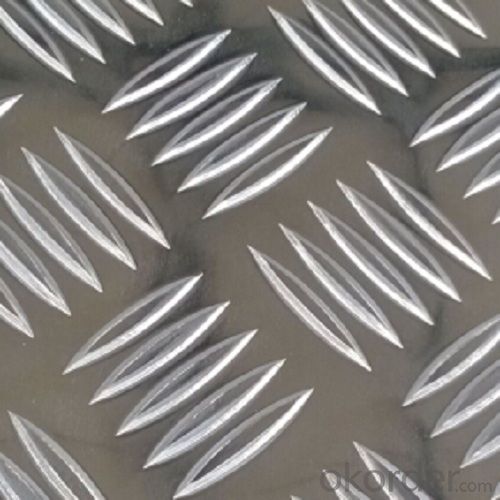

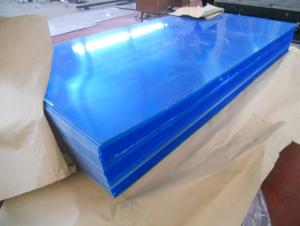

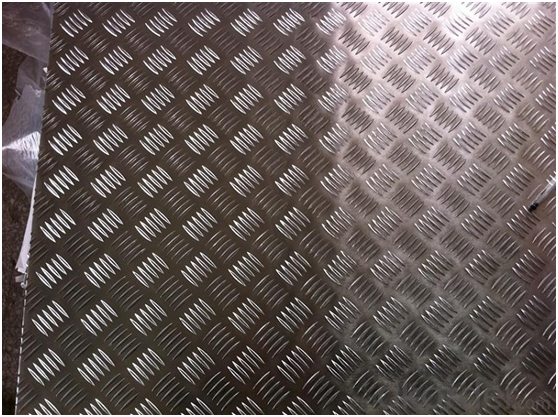

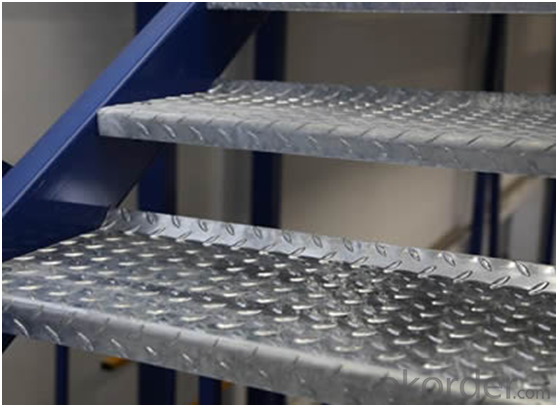

Smooth Aluminum Siding Sheets with Various Patterns Tread/Checker Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

l Production Introduction

1. Commodity: Factory manufacture low price high quality aluminum dimond plate sheets

2. Alloy No.: 050 1060 1100 3003 3004 3104 3005 3105 5005 5052 8011

3. Size: Thickness: 0.15-5.00mm(Tolorance±0.02mm)

Width:200-1600mm(Tolorance±1mm)

Length: 500-1500mm(Tolorance±1mm)

4. Application:

1) air plane, refrigerators ,audio equipment

2) building materials: ceilings, walls

3) telephones, digital cameras

4) plastic composite board, aluminum and plastic pipe

5.Month Capacity: 5000MT/Month

6.Pattern: 2 bars, 3 bars, 5 bars, diamond bar

l Packaging & Delivery

Packaging detail: First, plastic cloth; Second, Pearl Wool ; Third, wooden cases with dry agent ,without fumigation, wooden pallets

Delivery detail: Within 25days

l CNBM Images

l Product Images and Application

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 2.5 tons

Q: What are your payment terms?

A: We accept L/C, T/T.

- Q: What is the thickness of an aluminum sheet?

- The thickness of an aluminum sheet can vary depending on its specific application and desired properties. Standard aluminum sheet thicknesses can range from 0.2 millimeters (0.008 inches) to several millimeters (0.1 inches or thicker).

- Q: What types of aluminum sheets are recommended for outdoor applications?

- <p>Yes, there are specific types of aluminum sheets suitable for exterior use. These include aluminum sheets with a protective coating, such as anodized aluminum, which offers enhanced resistance to corrosion and weathering. Additionally, aluminum sheets with a Kynar 500庐 PVDF coating are highly resistant to UV rays, making them ideal for exterior applications. Marine-grade aluminum is also recommended for exterior use due to its superior corrosion resistance, especially in coastal areas. These types of aluminum sheets are designed to withstand harsh outdoor conditions and maintain their integrity over time.</p>

- Q: What are the different fabrication methods used for aluminum sheets?

- Aluminum sheets undergo various fabrication methods, each presenting its own advantages and applications. Rolling, extrusion, casting, and stamping are among the most commonly employed techniques. Rolling, the most prevalent method, entails passing the aluminum through a series of rollers to reduce thickness and form a flat sheet. This approach allows for precise control over sheet thickness and shape, rendering it suitable for an array of applications, from packaging to building materials. Another well-received method is extrusion, where heated aluminum is pushed through a die to create a specific shape or profile. This technique is commonly employed to manufacture intricate shapes like tubes, rods, and channels. Extruded aluminum sheets exhibit high strength and durability, making them appropriate for structural applications in construction and automotive industries. Casting involves pouring molten aluminum into a mold, allowing it to solidify. This method is frequently used for producing intricate shapes that are challenging to achieve through other means. Cast aluminum sheets can boast unique textures and designs, making them popular for decorative purposes. Stamping utilizes a press to shape the aluminum sheet by exerting pressure and forming it into the desired shape. This technique is commonly utilized for creating precise, small parts such as brackets, connectors, and electrical components. Stamped aluminum sheets offer exceptional dimensional accuracy and can be produced in large quantities at a relatively low cost. Additionally, other fabrication techniques such as welding, bending, and laser cutting can be employed to further process aluminum sheets and craft custom shapes and designs. In conclusion, the choice of fabrication method for aluminum sheets relies on the desired application, required properties, and complexity of the desired shape. Each method possesses unique advantages and capabilities, enabling a broad range of possibilities in aluminum sheet fabrication.

- Q: Aluminum plate 90 degree bending, why cracking?

- Should be the aluminum sheet material and the state of the wrong, I do not know what brand of aluminum plate, with 1060 Aluminum plate, the state: soft 90 degrees bending, not cracking

- Q: This question asks about the various grades of aluminum sheets and the impact of these grades on their pricing.

- <p>Aluminum sheets are categorized into different grades based on their composition and properties. The most common grades include 1000 series (99% pure aluminum), 3000 series (aluminum-manganese alloys), 5000 series (aluminum-magnesium alloys), and 6000 series (aluminum-magnesium-silicate alloys). Each grade has unique characteristics affecting their applications, such as corrosion resistance, strength, and formability. The price of aluminum sheets varies with the grade due to differences in purity, alloying elements, production complexity, and market demand. Purity and the addition of alloying elements can increase the cost, while the availability and demand in the market also influence pricing. For instance, 1000 series sheets are generally cheaper due to their high purity and lack of alloying, while 6000 series sheets, known for their strength and durability, command a higher price.</p>

- Q: Do these frames rust? For example here is a link. But I am genuinely curious because in swimming pools, the hand rails going into the swimming pool have the same finish as this bike frame and they have white corrosion marks. Thank you in advanced

- pool rails will not be the same thing as bike aluminum bikes are not immersed in water aluminum cannot rust though it might corrode in salt water or air wle

- Q: What are the different methods of surface etching for aluminum sheets?

- There are several methods of surface etching for aluminum sheets, including chemical etching, laser etching, and mechanical etching. Chemical etching involves applying an etchant solution to the surface of the aluminum sheet, which selectively removes material to create the desired pattern or design. Laser etching uses a high-energy laser beam to vaporize or ablate the surface of the aluminum, creating precise and detailed patterns. Mechanical etching involves using physical tools or abrasive materials to physically remove material from the surface, typically resulting in a more textured or roughened finish.

- Q: Are 101 aluminum sheets suitable for heat sinks?

- No, 101 aluminum sheets are not suitable for heat sinks. Heat sinks are designed to dissipate heat and therefore require materials with high thermal conductivity. 101 aluminum has a lower thermal conductivity compared to other aluminum alloys commonly used for heat sinks, such as 6061 or 6063. These alloys have better thermal conductivity properties, allowing them to effectively transfer heat away from the heat source. Therefore, it is recommended to use aluminum alloys specifically designed for heat sinks to ensure optimal heat dissipation and cooling performance.

- Q: What is the reflectivity of aluminum sheets?

- Aluminum sheets possess a considerably high reflectivity, typically falling within the range of 80% to 90%. Such elevated reflectivity can be attributed to the sleek surface and distinctive characteristics of aluminum, enabling it to effectively bounce back light and other electromagnetic waves. Consequently, aluminum sheets find wide application in scenarios that necessitate heightened reflectivity, including the creation of reflective surfaces, solar panels, and mirrors. Furthermore, the reflectivity of aluminum can be augmented even more by employing a reflective coating or meticulously polishing the surface.

- Q: My new home has a mix of copper and aluminum wiring. My mother used a shop vac in one of the recepticles last week and blew two of them in my bedroom. Then this weekend my brother was replacing my exhaust fan in the bathroom and that proceeded to blow the entire bedroom and bathroom including ceiling fans, lights and all recepticles. Does anyone have any ideas?

- Home Depot sells quality aluminium receptacles. Not doubting your father totally but an electrician needs to check the inside of the panel. A number of things can go and the breaker wont be effected. If the problem is not within the panel an electrician can trace the dead circuits and isolate the problems. Hopefully your new but old home does not have any concealed electrical boxes. Sometimes in older homes the previous owner may have added some electrical items and any Joe could have did it. Believe me I've seen a lot in my 15 years of practice.

Send your message to us

Smooth Aluminum Siding Sheets with Various Patterns Tread/Checker Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords