8.0-10 | 180*12-18 |

50*4.0-6.0 | 120*6.0-15 | 200*14-25 |

60*4.0-8.0 | 125*8.0-14 | 250*25 |

Alloy No | Grade | Element (%) | |||||

C | Mn | S | P | Si | |||

|

|

|

|

|

|

| |

Q235 | B | 0.12—0.20 | 0.3—0.7 | ≤0.045 | ≤0.045 | ≤0.3 | |

|

|

|

|

|

|

| |

Alloy No | Grade | Yielding strength point( Mpa) | |||||

Thickness (mm) | |||||||

≤16 | >16--40 | >40--60 | >60--100 | ||||

≥ | |||||||

|

|

|

|

|

| ||

Q235 | B | 235 | 225 | 215 | 205 | ||

Alloy No | Grade | Tensile strength (Mpa) | Elongation after fracture (%) | ||||

Thickness (mm) | |||||||

| ≤16 | >16--40 | >40--60 | >60--100 | |||

≥ | |||||||

|

|

|

|

|

|

| |

Q235 | B | 375--500 | 26 | 25 | 24 | 23 | |

Payment:

-Invoicing on theoretical weight or actual weight as customer’s request.

-FOB, CFR or CIF.

-Regular terms of payment:

1, 30% payment in advance, the remaining balance (70% payment) against the copy of B/L. 100% payment before shipment.

2, 30% payment in advance, the remaining balance (70% L/C) against the copy of B/L. 100% payment before shipment.

3, Negotiable.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2 Can stainless steel rust?

A2 Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Images:

- Q: Can steel angles be used in electrical or telecommunications installations?

- Yes, steel angles can be used in electrical or telecommunications installations. Steel angles are commonly used as structural supports and mounting brackets in these types of installations due to their strength, durability, and versatility.

- Q: Can steel angles be used for fencing and gates?

- Absolutely, fencing and gates can indeed utilize steel angles. Steel angles have gained significant popularity in the realm of fencing and gate installations owing to their exceptional strength, durability, and versatility. These angles offer structural reinforcement and can be effortlessly welded or bolted together, resulting in robust and impregnable fencing or gate frameworks. Moreover, steel angles possess remarkable resistance against weathering and corrosion, rendering them ideal for outdoor applications. Furthermore, they can be tailored to various lengths, heights, and designs, thereby allowing for boundless possibilities in creating diverse fence and gate styles. In conclusion, steel angles serve as a dependable and efficient material for all fencing and gate ventures.

- Q: Can steel angles be used in automotive chassis construction?

- Indeed, the utilization of steel angles is possible in the construction of automotive chassis. Steel angles, also referred to as angle irons, are widely employed in the construction industry due to their strength and versatility. In the specific context of automotive chassis construction, steel angles can serve the purpose of providing structural support and reinforcement to the chassis frame. Vehicle chassis frameworks are frequently formed using steel angles, as they offer a stable and rigid structure. These angles can be utilized in the creation of primary longitudinal and cross members, as well as other essential structural components. Utilizing steel angles in automotive chassis construction presents numerous advantages. Firstly, steel is a robust and long-lasting material, enabling it to withstand the various stresses and loads experienced by the chassis. Additionally, steel angles can be easily fabricated and welded, granting flexibility in design and customization. Furthermore, steel angles are cost-effective in comparison to alternative materials like aluminum or carbon fiber. This cost-efficiency makes them a favored choice in automotive chassis construction, particularly for mass-produced vehicles where cost optimization is vital. Nevertheless, it is crucial to consider the specific requirements and regulations of the automotive industry when utilizing steel angles in chassis construction. Chassis designs must adhere to certain safety standards, encompassing crashworthiness and structural integrity. Thus, it is essential to ensure that the selected steel angles and their dimensions are suitable for the intended application and comply with relevant regulations. In conclusion, the incorporation of steel angles in automotive chassis construction is indeed feasible. Their strength, versatility, cost-effectiveness, and ease of fabrication render them a suitable option for establishing the framework of a vehicle's chassis. Nonetheless, it is vital to contemplate safety regulations and ascertain that the chosen steel angles meet the required standards.

- Q: Can steel angles be used for shelving units?

- Yes, steel angles can be used for shelving units. Steel angles are commonly used in construction and industrial applications due to their strength and durability. They provide excellent structural support and can withstand heavy loads, making them ideal for shelving units that need to hold a significant amount of weight. Additionally, steel angles are versatile and can be easily customized to fit various shelving designs and configurations. Whether for home, office, or commercial use, steel angles are a reliable choice for creating sturdy and long-lasting shelving units.

- Q: How do steel angles perform in earthquake-prone regions?

- Steel angles perform well in earthquake-prone regions due to their high strength and flexibility. They are commonly used in structural systems to resist lateral forces and provide stability during seismic events. The angular shape of the steel angles helps in distributing the seismic forces effectively, reducing the risk of structural failure. Additionally, steel's ductility allows it to bend without fracturing, further enhancing its performance in earthquake-prone areas.

- Q: How do you join steel angles together?

- One common method to join steel angles together is by using welding techniques. This involves heating the joint area to a high temperature and fusing the angles together using a welding electrode or filler material. Welding creates a strong and durable bond between the steel angles, ensuring structural integrity.

- Q: What is the standard size of steel angles?

- Steel angles come in a range of sizes that vary depending on the region and industry standards. Generally, they are available in equal and unequal leg lengths, with the equal leg angles typically sized between 20mm and 200mm. The thickness of the angle can also vary, typically falling between 3mm and 20mm. However, it is crucial to understand that these measurements may differ based on the specific application or project requirements. To determine the correct size of steel angles for a particular project, it is recommended to consult industry standards or manufacturers.

- Q: What are the different types of steel angles connections for mezzanine floors?

- There are several different types of steel angle connections that can be used for mezzanine floors. These connections are designed to provide structural stability and support for the floor, ensuring that it can safely accommodate the intended loads and usage. 1. Bolted Connections: Bolted connections are commonly used in mezzanine floors as they offer a strong and secure connection. These connections involve using bolts to attach the steel angles together, creating a rigid and stable framework. Bolted connections can be easily adjusted or disassembled if required. 2. Welded Connections: Welded connections involve joining the steel angles using welding techniques. This type of connection provides a permanent and strong bond between the angles, ensuring maximum stability. Welded connections are often preferred for heavy-duty mezzanine floors where high load-bearing capacity is required. 3. Clip Connections: Clip connections are a popular choice for mezzanine floors as they offer ease of installation and flexibility. These connections involve using metal clips or brackets to secure the steel angles together. Clip connections can be easily adjusted or disassembled, allowing for future modifications or reconfigurations of the mezzanine floor layout. 4. Gusset Plate Connections: Gusset plate connections involve using additional steel plates, known as gusset plates, to reinforce the joint between the steel angles. These plates are typically welded or bolted to the angles, providing added strength and stability to the connection. Gusset plate connections are commonly used in mezzanine floors where extra reinforcement is necessary. 5. Cleat Connections: Cleat connections involve using a cleat plate to connect two steel angles. The cleat plate is attached to one angle, while the other angle is bolted or welded to the plate. This type of connection provides a strong and secure joint, particularly when used with heavy-duty mezzanine floors. It is essential to ensure that the chosen steel angle connections for mezzanine floors are in compliance with local building codes and regulations. Additionally, consulting a structural engineer or a professional with expertise in mezzanine floor construction is recommended to ensure the connections are designed and installed correctly for optimal safety and performance.

- Q: How do steel angles compare to other structural materials like wood or aluminum?

- Steel angles have several advantages over other structural materials like wood or aluminum. Firstly, steel angles are much stronger and more durable than wood or aluminum. They have a high strength-to-weight ratio, meaning they can support heavy loads while being relatively lightweight themselves. This makes steel angles ideal for applications requiring structural support or load-bearing capabilities. Secondly, steel angles are extremely resistant to environmental factors such as corrosion and fire. Unlike wood, which is susceptible to rot and decay, and aluminum, which can corrode when exposed to moisture or chemicals, steel angles can withstand harsh conditions and maintain their structural integrity over time. This makes them suitable for outdoor and industrial applications. Additionally, steel angles offer greater versatility and flexibility in design and construction. They can be easily shaped, welded, and manipulated to meet specific project requirements. This allows for greater creativity and customization in architectural and engineering projects. Moreover, steel angles have a longer lifespan compared to wood or aluminum. They require minimal maintenance and have a lower likelihood of needing repair or replacement, reducing long-term costs. This durability, combined with their superior strength, makes steel angles a cost-effective choice in the long run. However, it's worth noting that steel angles may be more expensive upfront compared to wood or aluminum. They also require specialized equipment and expertise for installation. Additionally, steel is a conductor of heat and electricity, so proper insulation or grounding may be necessary in certain applications. In summary, steel angles offer superior strength, durability, resistance to environmental factors, and design flexibility compared to wood or aluminum. While they may have a higher initial cost and require specialized installation, their long lifespan and cost-effectiveness make them a preferred choice for many structural applications.

- Q: What are the alternatives to steel angles in construction?

- Some alternatives to steel angles in construction include aluminum angles, fiberglass angles, and plastic angles. These materials offer different properties such as lightweight, corrosion resistance, and flexibility, making them suitable for various construction applications.

Send your message to us

JIS Standard High Quality Angle Bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords