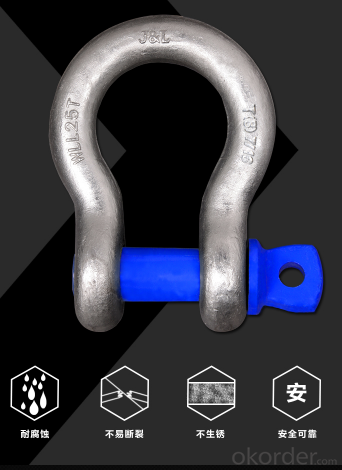

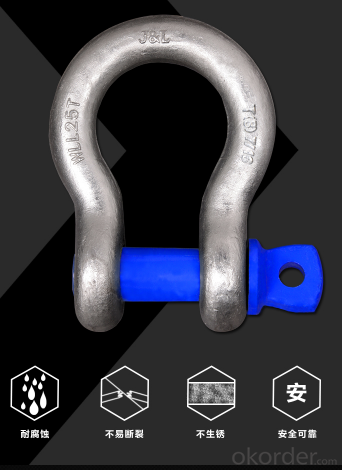

Grade T8 Bow ShackleBX,Grade T8 Bow ShackleBW

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Forging Rigging

SHACKLES

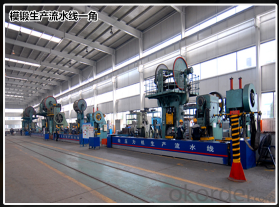

The forging rigging factory . is the largest production base for forging rigging in Asia with advanced forging, heat treatment,surface coating and nondestructive testing equipment and the most advanced production technology.

Main forging equipment :5T size free forging hydraulic hammer,4000t、2500t、1000t size friction press machine and 750kg ~ 1000kg size air forging hammer etc. We also researched and developed 400t、1000t、1500t、2000t size bending machine. The annual producing

capacity is 20000t.

The shackles (both body and pin) we produce are made of high quality alloy steel through advanced production line and intermediate frequency furnace heat treatment. It is characterized by high-intensity, good toughness, small volume, light weight, beautiful appearance and good durability.

Product category: Flat shackle, Large WLL shackle with circular cross-section, Bow shackle, D shackle etc.

Production range: 0.5t-2000t.

- Q: Where should I pay attention to the formwork?

- When the welded steel bar and the formwork are installed together, the following requirements shall be met:The formwork must be fixed on the joint of the load-bearing welded steel frame;When installing the reinforcing steel formwork assembly, the sling shall be tied up according to the hanging point designed by the template.

- Q: 20 tons sling rope, steel wire or chain?

- The main - phosphating coating steel wire rope, galvanized steel wire, stainless steel wire rope and coated steel wire rope wire rope varieties, for reference only

- Q: What is the name of the wire above the train?

- The catenary provides 25 thousand volt power frequency alternating current for the locomotive, according to the locomotive model difference, adopts the direct step-down, the frequency conversion power supply or the AC and DC conversion power supply, this is mainly for the speed regulation convenience.

- Q: Requirements and matters needing attention in hoisting

- Hoisting tower tank by using rotary method or down method, wrist hinge at the bottom of the tower installation must have the ability level of the thrust generated resistance during lifting, the lifting process of the tower body around the ropes must be reliable, the tower height of the rotary position, slowly falling into the foundation, avoid accidents and deformation.

- Q: Ceiling installation does not allow the use of air nails?

- (1) construction materials: common materials are as follows.Wood (different specifications of water, wood, water board), aluminum alloy (plate, profile), steel (steel, flat steel, steel plate), mainly as supporting components.Plastic, plexiglass plate, glass partition plate, outer decorative veneer and heat dissipating plate, copper plate and electrochemical aluminium plate as decorative component.Other accessories such as screws, nails, rivets, finished lamps, adhesives and so on.(2) construction tools: pliers, screwdrivers, hammers, saws, electric hammer, hand according to the curve, a ruler, paint etc..

- Q: What are the precautions for rigging in hoisting works?

- 1. develop good hoisting habits and plan how to hang, lift and unload before lifting.2. prepare: determine the weight of the hanging object and its center of gravity, read the attached document carefully, mark the lifting point and weight data. Only when the center of gravity has been determined can the hook be hung at the right place!3. the crane operator shall be informed of the weight of the suspended object.4. the crane hook shall be hung vertically above the center of gravity of the suspended object.5. lifting heavy pieces, both to avoid damage to lifting objects, but also to prevent damage to the rigging itself. The following conditions shall be observed in order to avoid rotation or fall:(a) single leg rigging, the lifting point shall be perpendicular to the center of gravity of the lifting object.(b) if it is a two leg rigging, the suspension point shall be on either side of the lifting object, with the lifting point above the center of gravity.(c) if it is a three leg and four leg rigging, the suspension point shall be evenly located at the center of gravity of the lifting object, and above the center of gravity of the suspended object.Attention must be paid to the lifting angle, between the vertical and the leg): the greater the lifting angle, the smaller the lifting capacity. Lifting angles of more than 60 degrees are absolutely not allowed!

- Q: What are the selection principles for lifting cranes?

- It can adapt to the conditions of road, hoisting, plane layout and equipment, machines and tools, and give full play to its technical performance.

- Q: Slings and rigging manufacturers, which cost-effective?

- Phosphating coating of steel wire rope than plain steel wire rope has long service life, lower cost, better stability, phosphating coating of steel wire rope is patent technology production, because the demand is more difficult to buy, to ask the producer of several wire rope, please note in the purchase, purchase invoice must indicate the name of wire rope, such as phosphate coated wire rope to prevent illegal enterprises, infringement of their legitimate rights and interests, in addition, patent products are generally in the rope on the outer packing of a patent spraying label, warranty should be the main technical indicators, such as the phosphating film type and film weight

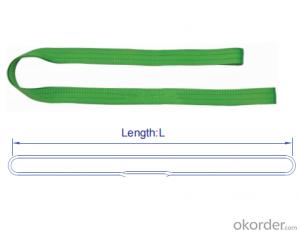

- Q: How to choose the right sling?

- Commonly used slings and slings are lifting belts, lifting chains and wire ropes. Slings and slings must be matched with lifting equipment, such as 5 tons or 10 tons. Cranes shall be marked with maximum lifting weight. Lifting belt will not damage the hoisting object but poor wear resistance, easy maintenance but large weight lifting chain, rope buckle range but the broken wire after easily scratch objects and operators, each have advantages and disadvantages, to meet their own needs is the best lifting.Phosphating coating of steel wire rope production technology patent, give priority to the use of manganese or zinc manganese phosphating, and smooth steel wire rope production process comparison, just increase the steel wire wear phosphating process, phosphating of steel wire surface after the abrasion resistance and corrosion resistance is greatly improved, the use of direct phosphating steel wire twisting steel wire rope (steel wire after phosphating not drawing). The fatigue test data show that the fatigue life of the phosphating coating of steel wire rope is about 3-4 times the same structure of plain steel wire rope, wire rope is 2-3 times of imports (laboratory comparable conditions) with the research on the wear resistance of phosphating, and greatly enhance the possibility of. Manganese phosphating is wear resistant phosphating, which can completely solve the wear problem in the use of wire rope.

- Q: Which sling manufacturer is more reliable?

- A variety of commonly used wire rope phosphating coating steel wire rope, galvanized steel wire, stainless steel wire rope or coated steel wire rope, the use of atmospheric environment, patented technology to produce manganese phosphating coating of steel wire rope has the longest lifespan, heavy corrosion environment optimization of hot galvanized wire rope double - phosphating coating.

Send your message to us

Grade T8 Bow ShackleBX,Grade T8 Bow ShackleBW

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords