WIRE ROPE WITH CRITICAL APPLICATIONS

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

- Q: What tools are slings in lifting operations? What is the function of the slings?

- Sling is one of the most common operation tools in hoisting operation.

- Q: What are the connections and differences between hooks, slings, rings and heavy truck rings in cranes? What are the hoisting designs?

- Round nylon lifting rope series: no connecting nylon lifting rope, two button nylon lifting rope, multi nylon lifting rope and shipAnchor rope, rope, paper rope, lifting rope, all kinds of transformer braided rope.

- Q: Where should I pay attention to the formwork?

- In the case of cast in place multi-storey houses and structures, the method of segmental formwork shall be adopted, and the upper formwork and its support shall be installed and shall meet the following requirements:The lower floor shall bear the load-bearing capacity of the upper layer or support with the support;The column of the upper bracket shall be used for the column of the lower layer bracket and the padding plate shall be laid;When the suspension formwork and truss formwork method are adopted, the supporting capacity and stiffness of the supporting structure must meet the requirements.

- Q: Is rope sling good business and high profit?

- 1. phosphating coating steel wire rope, steel wire by manganese or zinc manganese phosphating, corrosion resistance and wear resistance steel rust resistance comprehensive jump, life is the same structure of plain steel wire rope 3 times (note the use of zinc phosphating and drawing rope with distinction, although Tianjin bonderizing Jiangsu have been a number of production enterprises, there is still a shortage of supply and demand)2. galvanized steel wire, hot-dip galvanized and galvanized3. stainless steel wire rope, 304 or 316 stainless steel4. coated steel wire rope, wire rope on the basis of the outer coating of polyethylene or polypropylene5. smooth steel wire rope, will be phosphating coating steel wire rope completely eliminated.

- Q: Do cranes have the same wire ropes, slings, slings and cables?

- To be exact, different things are very relevantThe cable belongs to the sling and belongs to the spreaderA wire rope can be made into a wire rope rigging

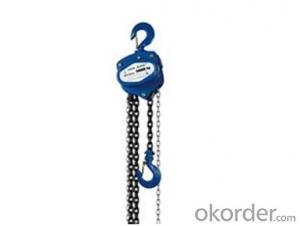

- Q: They are used for slings, ropes, chains, suspenders, hand hoists, right?

- The use of atmospheric environment, patented technology to produce manganese phosphating coating of steel wire rope has the longest lifespan, manganese phosphating coating can greatly improve the wear resistance and corrosion resistance of the steel wire surface, the fatigue life of the phosphating coating steel wire rope is 3-4 times of smooth wire rope, with the research on the wear resistance of the phosphating liquid, as well as to further improve the possibility of. According to the current market price of the phosphating coating steel wire rope, phosphating coating steel wire rope daily use cost is just plain steel wire rope about thirty percent of phosphating coating steel wire rope is a substitute for plain steel wire rope upgrade, for reference only.

- Q: What's the catch?

- Slings are ropes made of wire or synthetic fiber, used for hoisting.

- Q: What does the inspection of rigging involve?

- At present, the wire ropes can detect the broken wires and wear of the wire ropes and display them digitally.

- Q: Which sling manufacturer is more reliable?

- A variety of commonly used wire rope phosphating coating steel wire rope, galvanized steel wire, stainless steel wire rope or coated steel wire rope, the use of atmospheric environment, patented technology to produce manganese phosphating coating of steel wire rope has the longest lifespan, heavy corrosion environment optimization of hot galvanized wire rope double - phosphating coating.

- Q: What are the specifications for the rigging?

- The wire rope for the first time in the field of fretting fatigue control measures is the phosphating coating steel wire rope patent technology production, steel wire after manganese phosphating or zinc manganese wear-resistant steel wire surface treatment, corrosion resistance to enhance, not easy to wear and corrosion fatigue life of the steel wire rope large increase, fatigue life is three as structure of plain steel wire rope, the highest value of contrast test has reached an alarming four times, can be verified by fatigue test, fatigue test machine if they have on their own to do comparative tests, this test results most credible, the service life of wire rope and the fatigue life is directly proportional to the fatigue life, long service life with the proportion of prolonged use of lower cost, better stability, phosphating coating of steel wire rope is patent technology production

Send your message to us

WIRE ROPE WITH CRITICAL APPLICATIONS

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords