Smooth Aluminum Siding Sheets - 1100-H14 Aluminum Sheet and Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 9 m.t

- Supply Capability:

- 3000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Product Description

1010, 1050,1060,1100, 2024, 3003, 3005, 3105, 5052,5754,5083,6061,6063,8011, etc.

The temper is include H14, H22, H24, H44,H112,H114,etc.

2. Main features of the product

a.Competitive price

b.Frist-Class Service.

c. Shortest service.

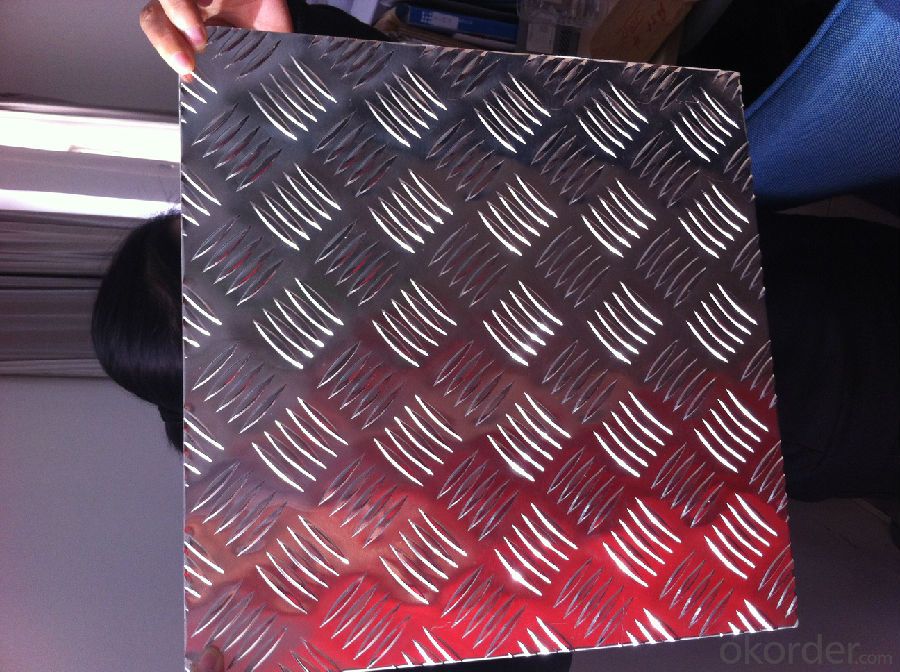

3. Image.

4. Product detailed sizes:

1000mm*2000mm, 1219mm*2438mm,1220mm*2440mm, 1250mm*2500mm,1500mm*3000mm, etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or others.

What is the width range?

---It is from 1000mm to 2500mm, etc.

What is the length range:

---It is from 2000mm to 6000mm, etc.

What is the MOQ for your products yet?

---Normally it is around 5 tons/each size.

How many tons did you export in one year?

---Normally it is around 9000 tons totally.

Where is your client from?

---Normally it is from Japan, USA, ENGLISH, SINGAPORE, ETC.

What is your mainly products?

---Normally they are aluminum sheet, checkered sheet, mirror finish aluminium sheet, aluminum casting coil, etc.

- Q: Are 101 aluminum sheets suitable for cryogenic applications?

- No, 101 aluminum sheets are not suitable for cryogenic applications.

- Q: The question asks about the duration aluminum sheets can last and how this compares to the lifespan of other materials.

- <p>The lifespan of aluminum sheets can vary significantly based on the environment and usage conditions. Generally, aluminum sheets have a long lifespan, often lasting 50 years or more without significant deterioration when properly maintained. This durability makes aluminum sheets a popular choice for construction and manufacturing applications. Compared to other materials, such as steel, aluminum is lighter and more resistant to corrosion, which can extend its lifespan in certain environments. However, steel may be more suitable for applications requiring high strength, while aluminum excels in applications where weight and corrosion resistance are priorities.</p>

- Q: Can aluminum sheets be used for water tanks?

- Yes, aluminum sheets can be used for water tanks. Aluminum is a corrosion-resistant material and is commonly used in the construction of water tanks due to its durability and ability to withstand harsh weather conditions.

- Q: What is the standard thickness of aluminum sheets used for constructing carports or garages?

- <p>The thickness of aluminum sheets commonly used for carports or garages typically ranges from 0.022 to 0.032 inches (0.56 to 0.81 mm). This range provides a balance between strength and cost-effectiveness. Thicker sheets offer greater durability and resistance to weathering, while thinner sheets are more affordable but may require more maintenance over time. The specific thickness chosen often depends on the design requirements, local weather conditions, and the intended lifespan of the structure.</p>

- Q: The minimum thickness of aluminum curtain wall is 2, 5mm or 3mm?

- The conventional design of single aluminum plate is up to 2.5 mm, the other I still haven't met,

- Q: What is the typical tensile strength of aluminum sheets?

- The typical tensile strength of aluminum sheets can vary depending on the specific grade or alloy being used. Generally, the tensile strength of aluminum sheets ranges from 20,000 to 50,000 pounds per square inch (psi). However, it is important to note that this is a broad range, and the exact tensile strength can be influenced by factors such as the thickness of the sheet, the manufacturing process, and any additional treatments or coatings applied to the aluminum. Therefore, it is recommended to consult the specifications provided by the manufacturer or supplier for accurate information on the tensile strength of a specific aluminum sheet.

- Q: Are aluminum sheets suitable for signage?

- Yes, aluminum sheets are suitable for signage. They are lightweight, durable, and weather-resistant, making them a popular choice for outdoor and indoor signage applications. Additionally, aluminum sheets can be easily customized, printed, and mounted, allowing for versatile and long-lasting signage solutions.

- Q: How does the surface roughness of aluminum sheet affect its performance?

- The surface roughness of an aluminum sheet can significantly affect its overall performance. The roughness of the surface refers to the irregularities, bumps, and texture present on the sheet's surface. These irregularities can be measured using various methods, such as Ra (arithmetical average roughness) or Rz (mean roughness depth). One significant impact of surface roughness on aluminum sheet performance is in its ability to bond or adhere to other materials. A smoother surface allows for better adhesion, whether it is through welding, gluing, or painting. When the surface is rough, it creates less contact area and reduces the strength of the bond. This is particularly crucial in applications where the aluminum sheet is used as a structural component or in manufacturing processes that require strong adhesion. Surface roughness also affects the sheet's ability to reflect light. A smoother surface reflects light more uniformly, resulting in a higher level of reflectivity. In contrast, a rough surface scatters light in multiple directions, reducing its overall reflectivity. This property is relevant in applications such as architectural cladding, where the desired aesthetic appearance may rely on the sheet's ability to reflect light consistently. Moreover, the surface roughness of aluminum sheets can impact their corrosion resistance. A smoother surface is less prone to corrosion as it provides fewer sites for corrosion initiation. On the other hand, a rougher surface may have micro crevices or grooves that can trap moisture, salts, or other corrosive substances, accelerating the corrosion process. In applications where corrosion resistance is critical, such as marine environments or outdoor structures, maintaining a smooth surface is essential. Lastly, surface roughness affects the sheet's mechanical properties. A rough surface can act as stress concentrators, leading to increased susceptibility to fatigue, cracks, or other mechanical failures. Smoother surfaces distribute stress more evenly, enhancing the sheet's overall strength and resistance to deformation. In conclusion, the surface roughness of an aluminum sheet plays a vital role in its performance. It impacts adhesion, reflectivity, corrosion resistance, and mechanical properties. Therefore, considering and controlling the surface roughness is essential in various applications to ensure optimal performance and longevity of aluminum sheets.

- Q: Can aluminum sheets be an alternative to glass in certain applications?

- Yes, aluminum sheets can be an alternative to glass in certain applications. Aluminum sheets offer several advantages over glass, making them a suitable choice in specific scenarios. Firstly, aluminum sheets are lightweight and durable, making them ideal for applications where weight is a concern, such as in aerospace or automotive industries. Glass, on the other hand, is relatively heavy and brittle, which can limit its use in certain environments. Additionally, aluminum sheets have excellent corrosion resistance, making them suitable for applications in marine or coastal environments where glass may deteriorate over time due to exposure to saltwater. Aluminum sheets also have a high strength-to-weight ratio, allowing for greater design flexibility and structural integrity compared to glass. Moreover, aluminum sheets can provide better thermal insulation properties compared to glass. They offer improved heat transfer resistance, which can be advantageous in applications where temperature control is crucial, such as in the construction industry. Furthermore, aluminum sheets can be more cost-effective than glass in certain applications. The production and installation costs of aluminum sheets are often lower compared to glass, making them a more economical choice for large-scale projects. However, it is important to note that glass still has its own unique properties and advantages that make it the preferred choice in many applications, such as its transparency and optical clarity. Glass also offers better resistance to scratches and chemical corrosion compared to aluminum sheets. In conclusion, while aluminum sheets can be a viable alternative to glass in certain applications due to their lightweight, durability, corrosion resistance, thermal insulation properties, and cost-effectiveness, the choice between the two materials ultimately depends on the specific requirements and constraints of the application in question.

- Q: Can aluminum sheets be used for insulation purposes?

- Yes, aluminum sheets can be used for insulation purposes. Aluminum has a high thermal conductivity, which means it is a good conductor of heat. However, when used for insulation purposes, aluminum sheets are typically combined with other materials to create a more effective insulation system. One common example is aluminum foil insulation, where a layer of aluminum foil is combined with other materials such as foam or fiberglass to create a barrier against heat transfer. The reflective properties of aluminum also make it useful for reflecting radiant heat, further enhancing its insulation capabilities. Overall, while aluminum sheets alone may not provide sufficient insulation, they can be used effectively in combination with other materials to create insulation systems for various applications.

Send your message to us

Smooth Aluminum Siding Sheets - 1100-H14 Aluminum Sheet and Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 9 m.t

- Supply Capability:

- 3000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords