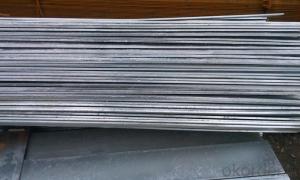

Square Bar

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

1.Heat the EVA film

2.Cover the heated EVA film on the mould(can be made from wood or aluminum)

3.Spray a coating in a certain baume degree

4.Put on the empty blask

5.Sand-up the flask and vibrate to compaction

Packaging & Delivery

Packaging Details:containers

Delivery Detail:Complete one set of equipment needs for three months

- Q: What are the common types of steel products used in the marine industry?

- The common types of steel products used in the marine industry include structural steel, marine grade stainless steel, and steel plates for shipbuilding.

- Q: How are steel beams used in construction?

- Steel beams are commonly used in construction to provide structural support and stability to buildings and infrastructure. They are often used as load-bearing elements in the construction of walls, floors, and roofs, and they can also be used as columns or braces. Steel beams are preferred due to their high strength, durability, and versatility, allowing for the construction of larger, more complex structures.

- Q: What are the applications of steel in the food processing industry?

- Steel is widely used in the food processing industry due to its durability, hygiene, and resistance to corrosion. It is utilized in various applications such as food storage containers, processing equipment, conveyor belts, and cutting tools. Steel's ability to withstand high temperatures and easy cleaning make it ideal for maintaining food safety standards and ensuring the efficiency of food processing operations.

- Q: How are steel plates used in the fabrication of storage silos?

- Steel plates are used in the fabrication of storage silos as they provide the necessary strength and durability to withstand the weight and pressure of stored materials. These plates are shaped, welded, and bolted together to create a sturdy structure that can safely hold and store a variety of goods, such as grains, liquids, or bulk materials.

- Q: What are the factors to consider when selecting the right type of steel for a specific application?

- When selecting the right type of steel for a specific application, several factors need to be considered. These factors include the required strength and hardness of the steel, its corrosion resistance properties, the temperature and environment in which it will be used, the desired formability and weldability, as well as cost considerations. Additionally, factors such as the required size and shape of the steel, its machinability, and any specific industry standards or regulations that need to be met should also be taken into account. Ultimately, selecting the right type of steel involves evaluating all these factors to ensure that it meets the specific requirements of the application in terms of performance, durability, and cost-effectiveness.

- Q: What are the applications of steel gratings in wastewater treatment plants?

- Steel gratings are commonly used in wastewater treatment plants for various applications. They are primarily used as floor grating in walkways and platforms to provide a safe and stable surface for workers to access different areas of the plant. Additionally, steel gratings are used for trench covers, allowing easy access to underground pipes and channels for maintenance and inspection purposes. They also find application in the construction of drainage channels to efficiently collect and transport wastewater. The durability and strength of steel gratings make them ideal for withstanding the harsh and corrosive environment commonly found in wastewater treatment plants.

- Q: What are the different types of steel bolts and their uses in the automotive aftermarket?

- There are several different types of steel bolts commonly used in the automotive aftermarket. Some of the most common types include hex bolts, flange bolts, carriage bolts, and socket head cap bolts. Hex bolts are the most widely used type of bolt and are typically used for general-purpose applications. They have a hexagonal head and require a wrench or socket for tightening. Flange bolts have a built-in washer under the head, which helps distribute the load and provide a more secure connection. These bolts are often used in applications where vibration or movement is a concern. Carriage bolts have a round, domed head and a square or ribbed neck under the head. They are commonly used in applications where a smooth finish is desired, such as attaching decorative accessories or trim. Socket head cap bolts have a cylindrical head with a socket drive and are commonly used in applications where a low-profile, flush finish is desired. These bolts are often used in engine components, suspension systems, and other areas where space is limited. Each type of steel bolt has its own specific uses in the automotive aftermarket, depending on factors such as load requirements, vibration resistance, and desired finish. It is important to choose the appropriate type of bolt for each application to ensure proper functionality and safety.

- Q: What are the different types of steel forgings and their uses?

- There are several types of steel forgings, each with its own unique properties and uses. Some common types include open-die forgings, closed-die forgings, and seamless rolled ring forgings. Open-die forgings are used for large and complex parts, such as turbine shafts and pressure vessels. Closed-die forgings are ideal for smaller and intricate components like automotive parts and hand tools. Seamless rolled ring forgings are commonly used in applications requiring high strength and durability, such as gears, bearings, and flanges. Overall, steel forgings offer superior strength, reliability, and resistance to wear, making them essential in various industries including aerospace, automotive, and oil and gas.

- Q: What are the common types of steel products used in the textile industry?

- Some common types of steel products used in the textile industry include steel wires, steel pins, steel needles, and steel hooks. These products are used for various purposes such as fabric weaving, sewing, fastening, and hanging materials in textile machinery.

- Q: What are the different types of steel roofing systems?

- There are several different types of steel roofing systems available, including standing seam, corrugated, and stone-coated steel. Each type offers its own unique benefits and aesthetic appeal.

Send your message to us

Square Bar

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords