Hot Rolled Steel Square Bars Q235,A36,S235JR, SS400

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Hot Rolled Steel Square Bars Q235,A36,S235JR, SS400 at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

-The Square Steel is normally used as structure steel.

-Row material for other structure steel like steel angles, channels, I-beams, H-beams, etc…

-Row material for steel pipes.

Product Advantages:

Hot Rolled Steel Square Bars Q235,A36,S235JR, SS400 are durable, strong, and resists corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (7-10 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

-Standard: GB,

-Grade: Q235 or equivalent.

Chemical Composition:

Standard | Grade | Element (%) | ||||

GB | Q235B | C | Mn | S | P | Si |

0.12~0.20 | 0.30~0.70 | ≤0.045 | ≤0.045 | ≤0.30 | ||

Measures of Hot Rolled Square Bar:

(Section of HR Square Bar)

-Length of a side and Theoretical weight of Square Bar.

Length of a side(mm) | Theoretical weight(kg/m) | Length of a side(mm) | Theoretical weight(kg/m) |

6 | 0.283 | 32 | 8.04 |

7 | 0.385 | *33 | 8.55 |

8 | 0.502 | 34 | 9.07 |

9 | 0.636 | *35 | 9.62 |

10 | 0.785 | 36 | 10.17 |

11 | 0.950 | 38 | 11.24 |

12 | 1.13 | 40 | 12.56 |

13 | 1.33 | 42 | 13.85 |

14 | 1.54 | 45 | 15.90 |

15 | 1.77 | 48 | 18.09 |

16 | 2.01 | 50 | 19.63 |

17 | 2.27 | 53 | 22.05 |

18 | 2.54 | *55 | 23.6 |

19 | 2.82 | 56 | 24.61 |

20 | 3.14 | *58 | 26.4 |

21 | 3.46 | 60 | 28.26 |

22 | 3.80 | 63 | 31.16 |

*23 | 4.15 | *65 | 33.17 |

24 | 4.52 | *68 | 36.3 |

25 | 4.91 | 79 | 38.49 |

26 | 5.30 | 75 | 44.16 |

*27 | 5.72 | 80 | 50.24 |

28 | 6.15 | 85 | 56.72 |

*29 | 6.60 | 90 | 63.59 |

30 | 7.06 | 95 | 70.85 |

*31 | 7.54 | 100 | 78.50 |

Notes:

1, The theoretical weights in the list, base on the density of 7.85 g/cm3.

2, Formula for theoretical weight of Square bar: a(length of a side) * a * 0.00785

3, The numbers with *mean that they are not regular or we don’t offer them.

-Regular length of Square Bar:

Steel | Length of a side (mm) | Length of steel (m) |

Normal steel | < 25 | 4~10 |

> 25 | 3~9 | |

Steel of high quality | All measure | 2~6 |

Tool steel >75 | 1~6 |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q5: Can stainless steel rust?

A5: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

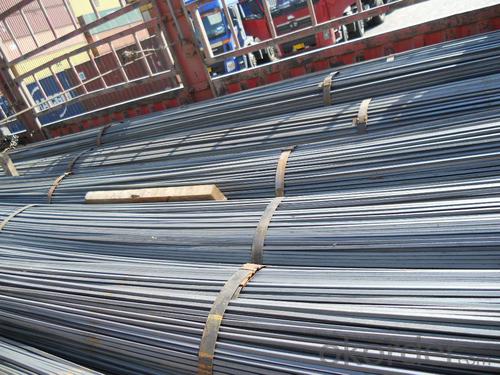

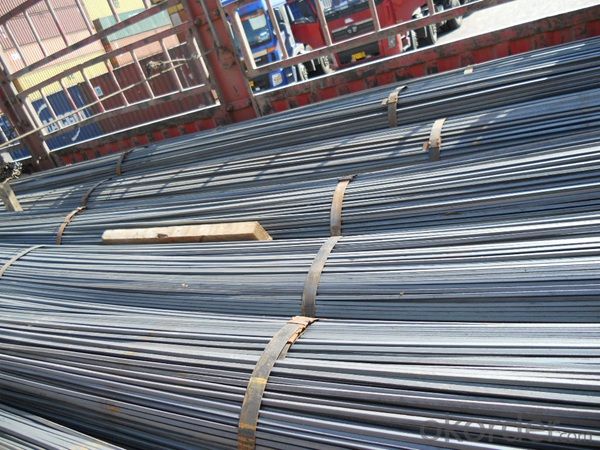

Images:

- Q: How do you use a steel square to create compound miter cuts?

- In order to create compound miter cuts using a steel square, a series of steps must be followed. To begin, the desired angle of the compound miter cut must be determined. This can be accomplished by either referring to project plans or using a protractor to measure the angle. Following this, position the steel square onto the workpiece at the chosen angle, ensuring that the long side of the square aligns with the edge of the workpiece. Once the square is properly placed, utilize a pencil or marker to mark the cut line along the edge of the square. This marking will indicate where the cut needs to be made. Next, the bevel angle of the miter saw or table saw must be adjusted to match the angle of the compound miter cut. This adjustment is typically made by loosening a bevel lock or manipulating a bevel gauge on the saw. After the bevel angle has been adjusted, align the marked cut line on the workpiece with the saw blade. It is important to double-check that the bevel angle matches the angle on the steel square. Lastly, proceed to make the compound miter cut with caution. Slowly push the workpiece through the saw, ensuring a clean and precise cut. Always prioritize safety when operating power tools and handling sharp blades. Wear appropriate protective gear and adhere to the manufacturer's instructions for your specific saw model.

- Q: What are the different types of steel squares used in metalworking?

- In metalworking, steel squares are essential tools used for measuring, marking, and checking right angles in various applications. There are several types of steel squares commonly used in metalworking, each with its own specific features and advantages. 1. Engineer's Square: This type of square is the most commonly used in metalworking. It typically has a blade that is longer than its beam, allowing for easier measurement of larger workpieces. Engineer's squares are known for their accuracy and are ideal for general layout work. 2. Machinist's Square: Machinist's squares are precision tools used for extremely accurate measurements. They have a hardened blade and a heavier construction than engineer's squares, providing improved stability and accuracy. Machinist's squares are commonly used for setup and alignment tasks. 3. Combination Square: Combination squares are versatile tools that combine a square, level, and protractor in one device. They usually consist of a steel rule with a sliding head that can be locked at different angles. Combination squares are useful for measuring, marking, and checking angles, as well as for setting depths and heights. 4. Try Square: Try squares, also known as tri-squares, have a shorter blade and beam than engineer's squares. They are primarily used for checking and marking right angles on smaller workpieces, such as woodworking projects. Try squares are lightweight and easy to handle. 5. Miter Square: Miter squares are specialized squares used for accurately marking and cutting angles for miter joints. They have adjustable blades that can be set at different angles. Miter squares are commonly used in woodworking and carpentry, but they can also be useful in metalworking when precise angled cuts are required. These are just a few examples of the different types of steel squares used in metalworking. Each square serves a specific purpose, providing metalworkers with the necessary tools to ensure accurate measurements, precise marking, and the creation of well-aligned structures.

- Q: Are steel squares resistant to rust and corrosion?

- Steel squares, in general, have the ability to resist rust and corrosion. They are typically manufactured using stainless steel, which contains a significant amount of chromium. This element plays a crucial role in providing stainless steel with its corrosion-resistant properties. By forming a protective layer, known as a passive film, chromium prevents oxygen from reaching the underlying metal, thus hindering the formation of rust. Nevertheless, it is worth noting that the degree of resistance to rust and corrosion may vary based on the quality of the steel employed. Stainless steel squares of higher quality will exhibit greater resistance to rust and corrosion compared to those of lower quality. Furthermore, the maintenance and care dedicated to the steel squares can also impact their resistance. Consistent cleaning and proper storage practices contribute to prolonging their lifespan and preserving their resistance to rust and corrosion.

- Q: How is a steel square used in construction?

- A steel square, also known as a framing square or a carpenter's square, is a versatile and essential tool used in construction. It is primarily used for measuring and marking right angles, ensuring precise angles and perpendicular lines during construction projects. One common application of a steel square is in framing walls. Carpenters use it to ensure that the studs are positioned at right angles, which is crucial for the stability and strength of the structure. By placing the square against the stud and the top or bottom plate, they can easily mark the correct position for each stud. Additionally, a steel square is used to determine and mark different angles. It has various markings and scales on its blade, allowing carpenters to measure and mark angles such as 45 degrees and 30 degrees accurately. This is particularly useful when constructing roofs, staircases, and other elements that require specific angles. Furthermore, a steel square can be used as a guide for cutting and marking materials. Carpenters often use it to mark straight lines on wood, ensuring precise and straight cuts. It can also be used to check the alignment of doors, windows, and other components during installation. In summary, a steel square is an indispensable tool in construction due to its versatility in measuring, marking right angles, determining angles, and guiding cuts. It helps carpenters and other construction workers ensure accuracy and precision in their projects, resulting in sturdy and well-built structures.

- Q: Can a steel square be used for checking the squareness of a wall frame?

- Yes, a steel square can be used for checking the squareness of a wall frame.

- Q: How do you use a steel square to mark a line parallel to an edge?

- To mark a line parallel to an edge using a steel square, follow these instructions: 1. Position the steel square on the surface, making sure that one side is touching the edge you want to mark parallel to. 2. Verify that the square is properly aligned and flush against the edge. 3. Securely hold the square in place to prevent any movement. 4. Employ a pencil or a scribe to trace a line alongside the edge of the steel square. 5. Continue marking the line until you reach your desired length. Remember to periodically check the square to guarantee it hasn't shifted while marking the line. Additionally, it is advised to use a sharp pencil or scribe for precise markings.

- Q: Can a steel square be used for checking the levelness of a wall stud?

- Checking the levelness of a wall stud cannot be done with a steel square. The steel square, or framing square, is mainly used for measuring and marking angles in carpentry and woodworking. It consists of a long arm and a shorter square arm at a 90-degree angle. To accurately check the levelness of a wall stud, the appropriate tool to use is a level. A level is a rectangular device with a straight edge and a bubble vial filled with liquid. When the bubble is centered between the lines in the vial, it indicates that the surface is level. Using a steel square for this purpose would yield inaccurate results. It is best to utilize a level, as it is specifically designed for this task and provides more precise measurements.

- Q: Can a steel square be used for drywall patching?

- Yes, a steel square can be used for drywall patching. It can be used to measure and mark the dimensions of the patch accurately, ensuring a precise fit. Additionally, the straight edge of a steel square can be used as a guide for cutting the drywall patch.

- Q: Can a steel square be used for checking the squareness of a deck frame?

- Indeed, the squareness of a deck frame can be assessed using a steel square. A steel square, which is also known as a framing square or carpenter's square, is a versatile tool commonly employed in the fields of carpentry and construction. It is comprised of two arms that intersect at a right angle, one of which is longer than the other. To evaluate the squareness of a deck frame utilizing a steel square, adhere to the subsequent steps: 1. Position the longer arm of the steel square against the edge of the deck frame, ensuring it is flush. 2. Extend the shorter arm of the steel square along the adjacent edge of the frame. 3. Observe for any gaps or incongruities between the frame and the steel square. If the frame is perfectly square, the steel square should align flawlessly with the edges of the frame. 4. In the event of gaps or misalignments, rectify the frame by gently tapping or pushing it until it achieves squareness. 5. Repeat this procedure for all corners of the deck frame to guarantee overall squareness. Employing a steel square is an efficient and dependable approach to ascertain the squareness of a deck frame. It furnishes a visual reference to ensure the frame maintains squareness, which is imperative for proper installation and structural soundness.

- Q: How do you use a steel square to create compound miter cuts?

- In order to create compound miter cuts using a steel square, a series of steps must be followed. To begin, the desired angle of the compound miter cut must be determined. This can be accomplished by either referring to project plans or using a protractor to measure the angle. Following this, position the steel square onto the workpiece at the chosen angle, ensuring that the long side of the square aligns with the edge of the workpiece. Once the square is properly placed, utilize a pencil or marker to mark the cut line along the edge of the square. This marking will indicate where the cut needs to be made. Next, the bevel angle of the miter saw or table saw must be adjusted to match the angle of the compound miter cut. This adjustment is typically made by loosening a bevel lock or manipulating a bevel gauge on the saw. After the bevel angle has been adjusted, align the marked cut line on the workpiece with the saw blade. It is important to double-check that the bevel angle matches the angle on the steel square. Lastly, proceed to make the compound miter cut with caution. Slowly push the workpiece through the saw, ensuring a clean and precise cut. Always prioritize safety when operating power tools and handling sharp blades. Wear appropriate protective gear and adhere to the manufacturer's instructions for your specific saw model.

Send your message to us

Hot Rolled Steel Square Bars Q235,A36,S235JR, SS400

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords