Special Steel S45C Cold Drawn Steel Round Bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product information

MAIN SPECIFIATION | ||

PRODUCTS | SIZE | USAGE |

Hot Rolled Round Bar | SIZE :Φ16-Φ150mm | BAR |

WEIGTH:1.0-5.0t | FLANGE | |

LENGTH:6-12m | EQUIPMENT MANUFACTUR | |

Forged Steel Bar | SIZE:Φ150-Φ300mm | BAR |

FLANGE | ||

WIRE | SIZE:Φ5.5-Φ18mm WEIGHT:1-2t | STANDARD |

THREADLET | ||

WIRE ROD | ||

Continuously Cast Bloom | Section:150²-220x260mm Φ180-Φ240mm | Hot Rolled Bar,Wire,Shapes |

LENGTH:6-9m | PIPE | |

STEEL BAR | SIZE:12"-25" | FORGED |

1.Grade:Austenitic Stainless steel 301,304,304cu, 301L,304N,310S,316,316L,316Ti,316N,317,317L,321,347,347H

Alloy steel : scm415,scm 420H ,scm435 ,s45c ,15Mrco ...

2.Standard: AISI, ASTM, DIN, GB, JIS

3.Shape:Round.

4.Diameter:10-415 mm.

5.Length:3---12 m.

6.Surface:Bright(cold drawn,smooth turned) or Black(Hot rolled, hot forged)

7.Procedure:rew elements(C,Fe,Ni,Mn,Cr,Cu.)---Smelted ingots by AOD finery---hot rolled into black suface---pickling in acid liquid---cold drawn----polished by automatically machine---cutting into pieces---checking quanlity---package.

8.Application:Architecture,Food,Chemical,shipping industry.

9.Certifacate:ISO 9001:2008, TUV Rheinland, Bureau Veritas.

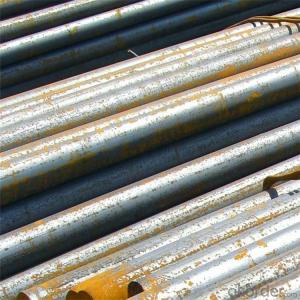

Product show

Workshop show

Shipping

1. FedEx/DHL/UPS/TNT for samples, Door-to-Door;

2. By Air or by Sea for batch goods, for FCL; Airport/ Port receiving;

3. Customers specifying freight forwarders or negotiable shipping methods!

Delivery Time: 3-7 days for samples; 5-25 days for batch goods.

Payment Terms

1.Payment: T/T, L/C, Western Union, MoneyGram,PayPal; 30% deposits; 70% balance before delivery.

2.MOQ: 1pcs

3.Warranty : 3 years

4.Package Informations: 1) EXPORT, In 20 feet (GW 25 ton) or 40 feet Container (GW 25 ton)

2)as customer's requirement

Why choose us?

(1) The leading exporter in China special steel industry.

(2) Large stocks for various sizes, fast delivery date.

(3) Good business relationship with China famous factories.

(4) More than 7 years steel exporting experience.

(5) Good after-sales service guarantee.

- Q: What are the different types of electrical steel?

- There are primarily two types of electrical steel: grain-oriented electrical steel (GOES) and non-grain-oriented electrical steel (NGOES). GOES is specifically designed to have superior magnetic properties in a specific direction, making it ideal for power transformers and other high-efficiency electrical devices. On the other hand, NGOES does not have a preferred magnetic direction and is commonly used in motors, generators, and other general-purpose electrical equipment.

- Q: What are the properties of alloy steel?

- Alloy steel is a type of steel that is made by combining iron with other elements, such as carbon, manganese, nickel, or chromium. It possesses unique properties that make it highly desirable for various applications. Some of the properties of alloy steel include high strength, excellent toughness, good corrosion resistance, and enhanced wear resistance. Additionally, alloy steel can be easily machined and welded, allowing for greater flexibility in its usage. The specific properties of alloy steel can vary depending on the particular elements added to it, leading to a wide range of alloys with different characteristics.

- Q: Can special steel be used in the pharmaceutical manufacturing equipment manufacturing industry?

- Yes, special steel can be used in the pharmaceutical manufacturing equipment manufacturing industry. Special steel alloys such as stainless steel are commonly used due to their corrosion resistance, durability, and ability to withstand high temperatures and harsh chemicals. These qualities make special steel a suitable choice for various equipment used in pharmaceutical manufacturing, including tanks, reactors, mixers, and piping systems.

- Q: How does special steel contribute to improving product lifespan?

- Special steel contributes to improving product lifespan in several ways. Firstly, it offers enhanced durability and strength, allowing products to withstand heavy usage, high temperatures, and harsh environments without succumbing to wear and tear. This increased resilience helps prevent premature failure and extends the lifespan of the product. Additionally, special steel often possesses excellent corrosion resistance properties, protecting the product from rust and degradation caused by exposure to moisture or chemicals. Moreover, special steel's superior machinability and formability enable the production of complex and precise components, reducing the risk of structural flaws or defects that could compromise the product's lifespan. Overall, the use of special steel in manufacturing contributes significantly to producing long-lasting, reliable, and high-quality products.

- Q: Can special steel be used in the renewable energy industry?

- Yes, special steel can be used in the renewable energy industry. Special steel offers high strength, corrosion resistance, and durability, making it suitable for various applications in renewable energy, such as wind turbines, solar panels, and hydroelectric power systems. It can withstand harsh environmental conditions and provide structural stability, contributing to the efficiency and longevity of renewable energy equipment.

- Q: What are the main characteristics of alloy steel?

- Alloy steel, which is produced by incorporating specific elements like chromium, nickel, or molybdenum into iron, possesses distinct properties and qualities. Some key features of alloy steel are as follows: 1. Remarkable strength: Alloy steel is renowned for its exceptional strength. The introduction of alloying elements enhances its capacity to endure high pressures and heavy loads, making it an ideal choice for applications necessitating a robust and long-lasting material. 2. Enhanced hardness: Alloy steel is also recognized for its hardness, surpassing that of regular carbon steel. This attribute renders it resistant to wear, abrasion, and deformation, making it suitable for applications that require resistance to impact or wear, such as the production of cutting tools or machinery components. 3. Resistance to corrosion: Depending on the specific alloying elements employed, alloy steel can display excellent resistance to corrosion. For instance, the addition of chromium is a common practice to create stainless steel, which exhibits high resistance to rust and corrosion. This attribute positions alloy steel as a preferred material in industries where exposure to moisture or corrosive environments is prevalent. 4. Heat endurance: Alloy steel possesses the ability to withstand high temperatures without compromising its strength or structural integrity. The inclusion of elements like nickel, molybdenum, or vanadium augments its resistance to thermal expansion, oxidation, and softening at elevated temperatures. This quality renders alloy steel suitable for applications in the aerospace, automotive, and power generation sectors. 5. Versatility: Alloy steel is a versatile material that can be readily tailored to meet specific requirements. Manufacturers can create alloy steel with a broad range of properties, such as improved ductility, toughness, or electrical conductivity, by modifying the composition and proportions of alloying elements. This adaptability permits the utilization of alloy steel in diverse industries, encompassing construction, manufacturing, and engineering. In conclusion, alloy steel exhibits high strength, hardness, corrosion resistance, heat endurance, and versatility. These characteristics establish alloy steel as the preferred choice for a wide array of applications that demand a sturdy, durable, and dependable material.

- Q: How does special steel contribute to reducing product failure?

- Special steel contributes to reducing product failure by providing enhanced mechanical properties and superior resistance to wear, corrosion, and fatigue. Its exceptional strength, toughness, and durability allow for the production of components that can withstand high stress, extreme temperatures, and harsh environments, minimizing the risk of failure. Additionally, special steel's precise composition and controlled manufacturing processes ensure consistent quality and reliability, reducing the likelihood of defects or weaknesses that could lead to product failure.

- Q: How does special steel perform at high temperatures?

- Special steel performs well at high temperatures due to its unique composition and properties. It exhibits excellent strength, corrosion resistance, and thermal stability, enabling it to retain its mechanical properties even at elevated temperatures. Additionally, special steel has low thermal expansion, ensuring dimensional stability even under extreme heat. These characteristics make it ideal for applications in industries such as aerospace, oil and gas, and power generation, where high temperatures are commonplace.

- Q: Can special steel be used in the cement manufacturing industry?

- Yes, special steel can be used in the cement manufacturing industry. Special steel is often used for various applications in the cement industry, such as in the construction of kilns, crushers, mills, and other heavy-duty equipment. Its high strength, corrosion resistance, and durability make it suitable for withstanding the harsh conditions and abrasive materials involved in cement production.

- Q: What are the different impact-resistant grades of special steel?

- Steel alloys known as impact-resistant grades are designed to withstand high impact and shock loads without fracturing or deforming. These grades of steel are crucial in industries like construction, mining, automotive, and defense, where resistance to impact and toughness are essential. Numerous impact-resistant grades of special steel are available, each with its own unique characteristics and properties. Some commonly used grades include: 1. AR400: This steel has a hardness of 400 Brinell (HB) and is highly resistant to abrasion and impact. It finds applications in bucket liners, crushers, and hoppers where wear resistance is critical. 2. AR500: With a hardness of 500 HB, AR500 steel offers even greater resistance to wear and impact compared to AR400. It is frequently used in heavy machinery, mining equipment, and armored vehicles. 3. AR600: This steel boasts a hardness of 600 HB, making it one of the toughest and most impact-resistant options. It is ideal for applications that require extreme wear resistance and durability, such as chutes, conveyors, and ballistic protection. 4. T-1: T-1 steel is a high-strength, low-alloy (HSLA) steel that delivers excellent impact resistance and toughness. It is commonly utilized in structural components, heavy equipment, and offshore drilling rigs, where high strength and toughness are essential. 5. QT or Quenched and Tempered Steels: These steels undergo specific heat treatment to enhance their toughness and impact resistance. They are popular in applications that demand high strength, toughness, and impact resistance, such as gears, shafts, and armor plates. It is important to note that the impact resistance of a specific steel grade depends not only on its composition but also on factors like heat treatment, fabrication techniques, and design considerations. Therefore, consulting steel manufacturers or experts is crucial in determining the most suitable impact-resistant grade for a particular application.

Send your message to us

Special Steel S45C Cold Drawn Steel Round Bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords