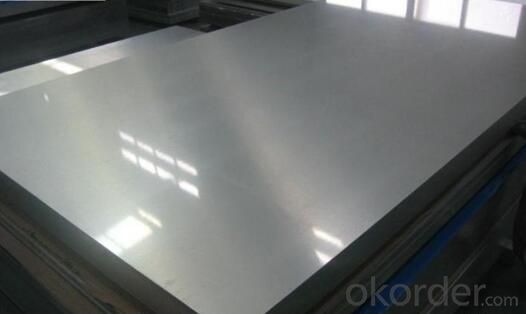

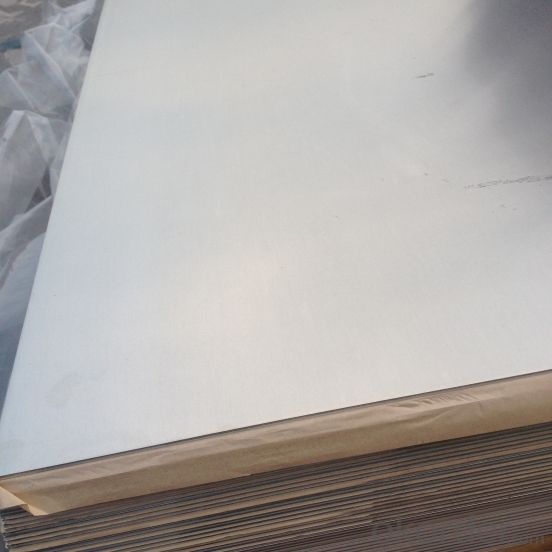

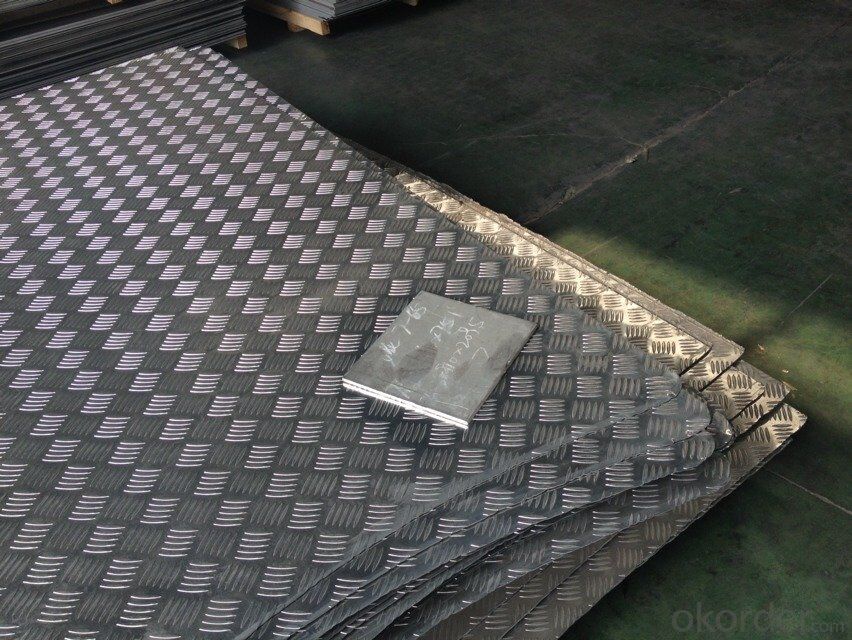

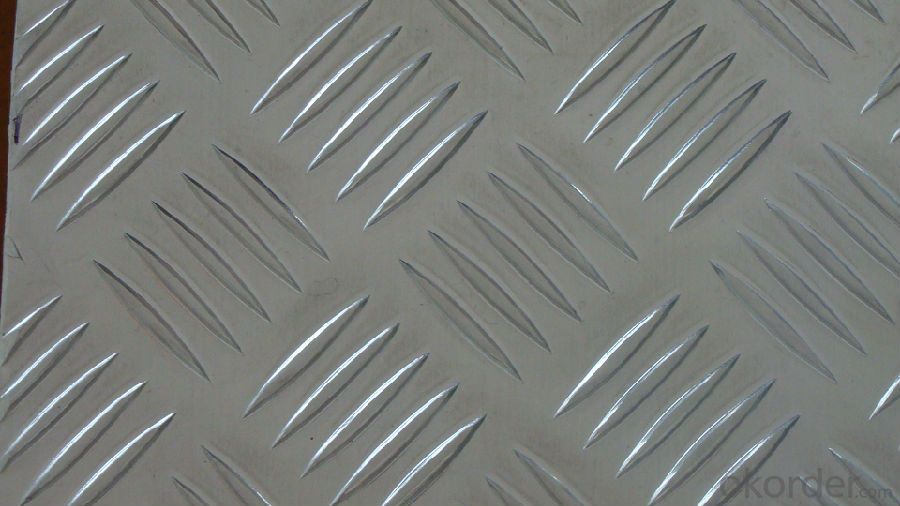

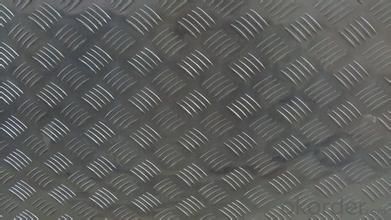

Aluminum Silicon Carbide Sheets - Special Alloy Extrusion Aluminum 1050 Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Aluminum Sheet for Making Aluminum Composite Panel

Aluminum sheet specifications:

1) Alloy : 1050 1060 1070 1100 2024 3003 3004 3105 3A21 5005 5052 5083 5754 5182 5454 5456 6061 6063 7075 8011 etc

2) Temper: O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc

3) Thickness: 0.1mm to 300mm

4) Width:20mm to 3300mm

5)Length: ≤ 12000mm

6) Protective film can be added

7) Production Line: DC and CC production line

Discription:

Width: 50-800mm

Thickness: 8-25mic

Length: 3-300m

Character:

High-temperature sterilization

Made of advanced food grade alu material,no pollution

Eco-friendly, recoverable and recyclable

Application:

widely used for food cooking, freezing wrapping, storing etc, the main application are for household and catering, which are targeting for retail market and food service market, such as hypermarket, chain store and hotel, restaurant etc.

Packing:

One roll in an individual box or printed PP bag

Certain quantities in a standard carton

Depends on customer’s request

Service

1. We have the good and professional team, have a good after-sales service.

2. Accept any drawings or your samples to develop new product.

3. Offer relateive technical support,quick response,all your inquire will replied within 24 hours.

4. OEM, buyer design, buyer label services provided.

5. Have the certification of ISO 9001, SGS.

6. Special discount and protection of sales area provided to our distributor.

FAQ

Q1:Do you provide sample? How many days will samples be finished?

Free samples will be provided if needed, but customers should undertake shipping cost or freight charges, samples will be finished in 5-7days

Q2: Can we visit your factory?

Welcome to our factory at any time.

Q3: Complaint solving process

Finding your salesman—Salesman provide you the solution (If it’s our responsibility, we will resend substitutes or return money or provide discount for your next order, etc.; If it’s shipping company’s responsibility, we will also help you until the problem is resolved.) —If salesman can’t solve your problem, please call our manager .

Q4: Delivery time

3~30working days after confirming the payment. If the order is urgent, we will push our workers to finish in advance.

Q5: What's your MOQ?

Normally 8MT are requested as the minium order quantity ,we shall give

additional instructions in special circumstances.

Q6: What are the terms of payment and currencies do you accept?

T/T or L/C is accepted, currently we appreciated your payment through

USD,EUR, RMB

Q7: Do you accept customized orders?

Yes, we do. Your customized orders are always welcomed. Please kindly offer us your samples or drawings, so that we can customize the products according to your preferences. About any further detail, please feel free to contact us.

Q8: What information should I let you know if I want to get a quotation?

Your detailed requirements regarding the products's dimensions, including shape, thickness, top out (length*width*height), and your order quantity are highly appreciated if you want further information about our quotation

Q9: How about the mass production?

The lead time of mass production depend on quantity, usually 25-30days (20FT) .

- Q: Can aluminum sheets be used for bus shelters?

- Yes, aluminum sheets can be used for bus shelters. Aluminum is a lightweight and durable material that can withstand harsh weather conditions, making it suitable for outdoor structures like bus shelters. Additionally, aluminum can be easily fabricated and customized to meet the specific design requirements of bus shelters.

- Q: Are aluminum sheets affected by UV radiation or sunlight exposure?

- Yes, aluminum sheets are affected by UV radiation and sunlight exposure. Over time, exposure to UV radiation and sunlight can cause the aluminum sheets to oxidize, resulting in a dull and discolored appearance. Additionally, prolonged exposure to UV rays can weaken the material, making it more prone to cracking or breaking. To protect aluminum sheets from the damaging effects of UV radiation, it is recommended to apply a protective coating or use anodized aluminum, which has a more robust and durable surface.

- Q: What are the common uses of aluminum sheets?

- Aluminum sheets are highly versatile and widely used in various industries due to their excellent properties. Some common uses of aluminum sheets include: 1. Construction: Aluminum sheets are commonly used in the construction industry for roofing, siding, and insulation purposes. They are lightweight, durable, and corrosion-resistant, making them ideal for creating a protective barrier against the elements. 2. Transportation: Aluminum sheets are extensively used in the automotive and aerospace industries. They are used in the manufacturing of car bodies, truck trailers, and aircraft parts due to their high strength-to-weight ratio. The lightweight nature of aluminum sheets helps improve fuel efficiency and reduce overall vehicle weight. 3. Packaging: Aluminum sheets are commonly used for packaging purposes. They are widely used in the food and beverage industry for making cans, foils, and containers. Aluminum sheets provide an effective barrier against moisture, light, and oxygen, ensuring the freshness and safety of the packaged products. 4. Electrical and Electronics: Aluminum sheets find applications in the electrical and electronics industry due to their excellent conductivity. They are used for manufacturing electrical enclosures, heat sinks, and wiring due to their ability to dissipate heat efficiently and protect sensitive electronic components. 5. Marine Industry: Aluminum sheets are highly valued in the marine industry due to their corrosion-resistant properties. They are used for constructing boat hulls, ship fittings, and other marine equipment. Aluminum sheets' ability to withstand harsh marine environments and their lightweight nature make them an attractive choice. 6. Decorative Applications: Aluminum sheets are commonly used in architectural applications for their aesthetic appeal. They can be easily shaped, formed, and colored to create various decorative elements such as wall cladding, ceilings, and decorative panels. Overall, the common uses of aluminum sheets span numerous industries, including construction, transportation, packaging, electrical and electronics, marine, and decorative applications, highlighting the versatility and importance of this material in various sectors.

- Q: This question asks if there are distinctions among various coatings applied to aluminum sheets.

- <p>Yes, there are significant differences between different types of coatings on aluminum sheets. These differences can include the purpose of the coating, such as for corrosion resistance, decorative effects, or enhanced durability. The materials used for the coatings can also vary, with options like anodizing, powder coating, or paint. Each type of coating has unique properties, such as resistance to weather, chemicals, or UV rays, and they can affect the surface appearance, weight, and cost of the aluminum sheet. The choice of coating often depends on the specific application and environmental conditions the aluminum sheet will be subjected to.</p>

- Q: I know aluminium forms a protective layer of aluminum oxide and hence water does not corrodes it easily.However, since the oxide is amphoteric, won't it react with acids and subsequently be dissolved?What is the main reason aluminium cans are used?

- Because of the aluminum chemical properties. Aluminum Oxide (Al2O3) is an extremely hard and compact material, so when the metal is exposed, it gets a very thin coat of Al2O3 that has a 9 hardness (only diamond is harder), that protects the rest of the metal from the atmosphere. Also, you should question if the phosphoric acid actually attacks aluminum, that is because that acid is found in Pepsi and coke..., BUT, as far as i know cans have a little plastic coat inside..., so the liquid does not get in touch with the aluminum.

- Q: has aluminum sheet reacted with concentrated sulfuric acid?

- it can be regarded as no reaction, concentrated sulfuric acid will make aluminum's surface inactivation,and produce a layer of dense aluminium oxide film which will prevent further reaction.

- Q: 4.0mm five bars, aluminum plate, 4 aluminum plate, one ton, how many square?

- The price is calculated according to the price of aluminum ingot + processing fees (aluminum state), the specific price according to the size of the aluminum plate, zero shear and the whole board price also has the difference, Jiangsu Yi Heng Liu Guangxi Henan Mingtai aluminum has the.The square and the thickness are multiplied, and then multiplied by the density is the weight, and then by weight conversion on it

- Q: Is it possible to purchase recycled aluminum sheets from a local supplier or manufacturer?

- <p>Yes, you can buy recycled aluminum sheets from local suppliers or manufacturers. Many businesses specialize in recycling and repurposing materials, including aluminum. To find a local supplier, you can search online directories or use business listing services. Additionally, contacting local recycling centers or metalworking businesses may provide leads on available recycled aluminum sheets. It's important to consider the quality, certifications, and environmental impact of the recycled materials when making your purchase.</p>

- Q: Whether its strong or not, im looking to get grime like stains out of my aluminum rims. It looks like they can be worked out after time, but i dont think i want to risk acidic products because im not 100% sure if theres a clear coat (i have eagle 077s if that helps!). I have read weird ideas from buffing with baby oil to brake cleaner since its super strong but dont wanna tear up my nice new wheels! Any input is greatly appreciated

- Aluminum Wheel Cleaner

- Q: Can the aluminum sheets be used for manufacturing decorative trim?

- Yes, aluminum sheets can be used for manufacturing decorative trim. Aluminum is a versatile material that is lightweight, durable, and resistant to corrosion. It can be easily shaped and formed into various decorative designs and patterns. Additionally, aluminum can be coated or painted in different colors to enhance its aesthetic appeal. Therefore, aluminum sheets are a popular choice for manufacturing decorative trim in various industries, including architecture, automotive, and interior design.

Send your message to us

Aluminum Silicon Carbide Sheets - Special Alloy Extrusion Aluminum 1050 Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords