Special Steel ASTM1020 Carbon Structural Steel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product information:

1.Chemical performance:

Model | C | Si | Mn | P | S |

GB45 | 0.42-0.50 | 0.17-0.37 | 0.50-0.80 | 0.030 | 0.030 |

2.Mechanical performance:

Strength of extension | 600MPA |

Yield point | 355MPA |

Elongation | 16% |

Contractibility rate | 40% |

Impacting energy | 39J |

3.Size tolerance:

Length tolerance | +100mm/-0mm |

diameter tolerance | +/-1.0mm |

Straightness | Max 6mm/m |

4.

specification | Outer Diameter:14mm-180mm |

Standard | GB,JIS,DIN,AISI,ASTM,ISO,NF |

Certificate | ISO9001-2008 |

Application | A) General service industries (petroleum, food, chemical, paper, fertilizer, Fabric, aviation and nuclear) B) Fluid, gas and oil transport C) Pressure and heat transmission D) Construction and ornament E) Boiler heat exchangers |

Test | flaw detection According to customers' requests |

Processing | Cold Drawn/Cold Rolled/Hot Rolled |

Packing | as your requirement |

trade term | FOB; CNF; CIF PORT: TIANJIN, China |

payment | T/T ,L/C,D/P |

delivery time | Within 15 DAYS |

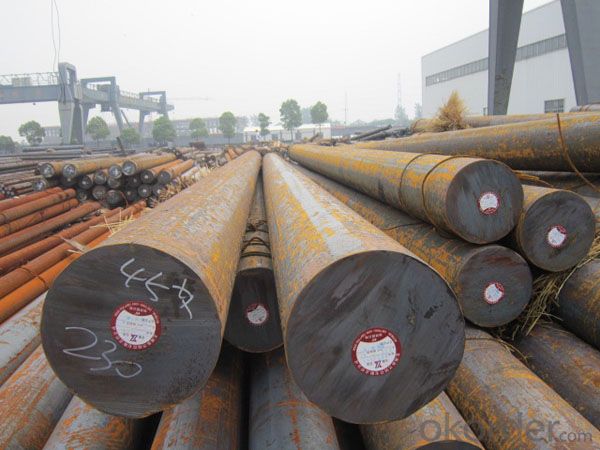

Product Show:

Workshop Show:

Shipping

1. FedEx/DHL/UPS/TNT for samples, Door-to-Door;

2. By Air or by Sea for batch goods, for FCL; Airport/ Port receiving;

3. Customers specifying freight forwarders or negotiable shipping methods!

Delivery Time: 3-7 days for samples; 5-25 days for batch goods.

Payment Terms

1.Payment: T/T, L/C, Western Union, MoneyGram,PayPal; 30% deposits; 70% balance before delivery.

2.MOQ: 1pcs

3.Warranty : 3 years

4.Package Informations: 1) EXPORT, In 20 feet (GW 25 ton) or 40 feet Container (GW 25 ton)

2)as customer's requirement

Why choose us?

(1) The leading exporter in China special steel industry.

(2) Large stocks for various sizes, fast delivery date.

(3) Good business relationship with China famous factories.

(4) More than 7 years steel exporting experience.

(5) Good after-sales service guarantee.

- Q: How is wear-resistant alloy steel used in the production of mining equipment?

- Wear-resistant alloy steel is extensively used in the production of mining equipment to enhance durability and strength. It is used to manufacture various components like buckets, blades, drill bits, and crusher liners that are subjected to abrasive materials and harsh mining conditions. The use of wear-resistant alloy steel ensures that these equipment parts can withstand the high impact and abrasion encountered during mining operations, thereby increasing their longevity and reducing maintenance costs.

- Q: What are the different types of electrical steel?

- There are primarily two types of electrical steel: grain-oriented electrical steel (GOES) and non-grain-oriented electrical steel (NGOES). GOES is specifically designed to have superior magnetic properties in a specific direction, making it ideal for power transformers and other high-efficiency electrical devices. On the other hand, NGOES does not have a preferred magnetic direction and is commonly used in motors, generators, and other general-purpose electrical equipment.

- Q: How does special steel contribute to the pharmaceutical industry?

- Special steel plays a crucial role in the pharmaceutical industry by offering exceptional strength, corrosion resistance, and durability. It is used in the manufacturing of various equipment and components such as storage tanks, reactors, piping systems, and precision instruments. The unique properties of special steel ensure the integrity and purity of pharmaceutical products, prevent contamination, and enable efficient and safe production processes.

- Q: What are the different types of special steel coatings?

- There are several different types of special steel coatings that are used to enhance the properties and performance of steel. Some of the most common types include: 1. Galvanized Coatings: This type of coating involves the application of a layer of zinc to the steel surface. Galvanized coatings provide excellent corrosion resistance, making them suitable for outdoor applications and structures exposed to harsh environments. 2. Epoxy Coatings: Epoxy coatings are known for their exceptional durability and chemical resistance. They are often used to protect steel from corrosion, abrasion, and chemical exposure. Epoxy coatings can be applied as single or multi-layer systems, enhancing the steel's lifespan and performance. 3. Powder Coatings: Powder coatings are a type of dry coating that is applied electrostatically and then cured under heat. They offer excellent protection against corrosion, impact, and UV damage. Powder coatings are available in a wide range of colors and finishes, making them a popular choice for aesthetic purposes as well. 4. Thermal Spray Coatings: These coatings involve the application of molten particles onto the steel surface using a thermal spray gun. The most common types of thermal spray coatings for steel are ceramic coatings, which provide enhanced wear resistance, thermal insulation, and corrosion protection. 5. PVD Coatings: Physical Vapor Deposition (PVD) coatings involve the deposition of thin layers of metallic or ceramic materials onto the steel surface through a vaporization process. PVD coatings provide improved hardness, wear resistance, and low friction properties to the steel. 6. Organic Coatings: Organic coatings, such as polyurethane or acrylic coatings, offer protection against corrosion, UV damage, and chemical exposure. These coatings are commonly used in architectural applications, automotive parts, and industrial equipment. 7. Chrome Plating: Chrome plating involves the deposition of a layer of chromium onto the steel surface. This coating provides excellent corrosion resistance, hardness, and a decorative finish. Chrome plating is often used in automotive applications and for decorative purposes. It is essential to select the appropriate type of special steel coating based on the specific requirements of the steel component or structure, including the level of corrosion resistance, durability, aesthetics, and environmental factors.

- Q: What are the advantages of using special steel in industrial applications?

- Using special steel in industrial applications has several advantages. Firstly, it offers exceptional strength and durability, making it suitable for heavy-duty tasks. The unique composition and manufacturing process of special steel result in a material that can withstand high levels of stress, extreme temperatures, and harsh environmental conditions. This makes it ideal for industries such as construction, automotive, and manufacturing, where reliable and long-lasting materials are required. Secondly, special steel exhibits excellent corrosion resistance. It can resist the damaging effects of moisture, chemicals, and other corrosive agents, which is crucial in industries like marine, oil and gas, and chemical processing. The corrosion resistance of special steel reduces the need for frequent maintenance and replacement, saving both time and costs for industrial applications. Furthermore, special steel offers superior machinability and formability. It can be easily shaped, cut, and welded to meet specific design requirements. This versatility allows for complex and intricate designs in various industrial applications, including machinery, tools, and equipment. Another advantage of special steel is its ability to maintain its properties at high temperatures. It has excellent heat resistance, ensuring that it remains strong and stable even under extreme heat conditions. This makes special steel suitable for applications involving high-temperature environments, such as aerospace, power generation, and furnace components. Additionally, special steel can exhibit excellent wear resistance and hardness. It can withstand abrasion, friction, and impact, making it ideal for applications where materials are subjected to heavy wear and tear, such as mining, construction equipment, and cutting tools. The wear resistance of special steel ensures that components have a longer lifespan and require less frequent replacement. In conclusion, the use of special steel in industrial applications brings forth exceptional strength and durability, corrosion resistance, machinability and formability, heat resistance, and wear resistance. These properties make special steel a preferred choice for a wide range of industries, contributing to improved performance, longevity, and cost-effectiveness.

- Q: How does special steel contribute to reducing product failure?

- Special steel contributes to reducing product failure by providing enhanced mechanical properties and superior resistance to wear, corrosion, and fatigue. Its exceptional strength, toughness, and durability allow for the production of components that can withstand high stress, extreme temperatures, and harsh environments, minimizing the risk of failure. Additionally, special steel's precise composition and controlled manufacturing processes ensure consistent quality and reliability, reducing the likelihood of defects or weaknesses that could lead to product failure.

- Q: How is special steel used in the textile industry?

- Special steel is used in the textile industry for various applications such as manufacturing textile machinery, fabricating cutting tools, and producing components for textile production processes. It provides the necessary strength, durability, and precision required to handle the high-speed and high-pressure operations involved in textile manufacturing.

- Q: How is special steel stored and transported?

- Special steel is typically stored and transported in a controlled environment to ensure its quality and prevent any damage or contamination. It is stored in covered warehouses or facilities equipped with proper ventilation, humidity control, and temperature regulation. Additionally, special steel is often stored on racks or shelves to prevent direct contact with the ground and minimize the risk of corrosion. When it comes to transportation, special steel is usually transported in specially designed containers or crates, ensuring protection from external elements and providing secure handling during transit.

- Q: What are the factors that affect the machinability of special steel?

- The factors that affect the machinability of special steel include its chemical composition, microstructure, hardness, and the presence of impurities or additives. Additionally, the cutting conditions and tool materials used during machining operations also play a significant role in determining the machinability of special steel.

- Q: Can special steel be used in the beverage manufacturing industry?

- Yes, special steel can be used in the beverage manufacturing industry. Special steel, such as stainless steel, is commonly used in beverage processing equipment due to its corrosion resistance, hygienic properties, and durability. It is particularly suitable for manufacturing tanks, pipes, valves, and other components that come into contact with beverages, ensuring a high level of safety and maintaining the quality of the products.

Send your message to us

Special Steel ASTM1020 Carbon Structural Steel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords