Solidworks Aluminum Weldment Profiles for Aluminum Window and Door Frame CNBM Hot Sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0.2

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminum Profile

Products Introduction of Aluminum Profile

Aluminum ProfileAluminum frame is made from aluminum and minerals. It's raw matrial for window frame, window frame, and other equipment frame. It's easy for construction, cost less, service longer than other materails. The size and design can be customerized.

Advantage of Aluminum Frame

-Build FLEXIBLE equipment, window, door.

-Bolt your structure together

-Build with Aluminum MORE EASILY

-Aluminum costs LESS

-Service life is more than 10 years

-Can be customerized

Specifications

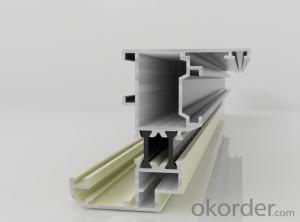

(1) Product: Aluminium Frame;

(2) Material: Alloy 6063/6061/6005/6060, T5/T6;

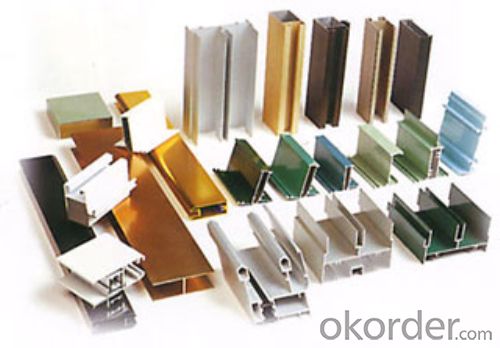

(3) Finish: anodizing, powder coating, wooden, electrophoresis or any color;

(4) Size: customized, same as drawings or samples;

(5) Standard: High-quality;

(6) Characteristics: strong, stylish, durable, corrosion-resistant.

Aluminium Alloy: 6063, 6061, 6005, 6060 Thermal Treatment: T5, T6

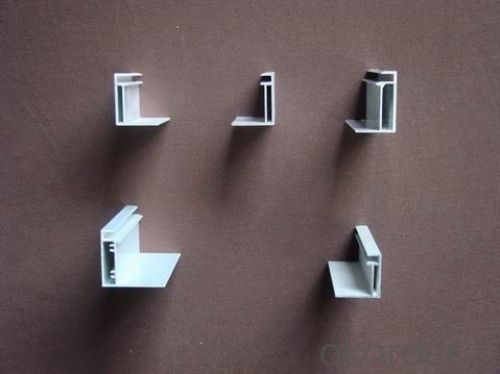

Section Shapes

I, U, T, C, Z, L, H, square, round, flat, hollow, t-slot, and other complicated shapes by custom design.

Surface treating

Mill / Anodizing (oxidation) / Sand blasting / Powder Coating / Electrophoresis / PVDFCoating / Wood effect.

Application

1) - for Window and door frames, for Wardrobe cabinet sliding doors, kitchen, for Building curtain glass walls

2) -for Fencing, Rail, Deck and Frame.

3) - for Solar panel frames, solar mounting / roofing brackets

4) - for Industry assembly lines equipment.

5) - for Heatsinks, for LED lighting.

7) - other by custom design size and dimension

FAQ

-What's your company profile?

We CNBM is the largest building material supplier of China. We are Chinese government owned corporation, which takes the 267th place in WOLD FORTUNE 500 CORPORATION. We own the largest prodcution base in North and South of China. With more than 15 warehouses and offices in different countries, our products sell very well all over the world. We have whole quality control system. We'll be your reliable partner.

-Which kind of payment do you usually support?

TT, LC at sight.

-Can you provide samples?

Yes, we provide free of charge samples, you just need to pay for the delivery.

Photos:

- Q: Are there any regulations or standards that aluminum profiles must meet?

- To ensure the quality and safety of aluminum profiles, they must adhere to various regulations and standards. The specific requirements vary depending on the application and industry. Here are some commonly followed regulations and standards: 1. ISO Standards: The International Organization for Standardization (ISO) has established several standards for aluminum profiles. These include ISO 9001 for quality management systems, ISO 14001 for environmental management systems, and ISO 9001 for occupational health and safety management systems. 2. ASTM International Standards: ASTM International provides standards for aluminum profiles used in construction, transportation, and other industries. These standards specify the chemical composition, mechanical properties, and dimensional tolerances that aluminum profiles must meet. 3. American National Standards Institute (ANSI) Standards: ANSI develops standards for aluminum profiles used in various applications. These standards address design, performance, and safety requirements. 4. European Standards (EN): In Europe, aluminum profiles must meet the criteria set by the European Committee for Standardization (CEN). These standards define the characteristics, dimensions, and tolerances of aluminum profiles used in construction, aerospace, automotive, and other industries. 5. National Regulations: Many countries have their own regulations governing the use of aluminum profiles. These regulations cover aspects such as fire safety, structural integrity, and environmental impact. Manufacturers, suppliers, and users of aluminum profiles must comply with these regulations and standards to ensure the quality, reliability, and safety of their products and applications. Adhering to these standards helps maintain consistency, interoperability, and customer confidence across various industries that use aluminum profiles.

- Q: How do I cut and shape aluminum profiles?

- To cut and shape aluminum profiles, you will need a few tools and techniques. Here is a step-by-step guide to help you accomplish this task: 1. Acquire the necessary tools: You will need a miter saw or a circular saw with a carbide-tipped blade suitable for cutting aluminum. Additionally, it is recommended to have a metal file, sandpaper, a deburring tool, and a tape measure. 2. Measure and mark: Use a tape measure to measure the desired length of the aluminum profile. Mark the location where you want to make the cut using a pencil or a marker. 3. Secure the aluminum: Place the aluminum profile securely on a workbench or a cutting surface. Use clamps or a vice to hold it firmly in place, ensuring it doesn't move during the cutting process. 4. Cutting the aluminum: Position the saw blade at the marked location and align it perpendicular to the aluminum profile. Start the saw and slowly guide it through the aluminum, applying steady pressure. Let the saw do the work without forcing it too hard, as excessive pressure can cause the blade to bind or chip. Take caution to wear safety goggles and gloves to protect yourself from any flying debris. 5. Smooth the edges: After cutting, you may notice sharp or rough edges on the aluminum profile. Use a metal file or sandpaper to smooth out these edges, ensuring a clean and safe finish. 6. Deburring: To remove any burrs or rough spots left from the cutting process, use a deburring tool. Run the tool along the cut edges, applying light pressure to smooth them out. 7. Shaping the aluminum: If you need to shape the aluminum profile, you can use a variety of methods. A common technique is to clamp the profile to a workbench and use a hammer or rubber mallet to bend it slowly and incrementally. You can also use specialized tools such as a metal brake or a bending machine for more precise shaping. 8. Finishing touches: Once you have cut and shaped the aluminum profile, clean it thoroughly to remove any debris or metal shavings. Inspect the profile for any imperfections and make any necessary adjustments before using it for your desired application. Remember to take appropriate safety precautions throughout the process, such as wearing safety goggles, gloves, and securing the aluminum profile properly to prevent accidents.

- Q: This question asks if aluminum profiles can be utilized in cold weather conditions and seeks an explanation for their suitability.

- <p>Yes, aluminum profiles can be used in cold climates. Aluminum is a lightweight and durable material that maintains its strength and structural integrity even in extreme low temperatures. It does not rust or corrode, which makes it ideal for use in environments with harsh weather conditions. Additionally, aluminum has good thermal conductivity, which allows it to dissipate heat effectively, but it also has low thermal expansion, meaning it does not expand or contract significantly with temperature changes. This characteristic helps prevent warping or cracking in cold climates. Properly designed and installed aluminum profiles can withstand the challenges of cold weather without compromising their performance or longevity.</p>

- Q: How do you cut and shape aluminum profiles?

- To cut and shape aluminum profiles, you can use various methods such as sawing, milling, drilling, or using specialized cutting tools. Sawing can be done with a hacksaw, circular saw, or miter saw, while milling involves using a milling machine to remove material and create desired shapes. Drilling is commonly used to create holes in the aluminum profiles. Additionally, specialized cutting tools like shears or punches can be utilized for specific cutting requirements. It is important to select the appropriate tools and techniques based on the profile's thickness, complexity, and desired outcome. Safety precautions and appropriate protective gear should always be used when working with aluminum.

- Q: Are aluminum profiles resistant to impact or vibration?

- Yes, aluminum profiles are generally resistant to both impact and vibration. Aluminum is known for its high strength-to-weight ratio and excellent durability. It can withstand external forces and impacts without easily deforming or breaking. Additionally, aluminum's natural properties make it inherently resistant to vibration. It has a high damping capacity, meaning it can absorb and dissipate vibrations, reducing their effects. This makes aluminum profiles an ideal choice for applications where impact or vibration resistance is required, such as in the construction, automotive, aerospace, and marine industries.

- Q: This question asks for a list of various fastening methods used to connect aluminum profiles to the structural frames of buildings.

- <p>There are several types of fasteners used to attach aluminum profiles to building frames, including: 1) Bolts and Nuts: Commonly used for strong, secure connections. 2) Rivets: Provide a permanent connection that is resistant to vibration. 3) Self-Tapping Screws: Can be used in materials without pre-drilling. 4) Structural Glue: Offers a strong bond and is often used in combination with mechanical fasteners. 5) Welding: Used for permanent, load-bearing connections, though not common for aluminum due to the risk of thermal distortion. 6) Clamps and Brackets: Used for temporary or adjustable connections. 7) Adhesive Tapes: Provide a quick and easy method of attachment, though not as strong as other methods. Each type of fastener has its own advantages and is chosen based on the specific requirements of the construction project.</p>

- Q: This question asks for methods to prevent aluminum profiles from rusting during the transportation process.

- <p>To prevent rusting of aluminum profiles during transportation, ensure proper packaging with moisture-resistant materials. Use protective films or covers to shield the profiles from direct contact with moisture and humidity. Maintain a controlled environment in the transport vehicle, avoiding high humidity and condensation. Regularly inspect the profiles for any signs of moisture or damage and address them promptly. Additionally, consider using rust inhibitors or anti-corrosion coatings on the aluminum profiles before packaging. Always handle the profiles with care to avoid scratches or damage that could lead to rusting.</p>

- Q: What is the difference between aluminum profile and sheet metal?

- Aluminum extrusions can be produced by extrusion or casting. In contrast, the aluminum sheet is flat, mainly for all types of surface.

- Q: How do you select the appropriate aluminum profile for a specific application?

- Selecting the appropriate aluminum profile for a specific application involves considering several key factors. Firstly, it is important to understand the requirements and specifications of the application. This includes considering factors such as the load-bearing capacity, structural integrity, and overall functionality needed for the application. Next, it is crucial to evaluate the characteristics of the available aluminum profiles. This involves considering factors such as the alloy composition, strength, hardness, and corrosion resistance. Each application may require specific properties to ensure optimal performance and durability. Additionally, it is important to assess the dimensions and shape of the aluminum profile. This involves considering factors such as the length, width, and thickness required for the application. The shape of the profile, whether it is square, rectangular, or custom-designed, should also be taken into account. Another aspect to consider is the surface finish of the aluminum profile. Depending on the specific application, the surface may need to be smooth, textured, or treated to enhance its appearance or provide additional protection against wear, abrasion, or corrosion. Furthermore, it is essential to consider the availability and cost of the chosen aluminum profile. Evaluating the availability of the required profiles from different suppliers and assessing their cost-effectiveness is crucial to ensure that the chosen profile aligns with the budget and project timeline. Lastly, seeking expert advice and consulting with professionals who have experience in aluminum profiles for specific applications can be beneficial. They can provide valuable insights and recommendations based on their knowledge and expertise. In conclusion, selecting the appropriate aluminum profile for a specific application involves considering factors such as the application's requirements, the characteristics of the aluminum profile, dimensions and shape, surface finish, availability, cost, and seeking expert advice. By carefully considering these factors, one can choose the most suitable aluminum profile that will meet the requirements of the application effectively.

- Q: and I know the meaning of 125MN is 12500 tons. I want to know if 125MN is a English an abbreviation of the word, if it is, then what is he, if he is not that what is the meaning?

- MN is an international unit, said the bull"125MN's extruder is 12500T's extruderBloomberg metal Forum

Send your message to us

Solidworks Aluminum Weldment Profiles for Aluminum Window and Door Frame CNBM Hot Sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0.2

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords