Heavy Duty Woven Geotextile Fabric Specifications for Needle Punched Nonwoven Geotextile in Highway Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 1500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Application of Needle Punched Nonwoven Geotextile for Highway Construction:

1. Water conservancy projec: seawall, dike,river canal engineering;Reservoir reinforcement engineering; Reclamation engineering; Flood control engineering.

2.Highway,railway and airport project: soft foundation reinforcement; Slope protection; Pavement structure layer reflective crack prevention; Drainage system; Greening belt.

3.Electrical engineering : Nuclear infrastructure;Thermal power ash dam project;Hydropower project.

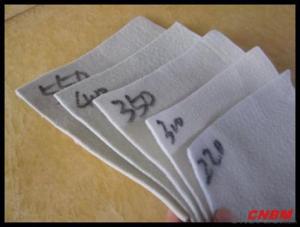

Technical Data Sheet of Needle Punched Nonwoven Geotextile for Highway Construction:

Index Spec.

Article | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 800 | |

1 | Quality error in unit area,% | -6 | -6 | -6 | -5 | -5 | -5 | -5 | -5 | -4 | -4 | -4 |

2 | Thickness,mm≥ | 0.8 | 1.2 | 1.6 | 1.9 | 2.2 | 2.5 | 2.8 | 3.1 | 3.4 | 4.2 | 5.5 |

3 | Width error,% | -0.5 | ||||||||||

4 | Breaking strength,KN/m≥ | 4.5 | 7.5 | 10.0 | 12.5 | 15.0 | 17.5 | 20.5 | 22.5 | 25.0 | 30.0 | 40 |

5 | Elongation at break,% | 40~80 | ||||||||||

6 | CBR puncture strength,KN≥ | 0.8 | 1.4 | 1.8 | 2.2 | 2.6 | 3.0 | 3.5 | 4.0 | 4.7 | 5.5 | 7.0 |

7 | Effective aperture 090(095),mm | 0.07~0.2 | ||||||||||

8 | Vertical permeability coefficient , cm/s | K X (10-4-10-3) K=1.0~9.9(K=1.0~9.9) | ||||||||||

9 | Tearing strength,KN≥ | 0.14 | 0.21 | 0.28 | 0.35 | 0.42 | 0.49 | 0.56 | 0.63 | 0.70 | 0.82 | 1.1 |

FAQ:

What is the main application of Needle Punched Nonwoven Geotextile for Highway Construction?

The main application of our Needle Punched Nonwoven Geotextile for Highway Construction is as follows: The highway, railway, soil-stone dam, breakwater, airport, backfill soil of retaining wall, slope protection, etc.

Where is your main market?

Our main market is in Middle East, South America and some African countries.

What is your advantages for Needle Punched Nonwoven Geotextile for Highway Construction?

One of the largest manufacturer of Needle Punched Nonwoven Geotextile for Highway Construction with advanced equipment, big production capacity and excellent quality.

Over the past decade a greater emphasis has been placed on the development and manufacturing of geosynthetic textiles. While the geosynthetics industry is comparatively new, it has already created products with applications in a wide range of industries including geotechnical, transportation, hydraulic, embankment management, and mining. In many cases, a single geosynthetic textile can solve or improve multiple civil engineering problems simultaneously.

The first example of a geosynthetic textile application is the use of a prefabricated pocket style vertical drain made from a nonwoven filter jacket specialized as a PVD filter material. The purpose of this product was to reduce the time needed for construction by quickly discharging water in the ground which speeds up the soil consolidation process. Overall, it proved to reduce construction time and speed up the consolidation of soft ground in a variety of different situations including road construction, the development of building sites, construction of gas and oil storage facilities, and bank revetment.

The second example of how geosynthetic textiles can provide solutions to civil engineering problems is the polyester woven geotextile mat. It is created from a high tenacity polyester filament which is highly dense. This particular geosynthetic textile has been used to reinforce soft ground and embankments, separate layers of sand and soft ground, prevent the uneven settlement of soft ground, and securing a safe path of travel for heavy equipment across soft ground.

The third example is a silt curtain or fence created by geosynthetic textiles. A silt curtain is installed in the water to prevent the spread of environmentally dangerous contaminants. These contaminants often result from coastal and Riverside construction projects although it can also be used in the event of an open water spill or leak. It has been shown effective at preventing the spread of fine soil and sand induced by construction. It can also prevent the contamination of the nearby seaports and help preserve sea farming and area beaches.

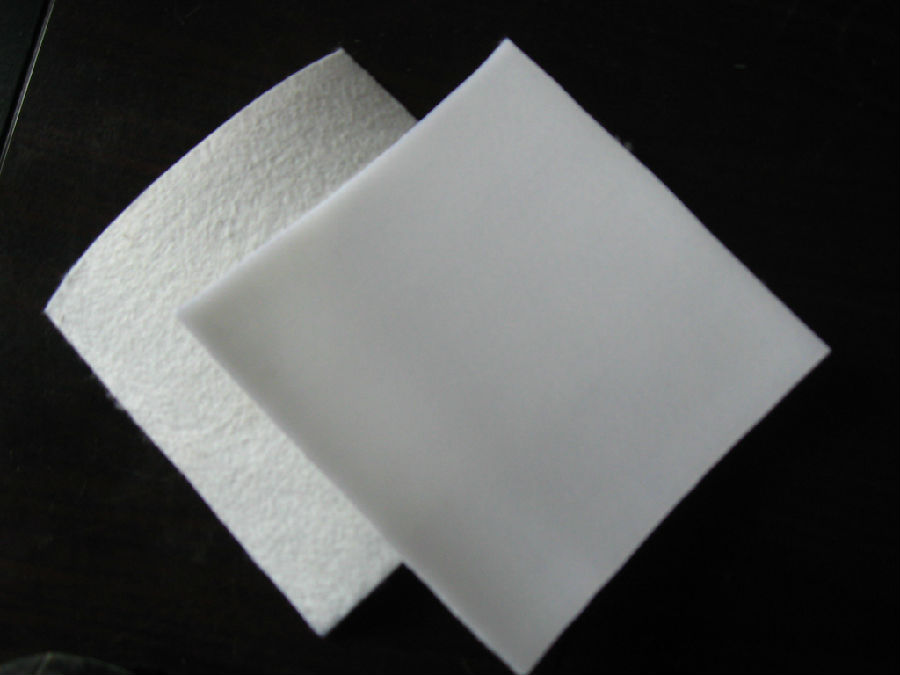

The fourth and final example of geosynthetic textiles assisting with civil engineering problems is the polyester needle punched nonwoven geotextile. It is typically made of continuous filament fiber to promote fast drainage and filtration. It has been used to help prevent landslides, control erosion on banks, protect waterproof layers in landfills, prevent road tracking, and protect waterproof sheets and tunnels.

There is no doubt geosynthetic textiles will continue to play a greater role in finding workable solutions to civil engineering problems across the globe. As their production continues to scale, prices will decrease which will lead to an increase in availability as well as further research and development.

- Q: Are geotextiles suitable for use in erosion control blankets?

- Yes, geotextiles are suitable for use in erosion control blankets. They are designed to provide soil stabilization, prevent erosion, and promote vegetation growth. Geotextiles offer effective erosion control by preventing soil movement while still allowing water infiltration.

- Q: Is the current tunnel construction, modular waterproof board (geotextile) is available?

- We use the soil is a geotech cloth waterproof board

- Q: Can geotextiles be used in foundation drainage systems?

- Yes, geotextiles can be used in foundation drainage systems. Geotextiles are commonly used as a filter and separator in drainage systems to prevent soil migration and clogging of drainage pipes. They help to improve the efficiency and longevity of foundation drainage systems by allowing water to flow freely while keeping the soil particles in place.

- Q: Are geotextiles commonly used in agriculture?

- Yes, geotextiles are commonly used in agriculture. Geotextiles have multiple applications in the agricultural industry, including soil stabilization, erosion control, weed suppression, and drainage management. They help improve soil quality, reduce erosion, and enhance crop growth, making them a valuable tool for many farmers and agricultural practices.

- Q: How do geotextiles help with reinforcement of geosynthetic tubes?

- Geotextiles help with the reinforcement of geosynthetic tubes by providing additional strength and stability to the structure. They act as a barrier between the soil and the tube, preventing soil intrusion and enhancing the tube's durability. Geotextiles also distribute the load more evenly, reducing the stress on the tube and preventing deformation or failure.

- Q: What are the materials used for spinning geotextiles?

- Geotextile is divided into several, filament spunbond acupuncture non-woven geotextile, this is the name suggests is to use silk to do; staple acupuncture non-woven geotextile, this is the use of fiber to do;

- Q: Geotextile and blind tube is how the drainage ah?

- Geotextile from the role of filtration, over the water, but soil, geotextile wrapped around the blind ditch like, I am specializing in the production of geotextiles, geomembrane and other materials, wish smooth.

- Q: What are the factors to consider when selecting geotextiles for a specific project?

- When selecting geotextiles for a specific project, there are several factors to consider. These include the project requirements and objectives, the type and intensity of loads the geotextiles will be subjected to, the site conditions and soil characteristics, the desired lifespan of the geotextiles, and the environmental considerations. Additionally, factors such as the cost, availability, and compatibility with other materials should also be taken into account.

- Q: Composite waterproof board, is the waterproof board and geotextile stick together call it?

- Yes. Now there are mainly adhesive technology, thermal composite process, Laminating process.

Send your message to us

Heavy Duty Woven Geotextile Fabric Specifications for Needle Punched Nonwoven Geotextile in Highway Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 1500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords