S45C Grade Steel Round Bar for Machine Structural Use

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

S45C Grade Steel Round Bar for Machine Structural Use

Product Description of S45C Grade Steel Round Bar for Machine Structural Use

1. Steel grade: SAE1045, 45#, C45, S45C

2. Length: 6M-12M

3. Diameter: 16mm-300mm

4. Product range: round bar, flat bar, square bar

5. Technique: Hot rolled, forged, cold drawn

Specification of S45C Grade Steel Round Bar for Machine Structural Use

Material | S45C | 16-300mm | ||

Process | EAF + LF + VD + Forged + Heat Treatment (optional) | Length (mm) | Max 12m | |

Heat treatment | Normalized / Annealed / Quenched / tempered | Flat bar | Thickness(mm) | 8-500mm |

Delivery condition | Hot forged +Rough machined (black surface after Q/T)+ Turned (optional) | Width(mm) | 70-200mm | |

Test | Ultrasonic test according to SEP 1921-84 D/d | Length (mm) | Max 12m |

Chemical Composition of S45C Grade Steel Round Bar for Machine Structural Use

C | Si | Mn | Cr | Ni | Cu |

0.40~0.49 | 0.17~0.37 | 0.35~0.65 | ≤0.25 | ≤0.30 | ≤0.25 |

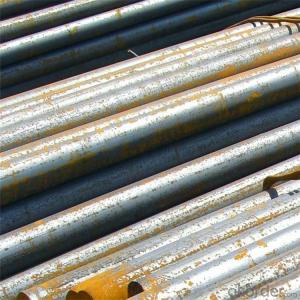

Photo Show of S45C Grade Steel Round Bar for Machine Structural Use

Packing and Delivery:

Packing in bundle package, or as customer's requirements.

Delivery Detail: 45 days after receiving the deposit.

Usage and Applications of S45C Grade Steel Round Bar for Machine Structural Use

1. Steel round bar is used in a large number of architectural and engineering structures. Or it can be used in construction of plants for the production of steel house frames, high-voltage transmission towers, bridges, vehicles, boilers, containers, ships, etc.

2. And we can use this kind of product on the performance of the mechanical parts if the demand is not very high.

3. Some special material steel round bar can be used for main shaft of steamer, hummer shank, with big section and supper force.

Company Information

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

F A Q

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

- Q: Can steel round bars be used in the aerospace manufacturing industry?

- Yes, steel round bars can be used in the aerospace manufacturing industry. Steel is a commonly used material in aerospace applications due to its strength, durability, and resistance to high temperatures. Steel round bars are often used in the construction of aircraft frames, landing gears, and engine components.

- Q: Are steel round bars prone to deformation?

- When steel round bars are manufactured and used correctly, they usually do not deform. Steel is recognized for its strong tensile strength and durability, which means it can resist bending or warping in normal situations. However, it is essential to remember that excessive force or mishandling can still lead to deformation in steel round bars. Overloading, improper storage, or using inappropriate machining techniques can all contribute to the bars bending or twisting. Hence, it is vital to adhere to recommended guidelines and industry standards to guarantee the durability and longevity of steel round bars.

- Q: What is the minimum yield strength of steel round bars?

- The minimum yield strength of steel round bars can vary depending on the specific grade and type of steel being used. However, in general, most steel round bars have a minimum yield strength of 36,000 psi (pounds per square inch) or 250 megapascals (MPa). This minimum yield strength is typically required to ensure that the steel round bars have sufficient strength and durability to withstand applied loads and prevent deformation or failure. It is important to note that different applications may require steel round bars with higher yield strengths to meet specific performance requirements.

- Q: Can steel round bars be used for construction purposes?

- Indeed, construction purposes can make use of steel round bars. Several applications in construction commonly utilize steel round bars, including reinforcement in concrete structures, support for beams and columns, and as structural components in bridges, buildings, and infrastructure projects. The exceptional tensile strength and durability of steel render it a perfect option for construction purposes, capable of withstanding heavy loads, providing stability, and ensuring the longevity and safety of structures. Furthermore, steel round bars offer versatility, as they can be easily fabricated and customized to meet specific project requirements. Hence, due to their excellent mechanical properties, reliability, and cost-effectiveness, steel round bars find extensive use in the construction industry.

- Q: What are the advantages of using aluminum-magnesium alloy steel round bars?

- There are several advantages of using aluminum-magnesium alloy steel round bars. Firstly, these bars have a high strength-to-weight ratio, making them lightweight yet sturdy, ideal for applications where weight reduction is crucial. Secondly, the alloy's corrosion resistance properties make it suitable for various environments, including marine and industrial settings. Additionally, aluminum-magnesium alloy steel round bars offer excellent thermal conductivity, allowing for efficient heat dissipation. Lastly, these bars can be easily machined, welded, and formed, providing flexibility during fabrication and reducing manufacturing costs.

- Q: What is the maximum temperature steel round bars can withstand?

- The maximum temperature that steel round bars can withstand depends on the specific grade and composition of the steel. However, most standard carbon steels can typically withstand temperatures up to approximately 1000°C (1832°F) before their mechanical properties begin to significantly degrade.

- Q: Are steel round bars suitable for use in the manufacturing of valves?

- Yes, steel round bars are suitable for use in the manufacturing of valves. Steel round bars offer excellent strength, durability, and corrosion resistance, making them ideal for various applications including valve production. Additionally, steel round bars can be easily machined and fabricated into different shapes and sizes, allowing for customization according to specific valve requirements.

- Q: What are the applications of steel round bars in the aerospace industry?

- Steel round bars are widely used in the aerospace industry due to their exceptional strength, durability, and versatility. These bars are utilized in various applications, including: 1. Structural Components: Steel round bars are commonly used in the production of structural components in the aerospace industry. They are used for manufacturing aircraft frames, landing gear, wing spars, and other critical structural elements. The high tensile strength of steel ensures the structural integrity and safety of the aircraft. 2. Fasteners: Steel round bars are also used to produce fasteners such as bolts, screws, and pins. These fasteners play a crucial role in holding different parts of the aircraft together. Steel's strength and resistance to fatigue make it an ideal material for these critical connections. 3. Engine Components: Steel round bars find application in the production of various engine components. They are used to manufacture shafts, crankshafts, connecting rods, and turbine blades. These components need to withstand high temperatures, pressure, and mechanical stress, and steel's heat resistance and strength make it suitable for these demanding conditions. 4. Landing Gear: The landing gear of an aircraft is subjected to immense stress during takeoff, landing, and taxiing. Steel round bars are used in the construction of landing gear components such as axles and struts. The high strength and toughness of steel ensure the landing gear's ability to withstand the forces encountered during landing operations. 5. Tooling and Fixtures: Steel round bars are used to manufacture tooling and fixtures necessary for the production and maintenance of aircraft. These tools and fixtures are employed in various processes, including machining, assembly, and inspection. Steel's hardness and machinability make it an ideal material for these applications. In summary, steel round bars have numerous applications in the aerospace industry, ranging from structural components to fasteners, engine parts, landing gear, and tooling. The unique combination of strength, durability, and versatility offered by steel makes it an essential material in ensuring the performance, safety, and reliability of aerospace systems.

- Q: Can steel round bars be used in the production of sporting goods?

- Sporting goods can indeed utilize steel round bars. Steel, a versatile material renowned for its strength and durability, proves fitting for a wide spectrum of applications within the sporting goods industry. To illustrate, steel round bars can be employed to fabricate various components, including shafts, handles, frames, and supports for sporting equipment such as golf clubs, hockey sticks, weightlifting bars, and exercise machines. The robust tensile strength of steel ensures that these components can withstand the rigorous forces and pressures exerted during sports activities, thus affording stability and longevity to the resultant products. Additionally, steel round bars can be effortlessly machined, welded, and molded into different shapes and sizes to meet the particular requirements of each sporting good. Furthermore, steel's ability to resist corrosion renders it an ideal choice for outdoor sporting equipment that is subjected to diverse weather conditions. In summary, steel round bars are an immensely popular option in the production of sporting goods owing to their strength, durability, versatility, and capacity to endure the demands of various sports.

- Q: What are the different types of steel round bar alloys for improved corrosion resistance?

- There are several types of steel round bar alloys that are known for their improved corrosion resistance. Some of the commonly used alloys include stainless steel, weathering steel, and duplex stainless steel. 1. Stainless Steel: This alloy contains a minimum of 10.5% chromium, which forms a thin, protective layer of chromium oxide on the surface of the steel. This layer acts as a barrier against corrosion, making stainless steel highly resistant to rust and other forms of corrosion. Different grades of stainless steel, such as 304 and 316, offer varying levels of corrosion resistance depending on the specific application. 2. Weathering Steel: Also known as Corten steel, weathering steel develops a protective rust-like appearance when exposed to the weather. This self-healing characteristic makes it resistant to atmospheric corrosion. The addition of copper, chromium, and nickel in weathering steel enhances its corrosion resistance and enables it to withstand harsh environmental conditions without the need for painting. 3. Duplex Stainless Steel: Duplex stainless steel is a combination of austenitic and ferritic stainless steels. This alloy offers excellent corrosion resistance due to its high chromium and molybdenum content. Duplex stainless steel is particularly resistant to localized corrosion, such as pitting and crevice corrosion, making it suitable for applications in aggressive environments like marine and chemical industries. It is important to note that the choice of steel round bar alloy for improved corrosion resistance depends on the specific application requirements and environmental conditions. Consulting with a materials engineer or corrosion specialist can help determine the most suitable alloy for a particular application.

Send your message to us

S45C Grade Steel Round Bar for Machine Structural Use

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords