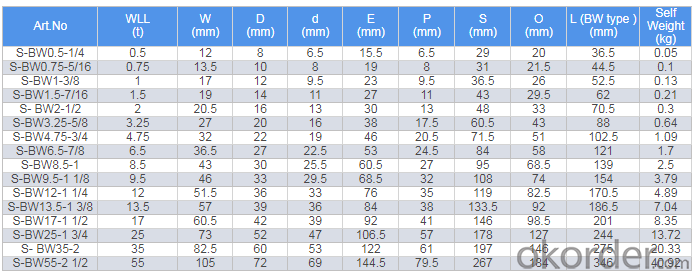

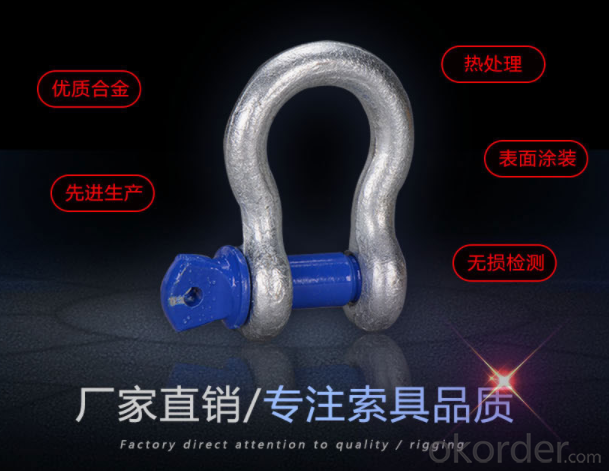

Grade S(6) Bow Shackle S6BW S6BW S6BW

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Forging Rigging

SHACKLES

The forging rigging factory. is the largest production base for forging rigging in Asia with advanced forging, heat treatment,surface coating and nondestructive testing equipment and the most advanced production technology.

Main forging equipment :5T size free forging hydraulic hammer,4000t、2500t、1000t size friction press machine and 750kg ~ 1000kg size air forging hammer etc. We also researched and developed 400t、1000t、1500t、2000t size bending machine. The annual producing

capacity is 20000t.

The shackles (both body and pin) we produce are made of high quality alloy steel through advanced production line and intermediate frequency furnace heat treatment. It is characterized by high-intensity, good toughness, small volume, light weight, beautiful appearance and good durability.

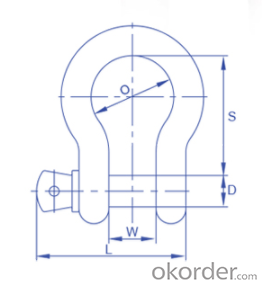

Product category: Flat shackle, Large WLL shackle with circular cross-section, Bow shackle, D shackle etc.

Production range: 0.5t-2000t.

- Q: What tools are slings in lifting operations? What is the function of the slings?

- A sling is also called a jack rope, a pair of rope or rope buckle. Hoisting works are more used, such as tying equipment, hanging blocks, stabilizing winches and so on. The utility model has the advantages of good quality and large elasticity, but the rigidity is large, and the bending is not easy, and once the bend is not easy to recover. Slings made of wire ropes of hemp core are not easy to work under high temperature.

- Q: Where should I pay attention to the formwork?

- When the interlayer height is greater than 5m, the truss formwork or the multi layer support formwork should be adoptedWhen the formwork is supported by a multi layer support, the support plate shall be smooth, the support shall be vertical, and the upper and lower support shall be on the same rigid central line.(5) when the segmental demoulding is adopted, the pivot of the bottom die shall be designed according to the template, and the sections shall be in the same plane, and the height difference shall not exceed 3mm.

- Q: What is the influence of lifting angle on rigging?

- Slings are usually steel wire ropes or chain slings. Wire ropes have manganese phosphating coating, steel wire rope, galvanized steel wire rope, manganese phosphating coating, steel wire rope is new technology product, and fatigue life is three times of smooth steel wire rope.

- Q: Requirements and matters needing attention in hoisting

- We often encounter equipment installation, transport and installation work, whether the derrick is lifting or hoisting machinery should pay attention to the following points: (1) the indigenous construction equipment for handling mobile rolling method, the rolling rod thickness should be consistent, should buetow annual row width is 50cm long, no gloves in rollers. While loading and unloading piping shall not be greater than 20 degrees slope, raceway erection should be smooth, solid, joints staggered, the rolling speed is not too fast, when necessary to use ropes.(2) in the course of installation, if problems are found, measures should be taken in time, and then continue to be hoisted after treatment.(3) large tower equipment for hoisting derrick, hoists joint operation, the hoist hoisting speed must be roughly the same, to ensure that the tower body of each suspension force roughly uniform, avoid the tower stress uneven deformation.

- Q: They are used for slings, ropes, chains, suspenders, hand hoists, right?

- A variety of commonly used wire rope phosphating coating steel wire rope, galvanized steel wire, stainless steel wire rope or coated steel wire rope.

- Q: What are the precautions for rigging in hoisting works?

- The sling shall not be allowed to repair or reprocess itself (welding, heating, heat treatment, surface chemical treatment). If such treatment must be carried out, it shall be sent back to the original manufacturer or under the guidance of the experts of the original factory.

- Q: What are the installation steps for crane beams?

- Crane operation is relatively dangerous, the installation of crane beam should be standardized to ensure the safety of crane operation. How many points should I pay attention to when installing the crane?:(1) the actual elevation of the corbel should be measured before the installation of the steel crane beam, so that the construction error of the elevation can be adjusted when the crane beam is installed, so as to prevent the error accumulation.The installation sequence of crane beam is as follows: installing crane beam, installing auxiliary truss and installing brake beam.(2) crane shall be used by slings, lashing or reliable clamps. The binding point shall be determined according to the weight and length of the crane beam. Generally, the angle of the sling shall be greater than 45 degrees at the ends of the center of gravity of the crane beam.(3) should be placed after the crane beam, the connecting plate is connected with the fixed edge plate and column crane girder structure, to prevent the crane hook loose after crane girder longitudinal and lateral movement of dumping.(4) crane beam correction should be performed in all bolts after installation, to prevent the installation of bolts when the crane beam shift change; prohibited welding in the crane girder under the flange and web on suspension and fixture.(5) adjust the elevation of the crane beam, correct the center line and span after titanium.

- Q: What are the specifications for the length, length, and method of operation of the wire rope?

- Users need high quality steel wire rope, it should be long life and high quality stable and reliable wire rope.

- Q: What is the safety factor of the wire rope as a motor lifting equipment, slings and slings?

- 3. stainless steel wire rope, the use of stainless steel wire rope system, such as 304 or 316 stainless steel, the price is relatively expensive, the stainless steel wire for manganese phosphating coating (stainless steel wire need special phosphating phosphating formula), you can use the same life greatly extended.

- Q: Types of slings for slings

- Metal slings are mainly wire ropes, slings, chains, slings and so on.

Send your message to us

Grade S(6) Bow Shackle S6BW S6BW S6BW

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords