Slope Reinforcement Geogrids - Good Toughness Polyethylene Geogrid High Strength Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction

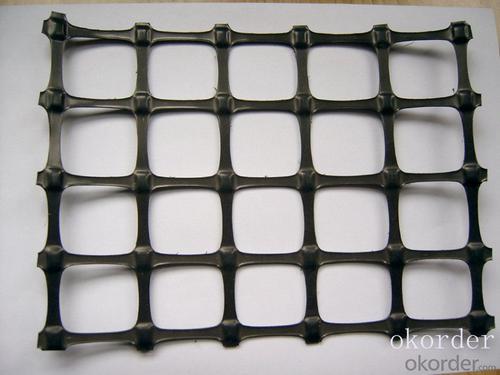

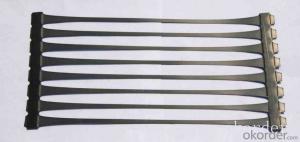

The outlook of the biaxial geogrid is net work structure like a square. It uses polyester as its raw material and is made of high molecular polymer through extrusion, formed and punched before longitudinally and laterally stretched. This kind of material has a high tensile longitudinally and horizontally, which can be used to reinforce the basement.

Geogrids form a distinct category of geosynthetics designed for reinforcement.

Fiberglass Geogrid with CE Certificate

We can produce fiberglass geogrid with tensile strength 30x30kn--300x300kn/m. mesh size can be 25.4x25.4mm or 12.7x12.7m ,50x50mm.

Type:

Geogrids

Material:

Fiberglass

Coating:

asphalt

feature:

High flexibility and large range

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

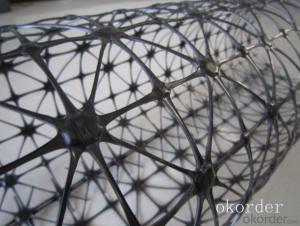

A: Yes, please check the pictures:

- Q: What is the main purpose of unidirectional plastic geogrid?Plastic geogrid production

- Unidirectional geogrid reinforced asphalt pavement or cement: Geogrid laying layer at the bottom of asphalt or cement, can reduce rutting depth, prolong the fatigue life of the pavement, but also can reduce the asphalt or cement pavement thickness, in order to save costs.For road slope and dam reinforcement and retaining wall: the traditional embankment especially filling high embankment filling and often need to shoulder edge easy compaction, resulting in slope rainwater invasion, collapse instability phenomena have occurred, but with a gentle slope, covers an area of large, the retaining wall has the same the problem of using geogrid embankment slope or retaining wall reinforcement can be reduced by two points a area, prolong service life, reduce the cost of 20 - 50%.

- Q: Which floor is paved on the roadbed

- Fixed grid end, by laying machine or manual will grill slowly pulled forward each shop, shop 10 meters long artificial investigation at a time, until a volume grating puwan, put the next volume, operation with; 3, ground shop: Volume long unit as the laying of the long, should be covered grille with long period, then the overall check again laying quality, then laying the next paragraph, a laying, grille grille to overlap a grid spacing for the lap length, tie fixed line continues to spread second section direction.

- Q: Can geogrids be used in reinforcement of rock slopes?

- Yes, geogrids can be used in the reinforcement of rock slopes. Geogrids are commonly used to stabilize and strengthen slopes by improving the stability and increasing the bearing capacity of the soil or rock. They are effective in preventing slope failures and erosion, and can be installed in combination with other methods such as rock bolts or shotcrete to provide additional support and reinforcement to the rock slope.

- Q: How do geogrids improve the performance of geosynthetic-reinforced embankments?

- Geogrids improve the performance of geosynthetic-reinforced embankments by providing tensile strength and reinforcing the soil, thereby increasing stability and load-bearing capacity. They distribute lateral forces and reduce settlement, preventing slope failure and soil erosion. Additionally, geogrids enhance the overall durability and longevity of the embankment structure.

- Q: What is the tgsg15-15 geogrid

- The single belt is formed by the longitudinal and horizontal spacing or the clamping arrangement, and the welding joint is formed by adopting the welding technology of special strengthening bonding to weld the joint.

- Q: Can geogrids be used in green wall systems?

- Yes, geogrids can be used in green wall systems. Geogrids provide structural reinforcement and stability to the soil, which is essential for supporting the weight of the green wall. They help prevent soil erosion, improve drainage, and increase the overall strength of the system, making them a suitable choice for incorporating into green wall installations.

- Q: Why steel plastic geogrid in the test, will choose to peel out a single wire test? What are the causes and sources of this method?

- Because the main force borne by the steel wire, if it is false, the consequences can be disastrous ah!

- Q: How do geogrids enhance the performance of geosynthetic clay liner capillary barriers?

- Geogrids enhance the performance of geosynthetic clay liner capillary barriers by providing additional reinforcement and stability to the liner. They help distribute loads more evenly, increase tensile strength, and reduce the potential for deformation or failure of the liner system. Additionally, geogrids assist in controlling lateral movement and prevent the loss of clay particles, ensuring better long-term performance and effectiveness of the capillary barrier.

- Q: Can geogrids be used for reinforcement in landfill liners?

- Yes, geogrids can be used for reinforcement in landfill liners. Geogrids are commonly employed in landfill applications to enhance the stability and strength of liner systems. They provide additional support to the liner material, preventing deformation and improving its overall performance and longevity.

- Q: How do geogrids help in reducing the risk of slope instability?

- Geogrids help in reducing the risk of slope instability by reinforcing the soil and providing additional strength to the slope. They act as a stabilizing agent by increasing the soil's shear resistance and preventing it from sliding or collapsing. This reinforcement helps in distributing the forces exerted on the slope, reducing the potential for slope failure and improving overall stability.

Send your message to us

Slope Reinforcement Geogrids - Good Toughness Polyethylene Geogrid High Strength Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords