SS400 Hot Rolled Steel Coil in Sheets First Grade

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

SS400 Hot Rolled Steel Coil in Sheets First Grade

Detailed Information of SS400 Hot Rolled Steel Coil in Sheets First Grade

| C | Si | P | S | yield Strength MAp | Tensile strength MAp | Elongation % | ||

| A36 | 0.24 | 0.4 | 0.045 | 0.03 | 250 | 400-520 | 26 | |

| C | Si | Mn | P | S | Cu | |||

| A283 | ≤0.27 | 0.15-0.4 | ≤0.9 | ≤0.035 | ≤0.04 | ≥0.2 | ||

| Thickness: | 6mm, 8mm, 12mm, 16mm, 20mm, 25mm, 30mm, 50mm, 80mm, 100mm, 150mm, 200mm | |||||||

| Width: | 1500mm, 1800mm, 2000mm, 2200mm, 2500mm | |||||||

| Length: | 6000mm, 8000m, can cut to width and length | |||||||

| Packing Details; | according to customer‘s require or export’s standard | |||||||

| Delivery time; | 7 days for stock sizes, 20-25 days for new production sizes | |||||||

| Port: | Tianjin China | |||||||

Related Products Overviews of SS400 Hot Rolled Steel Coil in Sheets First Grade

Product Name | Typical Grades | Diameter(mm) | Standard Adopted |

Carbon Steel | 20 (1020/S20C/C22) |

Ø16-Ø300 |

GB/SAE/ JIS/DIN |

40 (1040/S40C/C40) | |||

45 (1045/S45C/C45) | |||

Bearing Steel | GCr9 (51100/SUJ1) |

Ø12-Ø250 | |

GCr15 (52100/SUJ2/100Gr6) | |||

GCr9SiMn (A485-Gr.1/SUJ3) | |||

Cr-Mo Steel | 20Cr (5120/SCr420H/20Cr4) |

Ø12-Ø250 | |

40Cr (5140/SCr440/41Cr4) | |||

42CrMo(4140/SCM440/42CrMo4) | |||

Gear Steel | 20CrNiMo |

Ø16-Ø600 | |

20CrMn(5115/SMnC420/20MnCr5) | |||

20CrNiMo(8620/SNCM220/20CrMiMo2) |

Related Products Application of SS400 Hot Rolled Steel Coil in Sheets First Grade

Carbon Steel | l Mold bottom l Plastic mold l Construction machinery parts l Automobile parts l Security grills l Screens l Construction |

Bearing Steel | l Aerospace l Navigation l Nuclear energy l Chemical industry l Electronic information l Petrochemical l Instrument and meter l Transportation |

Cr-Mo Steel | l Mechanism & Fasteners gear l Stressed components for vehicles l Engines and machines l Parts of larger cross-section |

Gear Steel | l All kinds of gears l Statically and dynamically stressed component for vehicles l Engines and machine l Larger cross-section parts l Crankshafts |

Company Introduction of SS400 Hot Rolled Steel Coil in Sheets First Grade

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

After-sale service | l CNBM provides the services and support you need for every step of our cooperation. We’re the business partners you can trust; you can relax and get on with doing business. l For any problem, please kindly contact us at any your convenient time, we’ll reply you in our first priority within 24 hours

|

Advantages

| l Industry experience over 20 years. l Shipment of goods -More than 70 countries worldwide. l The most convenient transport and prompt delivery. l Competitive price with best service. l High technical production line with top quality products. l High reputation based on best quality products.

|

Packaging & Delivery of SS400 Hot Rolled Steel Coil in Sheets First Grade

Packaging Detail | Sea worthy packing /as per customer's packing instruction |

Delivery Detail | 15 ~ 40 days after receiving the deposit |

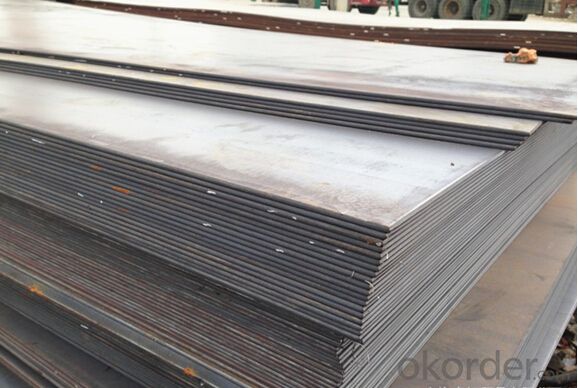

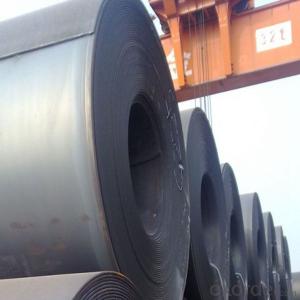

Products Show

FAQ:

Are you a trading company or manufacturer? | Manufacturer |

What’s the MOQ? | 3 metric ton |

What’s your delivery time? | 15-35 days after downpayment received |

Do you Accept OEM service? | Yes |

what’s your delivery terms? | FOB/CFR/CIF |

What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

Western Union acceptable for small amount. | |

L/C acceptable for large amount. | |

Scrow ,Paybal,Alipay are also ok | |

Why choose us? | Chose happens because of quality, then price, We can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. |

What's your available port of Shipment? | Main Port, China |

What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust

|

Where are your Market? | Covering more than 160 countries in the world |

- Q: How is special steel used in the production of engine components?

- Special steel is used in the production of engine components due to its high strength, durability, and resistance to heat and corrosion. It is commonly used for manufacturing pistons, crankshafts, valves, and connecting rods, ensuring the engine's optimal performance and longevity. Additionally, special steel's ability to withstand extreme temperatures and stress makes it an ideal choice for critical engine parts, enabling them to function efficiently under demanding conditions.

- Q: How is shock-resistant alloy steel used in the production of impact-resistant parts?

- Shock-resistant alloy steel is used in the production of impact-resistant parts due to its high strength and ability to withstand sudden impact forces without fracturing or deforming. This steel is specifically designed to absorb and disperse energy, making it ideal for applications where parts are exposed to repeated impacts or high-stress environments. By using shock-resistant alloy steel, manufacturers can create durable and reliable impact-resistant parts that can withstand heavy loads, reduce the risk of failure, and increase the overall safety and longevity of the component or equipment.

- Q: What are the factors affecting the cost of special steel?

- The cost of special steel can be influenced by various factors. The price of raw materials is one of the primary factors. Special steel often requires specific alloys or additives, which can be expensive to obtain. Any fluctuations in the prices of these raw materials can directly affect the final product's cost. Another factor is the complexity of the manufacturing process. Advanced techniques and machinery are often used to produce special steel, and acquiring and maintaining them can be costly. The more intricate and specialized the manufacturing process, the higher the steel's cost. The demand and supply dynamics also play a role in determining the cost of special steel. If there is high demand but limited supply, the price is likely to go up. Conversely, if there is low demand and excessive supply, the price may decrease. Moreover, the level of customization required for the special steel can impact its cost. If a customer needs specific dimensions, tolerances, or surface finishes, additional processing steps may be necessary, leading to higher costs. Furthermore, transportation and logistics costs can affect the overall cost of special steel. If the steel needs to be transported over long distances or requires specialized handling, these additional expenses can accumulate. Lastly, market conditions and economic factors can influence the cost of special steel. Inflation, currency exchange rates, and overall economic stability can all have an impact on the pricing of special steel. In conclusion, the cost of special steel is determined by a combination of factors, including raw material costs, manufacturing complexity, demand and supply dynamics, customization requirements, transportation and logistics costs, and market conditions.

- Q: How does special steel contribute to reducing greenhouse gas emissions?

- Special steel can contribute to reducing greenhouse gas emissions in several ways. Firstly, it can be used in the manufacturing of more energy-efficient vehicles, which emit lower levels of carbon dioxide during operation. Additionally, special steel can be utilized in the production of renewable energy infrastructure, such as wind turbines and solar panels, which helps reduce reliance on fossil fuels. Furthermore, special steel is often employed in the construction of energy-efficient buildings, which require less energy for heating and cooling, thus lowering overall emissions. Overall, the use of special steel in various applications plays a significant role in the reduction of greenhouse gas emissions and the transition to a more sustainable future.

- Q: What are the different shot blasting techniques used for special steel?

- Some of the different shot blasting techniques used for special steel include wheel blasting, air blasting, and wet blasting. Wheel blasting involves using a high-speed rotating wheel to propel steel shot at the surface of the steel, removing any contaminants or rust. Air blasting uses compressed air to propel abrasive particles at high speed onto the surface of the steel, achieving a similar result. Wet blasting combines water with the abrasive particles to create a slurry, which is then sprayed onto the steel surface to remove any impurities effectively. These techniques are commonly employed to prepare special steel for further processing or to enhance its surface finish.

- Q: What are the common alloying elements in special steel?

- The common alloying elements in special steel are chromium, manganese, molybdenum, nickel, and vanadium.

- Q: How is special steel used in toolmaking?

- Due to its exceptional properties, special steel is widely utilized in toolmaking to create durable and high-performance tools. Various tools, including drills, saws, cutting tools, dies, and molds, are manufactured in toolmaking. The purpose of incorporating special steel in toolmaking is to guarantee that these tools possess the necessary strength, hardness, toughness, and wear resistance needed for their intended applications. The primary advantage of special steel in toolmaking is its high strength. This is achieved by alloying special steel with elements such as chromium, molybdenum, vanadium, and tungsten, which enhance its strength and hardness. Consequently, the tools can endure heavy loads, resist deformation, and maintain their structural integrity even under extreme working conditions. In addition to strength, special steel also exhibits excellent hardness. Heat treatment processes like quenching and tempering are applied to tools made from special steel to achieve the desired hardness level. This hardness is crucial in toolmaking as it allows the tools to efficiently cut, drill, or shape various materials without succumbing to damage or wear easily. Furthermore, special steel possesses exceptional toughness. Toughness refers to a material's ability to absorb energy and resist cracking or fracturing. Tools made from special steel can withstand impact and heavy loads, ensuring that they remain intact and do not chip easily during use. This is of utmost importance in toolmaking as tools often encounter high-stress situations where toughness is essential to prevent premature failure. Another significant advantage of special steel in toolmaking is its excellent wear resistance. Constant friction, abrasion, and contact with hard materials subject tools to wear and tear. Special steel is designed specifically to resist wear, allowing the tools to maintain their cutting or shaping abilities over prolonged periods. Consequently, the tool's lifespan is extended, ensuring consistent performance and high-quality output. Special steel is also renowned for its corrosion resistance, which is advantageous in toolmaking, especially when working with corrosive materials or in harsh environments. The inclusion of certain elements like chromium in special steel enhances its resistance to corrosion, preventing rust and deterioration of the tools. In conclusion, special steel is an indispensable material in toolmaking as it provides the necessary strength, hardness, toughness, wear resistance, and corrosion resistance. These properties enable tools to perform effectively and efficiently, ensuring durability and longevity. Whether it is for cutting, drilling, shaping, or molding, special steel is essential in producing high-quality tools that meet the demands of various industries.

- Q: How is special steel used in the mining supply chain?

- Special steel is used extensively in the mining supply chain due to its exceptional strength, durability, and resistance to corrosion. It is utilized in various equipment and machinery used for exploration, extraction, processing, and transportation of minerals. Special steel is commonly employed in mining tools, drill bits, conveyor systems, crushers, grinding mills, and pumps, ensuring efficient and reliable operations in challenging mining environments.

- Q: How does special steel perform in cryogenic corrosion resistance?

- Special steels possess exceptional capabilities in terms of resisting corrosion in cryogenic environments. Unlike regular steels, which tend to become brittle and prone to corrosion when exposed to extremely low temperatures, special steels are specifically engineered to endure such conditions while maintaining their mechanical properties and corrosion resistance. The remarkable performance of special steels in cryogenic settings can be primarily attributed to their composition and microstructure. These steels are typically infused with elements like nickel, molybdenum, and nitrogen, which significantly enhance their ability to withstand corrosion at low temperatures. Additionally, the microstructure of special steels is meticulously controlled, resulting in a fine grain size and a uniform distribution of alloying elements. This microstructure contributes to the steel's capacity to resist corrosion and retain its mechanical strength even in cryogenic temperatures. Furthermore, special steels undergo rigorous testing procedures to ensure their suitability for cryogenic applications. They are subjected to low-temperature impact tests, which evaluate their toughness and resistance to brittle fracture. These tests verify that the steel can endure the stresses and strains imposed by cryogenic conditions without experiencing failure. In conclusion, special steels exhibit exceptional resistance to cryogenic corrosion due to their distinct composition, microstructure, and comprehensive testing. They are the preferred choice for applications that demand reliable performance in extremely low temperatures, such as in the aerospace, energy, and scientific research industries.

- Q: What are the different methods for improving the heat resistance of special steel?

- There are several methods for improving the heat resistance of special steel. These methods include: 1. Alloying: One of the most common methods is to alloy the steel with certain elements that enhance its heat resistance. For example, the addition of chromium, nickel, or molybdenum can significantly improve the steel's ability to withstand high temperatures. 2. Heat treatment: Heat treatment processes such as annealing, quenching, and tempering can be employed to enhance the heat resistance of special steel. These processes help in refining the microstructure of the steel and improving its mechanical properties, including heat resistance. 3. Surface modification: Applying specialized coatings or surface treatments can also improve the heat resistance of special steel. For instance, processes like nitriding, carburizing, or ceramic coating can create a protective layer on the surface of the steel, preventing oxidation and improving its ability to withstand high temperatures. 4. Grain refinement: Controlling the grain size of the steel through processes like grain refinement or recrystallization can enhance its heat resistance. Smaller grain sizes reduce the diffusion of atoms within the material, making it more resistant to high temperatures. 5. Precipitation hardening: Precipitation hardening is a technique where small particles are formed within the steel matrix, strengthening the material and improving its resistance to heat. This method involves a specific heat treatment process that enables the formation of these particles. 6. Controlled cooling: Optimizing the cooling process after heat treatment can also improve the heat resistance of special steel. By controlling the cooling rate, the formation of undesirable phases or microstructural defects can be minimized, ensuring better heat resistance. 7. Material selection: Choosing the right type of special steel with inherently high heat resistance properties is another method for improving heat resistance. For example, stainless steel, tool steel, or superalloys are known for their excellent heat resistance and are often selected for applications where high temperatures are involved. It is worth noting that the selection of the appropriate method or combination of methods for improving heat resistance depends on the specific requirements and constraints of the application.

Send your message to us

SS400 Hot Rolled Steel Coil in Sheets First Grade

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords