Prime Hot Rolled Steel Sheets in Coils SS400 Grade

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 23 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Descriptions:

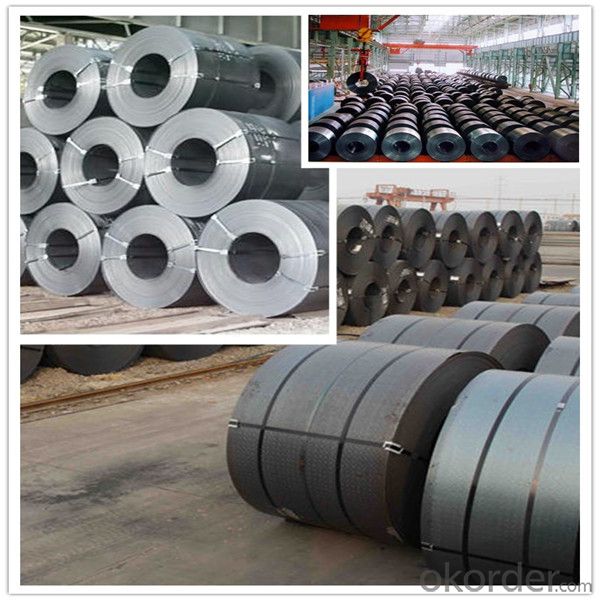

1,Product Name: SS400 Prime Quality Hot Rolled Steel Coil

2,Thickness: 1.8mm-20mm

3,Width:1000mm-1600mm

4,Length: according to coil weight

5,Minimun order: 23 mt

6,Packaging Details: Fully seaworthy export packing

7,Price Terms:Fob,CIF,CF

8.Terms of payment: L/C at sight

9.Coil weight: 23 mt or client's suggestion

10.Width tolerance: ±10mm

Product Photo:

Packing/Shipping Details:

| Delivery time | 20-35days after receiving the payment of 30% deposit. |

| Payment | -Irrevocable L/C at sight. |

| -30% T/T in advance and 70% balance against copy of B/L. | |

| Packing | -Standard Export Packing |

| -According to customer's request. | |

| Load port | Tianjin port, Shanghai port, Ningbo port or customer's request |

| Feedback | If you have any questions, please feel free to contact us at any time possible. |

| We will reply as soon as possible. | |

| After Sale | Any questions of the production, please let me know directly by email or phone. |

| We can deal with these issues on time, promise give you happy answers. | |

| We focused on the after sale. Welcome send any comments to us. |

Our Service:

1.Best competitive price with high quality.

2.Your inquiry will be replied in 24 hours.

3.Well-trained and experienced team.

4.Protection of your sales area.

- Q: What are the different types of steel coil packaging techniques?

- There are several types of steel coil packaging techniques, including banding, strapping, shrink wrapping, and palletizing. Banding involves securing the coil with metal bands, while strapping uses plastic or steel straps. Shrink wrapping involves wrapping the coil with plastic film and applying heat to shrink it tightly. Palletizing involves stacking the coils on a pallet and securing them with stretch wrap or straps. These techniques help protect the coils during transportation and storage.

- Q: were iron age weapons made of steel?

- No, the iron age was just iron. It was smelted down in open fires where temperatures can vary. There was a problem of not always being able to cook out all the impurities from the ore, which led to inconsistent strengths in finished products. People first discovered the properties and advantages of steel when charcoal (carbon) was added to smelted iron. I don't know when the first steel was made. But it must have been a more expensive process because it didn't appear in household products until around 1800. But I'm not sure on that.

- Q: it seems like the hardness of Stainless steel, i saw 410c stainless stell, i saw 440c stainless steel, what does it means anyway?

- 440c Stainless

- Q: Can steel coils be used in architectural applications?

- Architectural applications can indeed utilize steel coils. These coils possess versatility and can be transformed into various shapes and forms to match the distinctive design specifications of architectural ventures. They find utility in constructing structures such as buildings, bridges, and more, as well as in fabricating architectural elements like roofing, cladding, and facades. The utilization of steel coils in architectural applications presents several benefits. They exhibit exceptional durability, strength, and corrosion resistance, rendering them suitable for constructing enduring and low-maintenance structures. Steel coils can be customized in terms of thickness, width, and surface finish, granting architects the ability to achieve their desired aesthetic and functional objectives. Moreover, steel coils are renowned for their structural stability and load-bearing capacity, both of which are vital considerations in architectural designs. Their high strength-to-weight ratio makes them an ideal selection for creating spacious and open interior areas, as well as for supporting heavy loads in multi-story buildings. Additionally, steel coils are easily fabricated and installed, resulting in time and labor savings during the construction process. They can be efficiently molded, cut, and welded to create intricate shapes or architectural details. Additionally, steel coils can be pre-fabricated off-site, guaranteeing precision and quality control, and subsequently assembled on-site, reducing construction time and minimizing disruptions to the surrounding environment. All in all, steel coils present architects and designers with a wide array of possibilities in architectural applications. Whether it pertains to structural support, aesthetic appeal, or functional requirements, steel coils provide a dependable and versatile material option that can fulfill the demands of contemporary architectural projects.

- Q: How are steel coils used in the production of pressure vessels?

- Steel coils are used in the production of pressure vessels as they provide a strong and durable material for constructing the vessel's shell. The coils are formed into cylindrical shapes and welded together to create the vessel's body. This ensures that the vessel can withstand the high pressures it is designed to hold, making steel coils an essential component in pressure vessel manufacturing.

- Q: I have a Victorinox Pioneer, and I recently filed a little metal off the blade for some jimping. Is the already stainless steel blade still stainless?

- Yes, stainless steel is stainless all the way through. All metals are uniform in composition throughout the piece. However, many metal items are plated to give a different finish from the base metal or to provide protection. An example is galvanized ductwork. The duct is made of steel, but a coating of zinc is plated onto it for corrosion resistance. Likewise, some items are made of steel or brass, but are chrome plated to present a bright, shiny appearance.

- Q: I bought a stainless steel mood ring two days ago, but would it rust?Thanks in advance!

- Stainless Steel does not rust...that is why it is used in our kitchens and the top kitchens of the world...!! sorry...Stainless Steel does not Tarnish either!

- Q: Is this a strong, durable piece of steel that can take abuse? I'm thinking about using it on a small project.

- Hey Ramzi, I met this chick and was wondering if you could tell me if she would make a good wife. Here's your answer: Big Blue, there are a hundred bits of information I would need, and even then there are mysterious factors that affect the outcome. So basically, I don't have the slightest idea. My answer to your question is exactly the same. Without showing exactly how the Simpson Tie is being used, there is obviously no way to know if it is suitable. Can it be tempered? Sure, but again, I give it a 99% likelihood it will not help in your application. Explain it in detail in 5 to 10 sentences. Give us diagrams and photos. If you can't or won't do that, here's Plan B. Head over to your nearest machine shop, and ask the machinist what he thinks. He will ask the probing questions to understand the needs of the part. It is likely a Simpson Tie won't do it but he is in a good position to suggest a workable approach, and then sell it to you. By the way, if this is a load-supporting member of a motorcycle or some other fast moving vehicle, be prepared to get kicked out of the machine shop. The risk of making an error is high and the outcome extremely dangerous. I would not risk a million dollar lawsuit in order to sell you a $10 part.

- Q: i am working a client.my vendor specified in pipe specification pipe line class as MS1 (code for Mild steel)but assigned material to this code is cs smls astm A 106B.my question is any difference between CS and MS material?pls suggest me

- *Carbon steel, also called plain carbon steel or Mild Steel, is steel where the main alloying constituent is carbon. The AISI defines carbon steel as: Steel is considered to be carbon steel when no minimum content is specified or required for chromium, cobalt, columbium, molybdenum, nickel, titanium, tungsten, vanadium or zirconium, or any other element to be added to obtain a desired alloying effect; when the specified minimum for copper does not exceed 0.40 percent; or when the maximum content specified for any of the following elements does not exceed the percentages noted: manganese 1.65, silicon 0.60, copper 0.60. If it crosses limit as said, it will come under alloy steel. ASTM A 106 gr B is a carbon steel pipe and seamless Pipe for High Temperature Service. So, it will be a mild steel comes under carbon steel category.

- Q: How are steel coils inspected for surface defects using non-destructive testing methods?

- To ensure the quality and integrity of steel coils, non-destructive testing (NDT) methods are employed to inspect them for surface defects. Several common NDT methods are utilized in this process. Visual inspection is one of the most widely used methods, where trained inspectors visually examine the steel coils for visible defects like scratches, cracks, pits, or corrosion. Although this method is simple and cost-effective, it can only detect surface-level defects. Magnetic particle testing (MT) is another commonly used NDT method. It utilizes magnetism to identify surface and near-surface defects in ferromagnetic materials like steel. By applying a magnetic field and iron particles to the steel coil, any defects such as cracks or discontinuities become visible as the iron particles concentrate around them. Liquid penetrant testing (PT) is a different NDT method used for inspecting steel coils. It involves applying a liquid penetrant to the coil's surface, which is drawn into surface defects through capillary action. After removing excess penetrant and applying a developer, the defects become visible as the developer draws out the penetrant. Ultrasonic testing (UT) is widely used to detect both surface and subsurface defects in steel coils. It transmits high-frequency sound waves into the coil and analyzes the reflected waves to identify abnormalities. This method can detect defects like cracks, inclusions, and voids that may not be visible to the naked eye. Additionally, eddy current testing (ECT) is another NDT method for inspecting steel coils. It utilizes electromagnetic induction to detect surface and near-surface defects. By placing a coil carrying an alternating current near the surface of the coil being inspected, any changes in the coil's electrical conductivity caused by surface defects are detected and analyzed to identify and evaluate their severity. In summary, various non-destructive testing methods such as visual inspection, magnetic particle testing, liquid penetrant testing, ultrasonic testing, and eddy current testing are utilized to inspect steel coils for surface defects. These methods ensure the quality and integrity of the steel coils before they are used in various applications.

Send your message to us

Prime Hot Rolled Steel Sheets in Coils SS400 Grade

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 23 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords