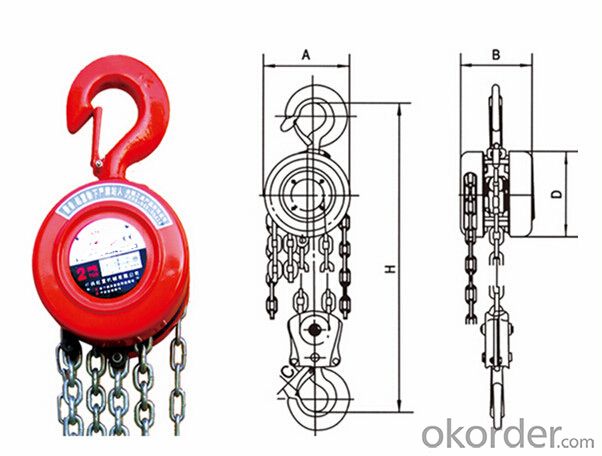

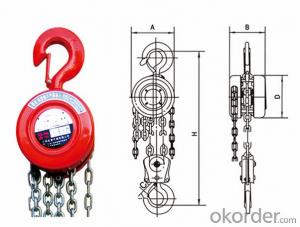

50T*3m heavy duty VC-B manual chain hoist

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 200 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Condition: New

Place of Origin: Hebei, China (Mainland)

Brand Name: CNBM

Model Number: VC-B50T

Usage: Construction Hoist

Power Source: Hand Chain

Sling Type: Chain

Maximum Lifting Weight: 75 tons

Maximum Lifting Height: 12M

Lift Speed: lifting speed

Certification: CE&GS

Warranty: one year

Capacity: 50tons

No. of load chains: 12

Load Chain Diameter: 9mm

Color: red or yellow

Description: VC-A Best price hoist

Test Load: 75T

n.w: 1092kg

Standard lift height: 3m

Main Features

•Superior rigidity makes the hoist dust-proof and water-pfoof;

•Severe environment and work condition are acceptable;

•Simple structure and few components

•Adopt Janpanese FEC chain;

•To greatly enhance the performance of the fatigue and wearresistance.

•Limit protection adevice can avoid overload occerring;

•Hook bolt can prevent the rigging accidently from slip;

•Moter is equipped with thermal protection device;

•limit contactors are set in the machine.

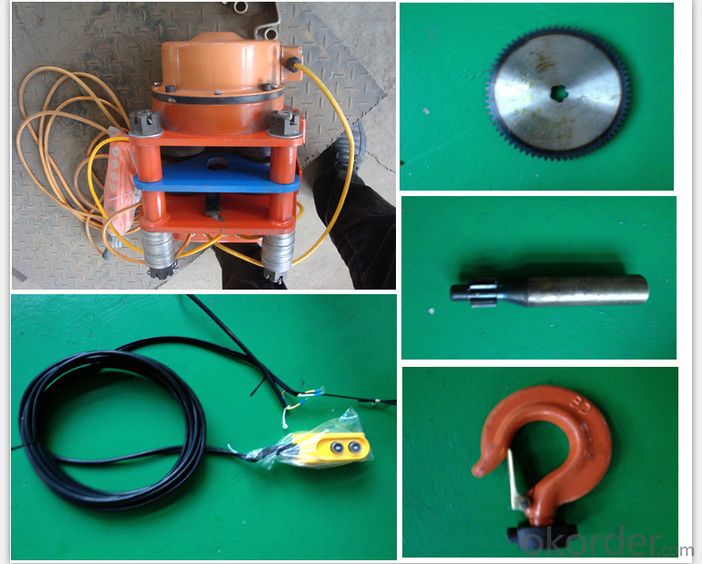

Product Picture

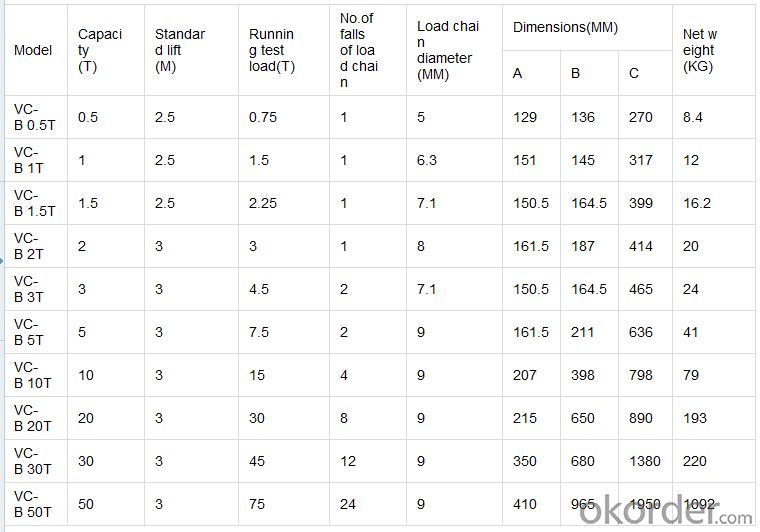

Parameter List

manual chain hoist

1. OEM

2. Certificated,CE,GS,ISO

3. 1 year guarantee

4. manual chain hoist 50 ton

50T*3m heavy duty VC-B manual chain hoist

Main Performances and Technical Specifications

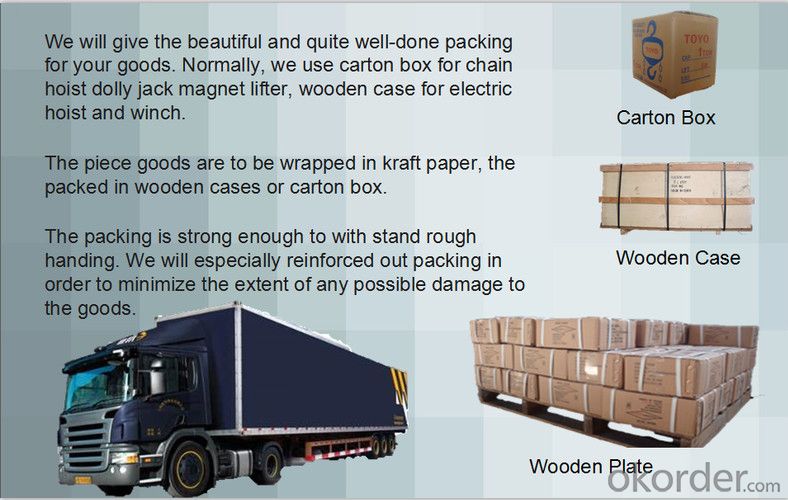

Our Service

1.We can make special sample according to the customer’s requirement.

2. We have more than 20 professional technical team, provide best after-sales service

3. Fast delivery time

4. We have CE, ISO9001 and GS certification.

- Q: What is the difference between cable stayed bridge and suspension bridge?

- The main weight of a bridge is not the car or train on it, but the road itself, that is, the road we see. Now let's analyze this:We analyze it with a pylon. The two sides of the pylon are symmetrical stay cables which connect the main beam of the pylon through the stay cables. Now suppose that only two towers on both sides of the cable, symmetrical each one of the two cables subjected to beam gravity, two symmetrical of the cable along the direction of the force, according to the stress analysis, the stress can be decomposed into a horizontal and vertical force to a downward force a vertical force; and the same on the right side of the force can be decomposed into the right level of a downward force; the two force is symmetrical, so the two level of the left and right horizontal force cancel each other out,

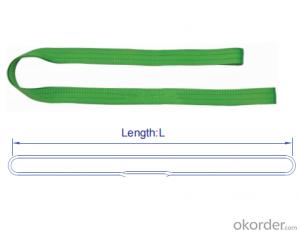

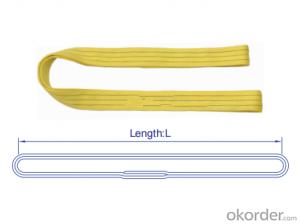

- Q: What is the influence of lifting angle on rigging?

- The vertical lifting is the best scheme for lifting. The smaller the angle between the sling and the vertical is, the greater the angle is, the greater the force the sling will bear. The sling will be easily broken off, which will lead to an accident, which is for reference only

- Q: Do cranes have the same wire ropes, slings, slings and cables?

- A steel wire rope is a common wire rope, and a sling is a special tool for lifting some goods. The sling is a sling tool made of wire ropes

- Q: Why do not different kinds or different sizes of slings and slings are used together?

- Choose proper slings and slings according to the specific conditions of the heavy loads; no heavy weights are allowed to be attached directly with the hooks, and no different kinds are allowed

- Q: What's the catch?

- Slings are ropes made of wire or synthetic fiber, used for hoisting.

- Q: What does the inspection of rigging involve?

- The crane used in atmospheric environment, preferably manganese phosphide coating, steel wire rope, heavy corrosive environment, preferred hot-dip galvanized double phosphating steel wire rope, priority wire rope in sea water. Please note that at the time of purchase, in the purchase invoice must indicate the name of wire rope, such as phosphate coated wire rope or 316 stainless steel wire rope, prevent illegal infringement of their legitimate rights and interests of enterprises, to counterfeit products in addition, patent products are generally in the rope on the outer packing is patent spraying mark, warranty book should be the main technical indicators, such as the phosphating film type and weight (film has an important influence on the weight of phosphating film size, wear resistance and corrosion resistance of the service life of the wire rope, for reference only)

- Q: What torture refers to the lever and the sling

- The sling hanging and torture half pig "(only one side of the body hanging victims), pawn (tied hanging arm and feet) and so on, all belong to the suspension of torture throughout human skin nerve endings, the feeling is very sensitive, in the daily life of people on the outside of the pain, is the nerve end suspension shoot at work. Some nerve endings, such as fingers, toes, sexual organs, etc., are more acute and abnormal. The distribution of the human nerve network also forms many subcutaneous sensitive areas, such as the two sides of the spine, the armpit, the medial thigh, the two rib, and so on. Therefore, the users of torture also torture people according to these physiological characteristics of the human body, and bring great suffering to the sufferers with more labor-saving means. The vast majority of the torture we know fall into this category, and the torture against women is basically the same.

- Q: Ceiling installation does not allow the use of air nails?

- (1) construction materials: common materials are as follows.Wood (different specifications of water, wood, water board), aluminum alloy (plate, profile), steel (steel, flat steel, steel plate), mainly as supporting components.Plastic, plexiglass plate, glass partition plate, outer decorative veneer and heat dissipating plate, copper plate and electrochemical aluminium plate as decorative component.Other accessories such as screws, nails, rivets, finished lamps, adhesives and so on.(2) construction tools: pliers, screwdrivers, hammers, saws, electric hammer, hand according to the curve, a ruler, paint etc..

- Q: What are the specifications for the length, length, and method of operation of the wire rope?

- Users need high quality steel wire rope, it should be long life and high quality stable and reliable wire rope.

- Q: Why are the suspension bridges a main cable, even a n multi sling, not a bridge directly from the tower?

- The main weight of a bridge is not the car or train on it, but the road itself, that is, the road we see. Now let's analyze this:We analyze it with a pylon. The two sides of the pylon are symmetrical stay cables which connect the main beam of the pylon through the stay cables. Now suppose that only two towers on both sides of the cable, symmetrical each one of the two cables subjected to beam gravity, two symmetrical of the cable along the direction of the force, according to the stress analysis, the stress can be decomposed into a horizontal and vertical force to a downward force a vertical force; and the same on the right side of the force can be decomposed into the right level of a downward force; the two force is symmetrical, so the two level of the left and right horizontal force cancel each other out,

Send your message to us

50T*3m heavy duty VC-B manual chain hoist

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 200 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches